Hide categoriesShow categories

Our range of products and services that we offer within the sectors:

More than 125 years of Krebs & Riedel – Innovative grinding technology since 1895.

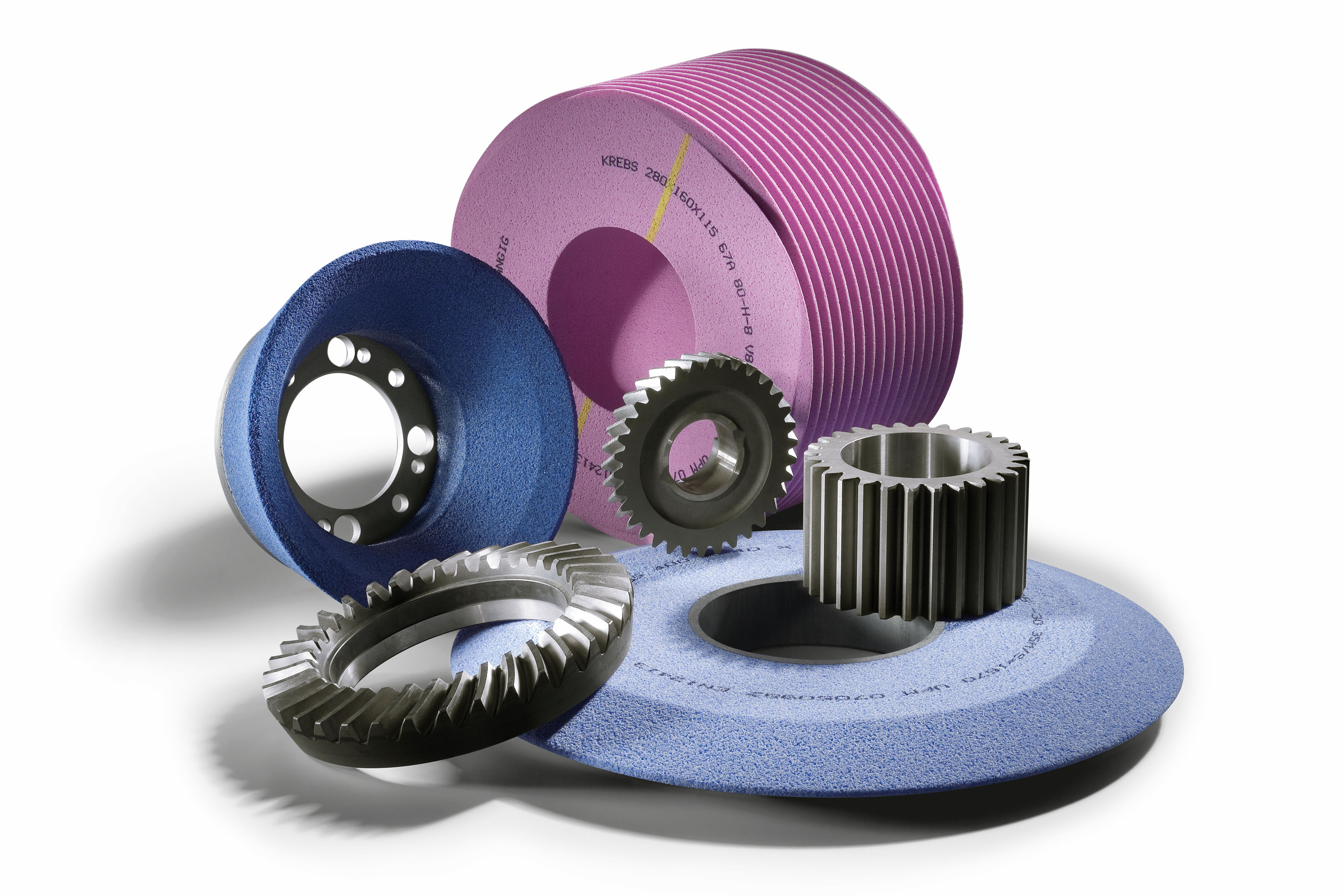

The cornerstone of the Krebs & Riedel grinding wheel factory in Bad Karlshafen was laid some 125 years ago. Today the family-owned company operates worldwide as a manufacturer of individually manufactured precision grinding wheels and impresses with innovation and solution-oriented application technology advice. Above all, customers from the automotive, aerospace, mechanical engineering, medical technology and wind power sectors rely upon the high-precision products manufactured by Krebs & Riedel. In addition to conventional grinding wheels, cutting wheels, cup grinding wheels and grinding segments with ceramic and synthetic resin bonds, Krebs & Riedel also manufactures CBN and diamond tools with ceramic bonds, as well as honing rings. The medium-sized family business with over 250 committed employees has an annual turnover of 31 million euros. Krebs & Riedel is one of the global innovation leaders in abrasives and has subsidiaries in China and India and a strong distribution network in more than 30 countries worldwide.

Diverse portfolio, individual products and special solutions with special quality requirements.

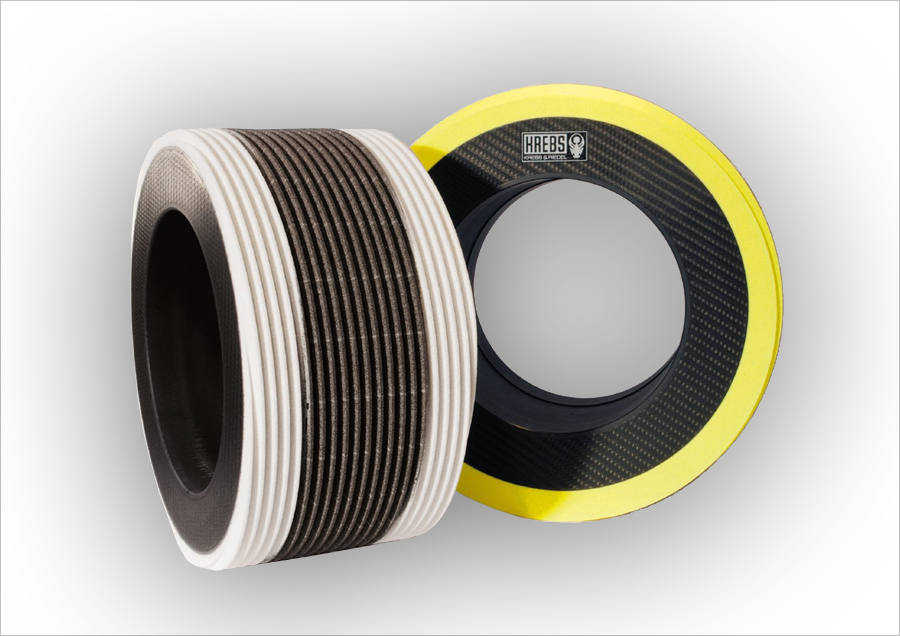

At Krebs & Riedel, high-quality products are created with special quality standards and maximum safety. Krebs & Riedel is a member of the VDS (Verband Deutscher Schleifmittelwerke e.V.). As a founding member of the oSa (organization for the safety of abrasives), safety comes first. The production program includes corundum and silicon carbide wheels with a ceramic bond and synthetic resin bond for most industrial grinding applications up to 900 mm outside diameter for round, flat, tool, centerless, gear and rough grinding applications. Cut-off wheels in synthetic resin bond with and without fiber reinforcement up to 800 mm outside diameter for chop cut, pendulum cutting and rotary cutting. Roughing and pendulum grinding with and without fibre reinforcement for the cleaning shop and the foundry industry; Grinding wheels for pendulum grinding machines, grinding wheels for bench grinders and grinding wheels for grinding manipulators. Diamond and CBN grinding media in vitrified bond with a working speed of up to 200 m / s for internal, flat, circular, tool grinding and special grinding processes.

Krebs & Riedel is a specialist in gear applications.

Krebs & Riedel is a specialist in the field of gear applications and supplies top gear manufacturers around the globe. These grinding wheels are used on many gear grinding machines, including those from the manufacturers Gleason, Kapp-Niles, Klingelnberg, Liebherr, Mitsubishi, Reishauer and Samputensili.

For customers in the automotive industry, aerospace, mechanical engineering, medical technology and wind power, Krebs & Riedel offers the right tools for the perfect machining of gears in continuously reliable quality. Our experience ranges from grinding the smallest gears in the field of medical technology to large planetary gears in wind turbines.

From continuous generating grinding to single profile grinding and bevel gear grinding to power honing, we also offer customized grinding solutions. Whether you want to increase your productivity, improve tool life or optimize your surface finishes, you can rely on Krebs & Riedel's consistent grinding performance.

Product informations

Krebs & Riedel offers users advanced grinding wheels which are specifically tailored to the desired process.

- Grinding Wheels in Vitrified Bonds

- Grinding Wheels in Resin Bonds

- Cutting and rough grinding wheels

- Grinding segment

- Internal grinding wheels

- CBN and Diamond Wheels in Vitrified Bond

![[Translate to English:] InDiamond.world](/fileadmin/_processed_/a/1/csm_InDiamond_Logo_2021_1fb017de30.png)