Mastering processes: High-polish machining

Mirror-finish surfaces and roughness to within nanometres. These are properties that can only be achieved with the process of ultra-precision machining or high-polish machining. Using the right precision tool with the appropriate grade ensures the perfect result. The surface produced is always a mirror image of the cutting edge of the tool. Thanks to its internal structure and hardness, only a cutting edge made of monocrystalline diamond (MCD) can be polished finely enough for an absolutely flawless surface to be produced during cutting. There are no computer-aided machines for perfect polishing of a flawless cutting edge. Only the expert touch and knowledge of specially trained employees can guarantee this high-polish result. The finishing of top-class tools is a purely manual task.

High-polish machining with MCD is one of the ultimate disciplines in the field of machining with geometrically defined cutting edges. Two hundredths of a millimetre of finishing allowance separate a very good surface from a perfect surface with mirror finish. The range of applications is broad and the manufacturing process is used in numerous industries. In the jewellery industry, the tools provide dazzling shine; for example, in the production of visible parts for quality wristwatches and most wedding rings. In the production of mirrors for space telescopes, the virtually perfectly accurate shape of the milled mirror surface guarantees a distortion-free view into space. Diamond-tipped tools have been used in the manufacture of almost every vision aid, from glasses to contact lenses. Another possible application is tool, model and mould making. This is an area where time-consuming and expensive polishing can be saved. The list goes on, not least in the medical sector, where these tool systems are firmly established.

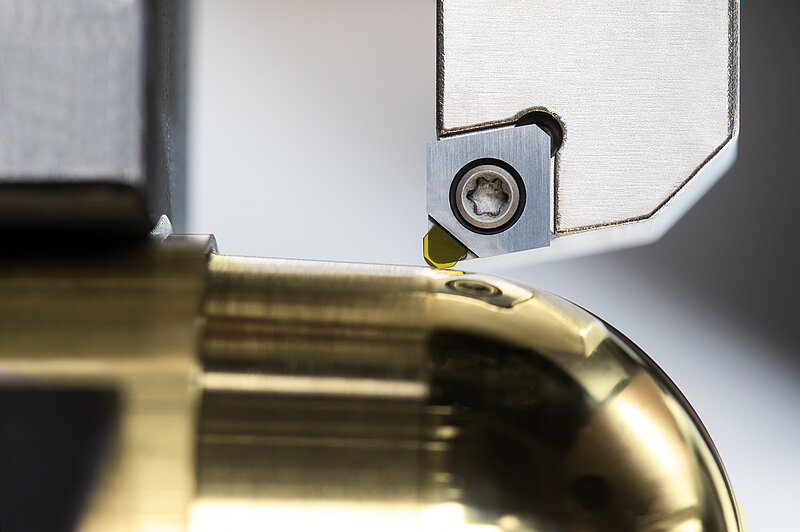

For turning a wall-mounted tap prototype, a user was commissioned by a manufacturer of premium fittings to look into high-polish machining. The clean geometry and flat surfaces of the prototype design require machining with MCD. Irregularities in the surface and geometry would be visible through the subsequent chrome plating. Due to these quality requirements, polishing after machining was ruled out, as even slight irregularities in the surface would hugely affect the reflection of light from the chrome layer, which is only a few microns thick. The user did not have much time to find the best solution to this machining task. The difficulty in machining the brass casting was the long projection length of around 200 mm. Horn found a solution using an MCD-tipped ISO cutting insert. The surface finish required by the valve manufacturer's designers could then be achieved through strict quality control.

Applications in research

In scientific fields, researchers hope to gain new insights with the help of mirrors with high-polish, precision surfaces. One example is a group of astrophysicists at the University of Kassel. In a vacuum chamber, the scientists are creating materials that otherwise only exist in outer space in order to learn more about how stars grow and decay. Sophisticated laser systems and high-precision mirror systems aid the researchers in investigating their ideas and theories. In the research, laser beams are directed via the mirrors through a gas cloud that has been created. The more often the beam is reflected back and forth, and therefore the more often the beam passes through the gas, the clearer the detected signals become. Before high-polish machining, researchers relied on polished mirrors. These had a mirror-like surface, but there were too many geometric inaccuracies affecting the smoothness due to the number of times it had been polished. MCD-tipped milling cutters were able to overcome these issues.

high-polish surfaces can also be produced on non-specialised, universal machining centres. The bearings of the drives and the spindle play a decisive role in this. high-polish machining is limited to non-ferrous metals, precious metals and fibre-free plastics. Its economical application in steels is not possible due to chemical interaction. In use, the carbon in the diamond would diffuse into the iron in the steel and dissolve the diamond.

Craftsmanship

In order to produce high-polish surfaces, the quality of the tool cutting edge plays a decisive role. The quality of the cutting edge is reflected in the surface to be machined. The final grinding or polishing of the MCD cutting edge takes real craftsmanship. Similarly to when cutting a diamond for jewellery, finish grinding of a tool cutting edge for high-polish machining is carried out by hand. What’s more, air-bearing grinding tables with a table top made from solid granite provide optimum conditions for grinding the cutting edges. A microscope with 200x magnification is used for visual inspection. Under this magnification, the cutting edge must be absolutely free of any imperfections. The resulting cutting edge has a maximum radius of 0.0002 mm (7.8740157e-6"). Horn has developed a special grinding machine for grinding MCD ball nose end mills for high-polish machining of freeform surfaces, with which even the smallest radii can be ground reliably.

It is mainly synthetic diamonds that are used for high-polish machining. Two different methods can be used to produce synthetic stones. In the HPHT (high pressure, high temperature) method, the diamonds are created under elevated levels of pressure and heat, meaning they are created in an almost natural way, only not over millions of years, but within a few hours or days, depending on the desired size. Using this method, pure graphite powder is converted into a diamond at a pressure of 60,000 bar and a temperature of 1,500 degrees Celsius (2,732°F). Diamonds created using this method are characterised by a slightly yellowish colour, which is caused by the refraction of light from embedded nitrogen atoms. The maximum edge length of the synthetic stones is 10 mm (0.394"). Dimensions beyond this are theoretically possible, but would not be economical.

Horn uses even purer MCC diamonds for MCD tools. These monocrystalline stones are created using the CVD method. Various gases (mainly methane) are used to provide the carbon source and are separated during the process to allow the diamond to grow. These diamonds are characterised by their crystal-clear to slightly brownish colour, depending on the thickness. A major advantage of this method is the feasible edge length of the stones, as even longer tips with cutting edge lengths of 30 mm (1.181"), for example, can be achieved. Before these methods were implemented, natural diamonds had to be used for such tools, which was difficult due to their high price, lack of availability and natural inclusions.

Source | Horn / Sauermann

![[Translate to English:] InDiamond.world](/fileadmin/_processed_/a/1/csm_InDiamond_Logo_2021_1fb017de30.png)