Aluminum - one material, numerous machining solutions

Drilling, reaming, grooving and milling: Paul Horn GmbH in Tübingen offers a wide portfolio of optimized tools for the economical machining of the light metal aluminum (AI). Every day we come into contact with aluminum (Al). In packaging, in cars, in electronics or in mechanical engineering. After steel materials, aluminum is the most commonly used metal.

There is hardly an area of technology and everyday life in which aluminum alloys are not used. In the machining industry, Al alloys are among the materials that are easy to machine. Nevertheless, it is possible that machining the soft metal can quickly produce a "hard lump". Sticking, built-up edges and chip jams up to tool breakage occur. With the right tools, cutting materials, cutting data and the right quantity and type of cooling lubricant, Al alloys can be reliably machined.

Aluminum smelters worldwide produce more than 60 million tons of the light metal per year. Global demand for this metal has risen sharply in recent years - not least due to the dynamic development in Asia. China has the largest production output of aluminum, at over 30 million tons per year. After oxygen and silicon, aluminum is the third most abundant element on earth with a share of 8%. However, it does not occur in pure form in the earth's crust. The metal is extracted from weathering products of lime and silicate rocks - bauxite. The raw material for aluminum production has a high aluminum oxide content of over 50%. The Bayer process can be used to extract pure aluminum oxide from bauxite. However, this is still so fine that it behaves almost like a liquid. Only when the oxide and the mineral cryolite are melted does the mixture break down into liquid aluminum and oxygen. This process is called fused-salt electrolysis.

Professional tuning

The tensile strength, elongation, hardness and strength of Al can be influenced by alloying elements such as silicon, magnesium, copper, zinc and manganese. During machining, the material can become soft due to heat generation, the cutting tool can stick and it can also be destroyed due to the disturbed chip flow. It is therefore important to match the material and cutting parameters properly. It depends on the Al alloy, the cutting tool, the cutting material, the feed rate and speed, and the type and quantity of cooling lubricant.

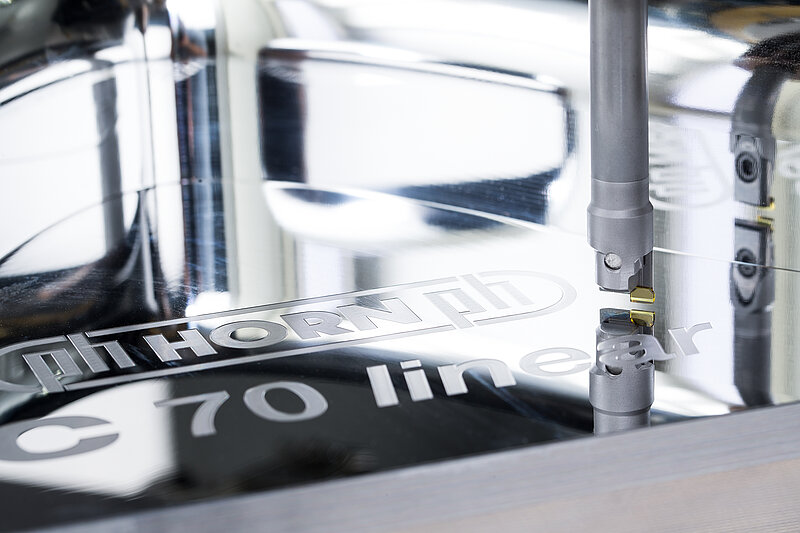

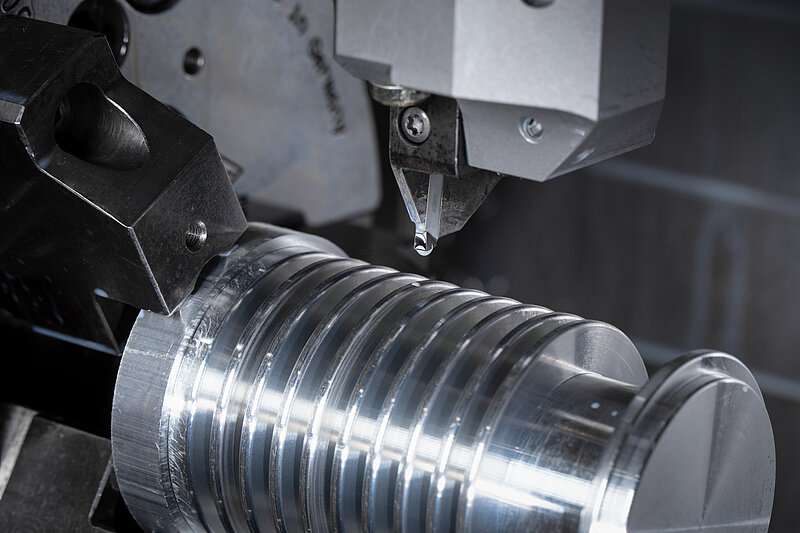

Due to the strong adhesion tendency of Al, the most important features of the Horn tool program of standard and special tools are special chip shape geometries with sharp cutting edges, polished rake faces as well as coatings with very good sliding properties. Carbide inserts for grooving are also given a peripheral grinding to ensure an extremely sharp cutting edge. For Al alloys with high silicon content, the inserts are PVD coated. For milling, coated and uncoated circular tools and solid carbide cutters are in the portfolio. Due to the large chip volume based on high cutting data, single-edged milling cutters with large chip space are also used. High hardness cutting materials such as PCD and CVD-D with lasered cutting edges and chip shape geometries are available for long service life or more complex work. MKD-tipped tools are used, for example, for high-gloss machining of mirrors or Al blow molds.

Grooving with polished rake faces

One machining example is the parting of cooling fins of a pump housing from the medical technology sector. The material used was an aluminum alloy with a low silicon content, which is difficult to machine due to the long chips and the built-up edges that form. In solving the task, the Horn technicians relied on the S224 grooving system with the chipforming geometries FY and WA. Basic holders with a clamping cassette and internal coolant supply through the chip finger as well as through the support are used to hold the cutting inserts.

The FY geometry is used to rough the cooling fins and a wide recess. The shape of the geometry causes controlled breakage of the chips, and the coolant pressure prevents the chips from melting on the rake face. The special WA aluminum grooving geometry ensures the high surface quality of the component when finishing the grooves. The polished chip shape geometry counteracts built-up edge formation, produces small spiral chips and thus ensures good chip control and high process reliability.

Tools equipped with monocrystalline diamonds are used to produce the highest surface finishes on workpieces made of aluminum or other non-ferrous alloys. The range of applications for high-gloss machining is wide. Especially in tool and mold making, the process saves polishing work and at the same time increases the quality in flatness and surface finish. Thus, the process is used where the surface of the mold is reflected in the parts to be manufactured.

For the machining of a wall spout prototype, a user received an order to deal with high-gloss machining. The order came from a manufacturer of premium fittings. The clear geometries and flat surfaces of the prototype design require machining with MKD. Deviations in the surfaces and geometry would be visible through later chrome plating. Because of these quality requirements, polishing after machining was ruled out, as small irregularities in the surface would immensely affect the refraction of light in the chromium layer, which is only a few micrometers thick. The user did not have much time to find the solution to the machining task. The difficulty in machining the blank, which was cast from brass, was the long projection length of about 200mm. Horn solved the problem with an MKD-tipped ISO insert. The roughness (Rz ≤ 0.01μm) required by the designers of the valve manufacturer could thus be achieved through the strict quality controls.

Due to its smooth surface and the low adhesion tendency thereon as well as the high wear resistance, polycrystalline diamond (PCD) is also very well suited for machining aluminum alloys. In addition, the sharp cutting edges enable a high achievable surface finish. In addition to turning operations, the cutting material is also used for drilling. Due to the high achievable cutting parameters, PCD-tipped drilling tools enable shorter process times and longer tool lives compared to solid carbide drills. PCD drilling tools are therefore frequently used in series production, for example in the drilling of aluminum rims.

![[Translate to English:] InDiamond.world](/fileadmin/_processed_/a/1/csm_InDiamond_Logo_2021_1fb017de30.png)