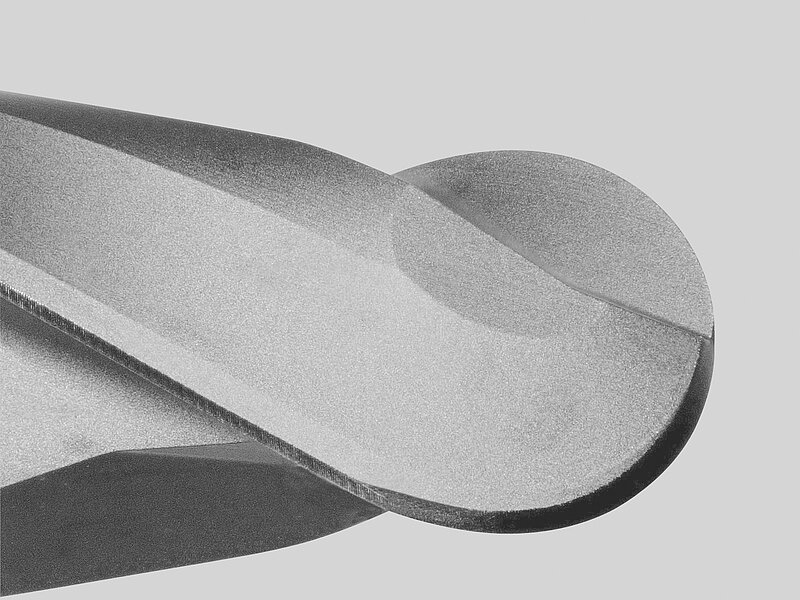

Iguana – Evolution 2.0 – helical fluting included

Zecha has been manufacturing micro precision tools for 55 years now and has many years of experience in hard machining and diamond coating.

And this is the ideal starting point for making innovative tools that employ existing know-how and cutting-edge coating technologies. The machining of non-ferrous metals such as copper or high performance copper alloys and delicate contours and superb surfaces requires tried-and-tested tools such as the high-end Iguana mill cutters from Zecha Hartmetall-Werkzeugfabrikation GmbH from Königsbach-Stein. These solid carbide tools with high wear resistance, sealed diamond coating and laser-cut, sharp cutting edges master the challenge with gusto. The latest developments in the Iguana tool family are two helical fluted lines: the 930 milling cutter series and the 975 twist drill series.

Optimisation of the laser process has enabled Zecha to manufacture the Iguana series with integrated helix. The almost freely selectable helical fluting of the tools promises great improvements in further areas of use. Materials difficult to machine such as medical (fibre-reinforced) plastics or lead-free brass alloys can be ideally machined thanks to the positive helical characteristics - softer cut, rounded groove forms, improved chip removal etc. The new helical fluted milling cutters are available as dual flute ball or torus milling cutters in diameters ranging from 0.5 mm to 3.00 mm. In addition, Zecha also offers a triple-fluted shaft milling cutter in diameters of 1.0 mm to 6.00 mm. All three versions in the 930 series are suitable both for wet and dry machining. The uniform geometric conditions across the entire cutting edge length produces an even softer, burr freer cut and the optimum chambers ensure excellent chip removal and machining results.

Innovation – Iguana drills

Apart from the new helical fluted high end Iguana milling cutters, Zecha has also introduced a solid carbide micro twist drill with diamond coating and laser-sharpened cutting edges to its tool range. The Iguana twist drills have a digressive helix with right-hand cutting direction and are self-centring due to the X drill point located on the drill head. These drills, just like the Iguana milling cutters, have been furnished with a laser-machined, sealed high performance diamond coating with edge protection and are available in diameters ranging from 0.8mm to 2.0 mm.

Conclusion

The high-end Iguana series efficiently masters the typically encountered challenges such as precision, tool life and manual reworking. The line increases productivity, as it results in less tool changeover and thus also lower downtimes. Iguana tools machine to a very good geometric accuracy and produce virtually no burring, which is great advantage as regards process capability. Nevertheless, it is always true to say that only the perfect interplay of man, machine and tool can achieve a perfect result.

![[Translate to English:] InDiamond.world](/fileadmin/_processed_/a/1/csm_InDiamond_Logo_2021_1fb017de30.png)