Glass grinding to perfection in one go: processing of glass with Squadro-G

Squadro-G, the diamond grinding pad from Microdiamant for advanced glass processing.

Technological progress in fine grinding, lapping, and polishing is essential for international competitiveness. The goal: faster, more efficient, and even more precise - reducing costs and increasing efficiency with advanced grinding solutions. The challenge is finding the most profitable process that also meets the highest quality standards. The combination of these two aspects has now been achieved by Microdiamant with its new innovative Squadro-G grinding pad for all common glass-like materials.

"The decision to develop grinding pads for glass was a strategic step to establish our Squadro grinding pads for new applications and to grow in these markets," says Martin Spring, CEO of Microdiamant. "Our assessment is that there is a manageable number of suppliers for fine grinding of glass and optical materials; in any case, there is a lot of interest from customers for new solutions," Martin Spring continues.

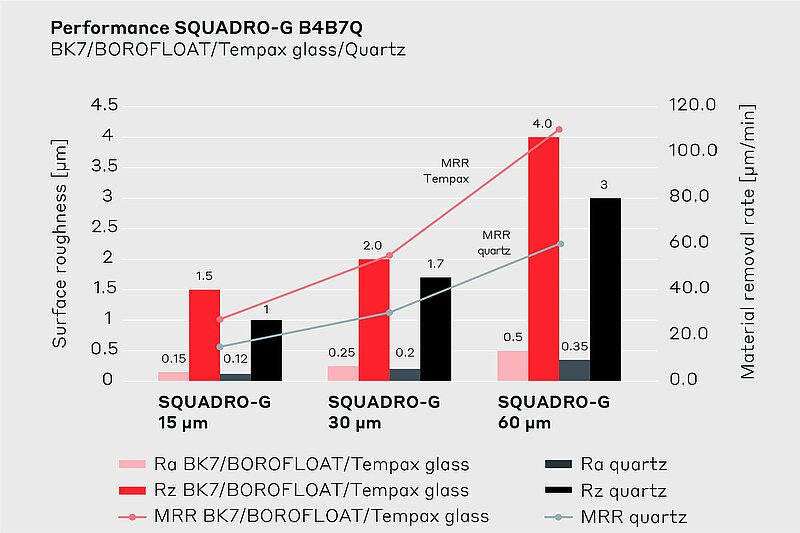

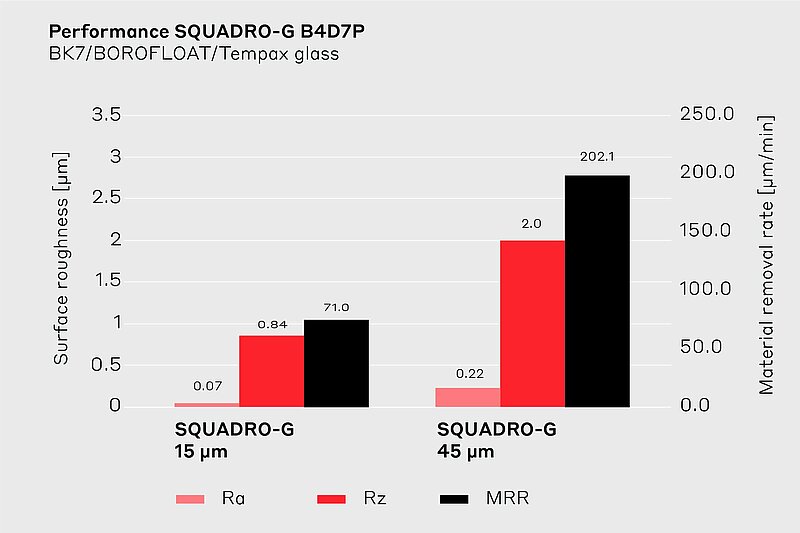

Squadro-G is a highly efficient diamond grinding pad, suitable for fine grinding of optical glass, BK7, quartz glass, glass ceramics as well as crystalline or brittle glassy materials. It achieves a high, uniform stock removal over the entire service life as well as impressive edge sharpness and surface finishes of up to Ra 0.07 microns. The grinding pad convinces users thanks to its high flexibility to quickly and easily change and mount pads with different grit sizes (from 60 to 3 microns). For this purpose, Microdiamant offers a special Teflon support to avoid long machine downtime when removing the grinding pad - making the process even more efficient. These features make Squadro-G an economical and efficient alternative to thin abrasive films or conventional lapping processes. Squadro-G not only offers a clean and fast abrasive process with easy handling and cooling, but the grinding pad also delivers excellent results in all important areas: speed, quality, flexibility and lifetime.

"When developing Squadro-G, our biggest challenge was to bring a product to market that meets the high demands of customers in the precision industry. Here, the most important factors are axial run-out, a high surface quality, a long service life, excellent adaptation of the pad to the respective process and a high level of occupational safety during the process",

explains Helge Willers, Productmanager and Sales Director at Microdiamant.

In the Surface Lab application laboratory, Microdiamant application engineers develop and optimise fine grinding, lapping and polishing processes for and with customers. As a total supplier, the company produces solutions that are used in a wide range of industries such as precision, electronics and optics, medical technology, tool manufacturing and coatings, as well as in the luxury goods industry.

![[Translate to English:] InDiamond.world](/fileadmin/_processed_/a/1/csm_InDiamond_Logo_2021_1fb017de30.png)