Norton Winter optimises tool grinding

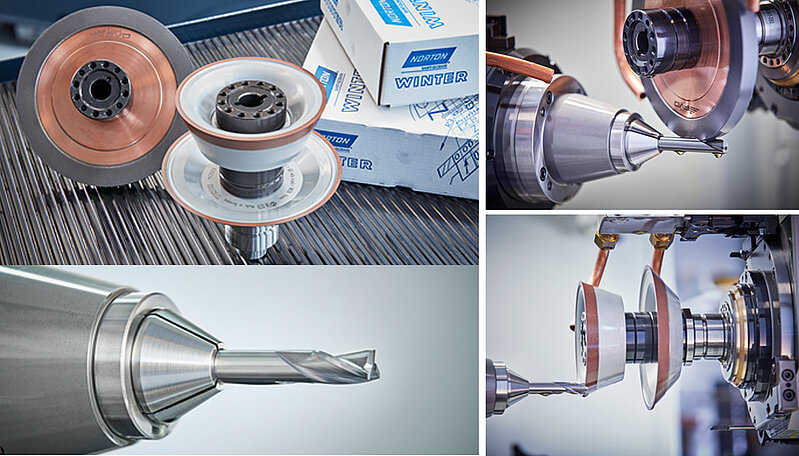

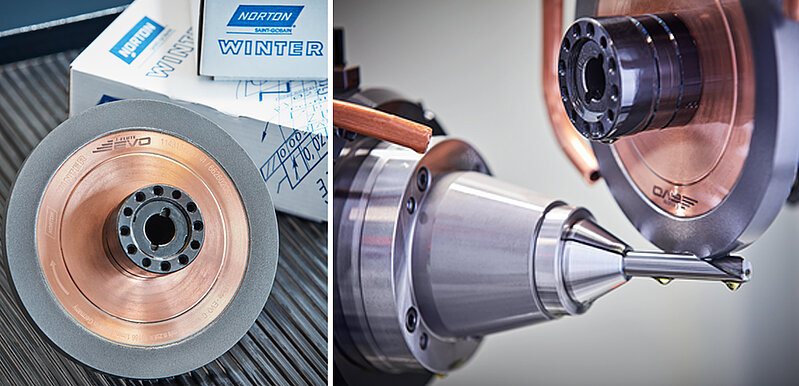

Q-Flute-Evo: tool ‘evolution’ for flute grinding of small and medium-sized tool batches.

The Norton Winter Q-Flute grinding wheel range complete with Q-Flute2 and application optimized Q-FluteXL bond types never fails to impress tool grinders. It gives consistently superb finish at high outputs delivering economical flute grinding in both Carbide and High Speed Steel tool grinding operations. We now have in addition to this bond family a new high performance Q-Flute-Evo grinding wheel. With this new development Saint Gobain Abrasive has combined the successful performance of Q-Flute2 and Q-FluteXL resulting in a more flexible bond. This is important for medium and small tool size production batches where the process requirements call for a product that is easy to use, effective and attractively priced.

Modern grinding tools need high edge stability as well as very free and cool grinding to ensure short process times and minimal wear during flute grinding. The requirements of grinding tools also vary at the application level. In addition to volume production, the trend toward ever smaller batch sizes are taking hold right across the industry. So, not only do flute grinding tools need to be designed for high performance, but it is also vital that they can be used flexibly and efficiently in a broad range of applications. Norton Winter has developed the new Q-Flute-EVO to fulfil these requirements.

Flexible, effective and attractively priced

The new Q-Flute-Evo flute grinding wheel combines the excellent properties of the tried and tested Q-Flute2 and the Q-FluteXL tool family, thereby offering a unique combination of free grinding behaviour and profile stability. This in turn forms the basis for its uncomplicated and flexible application in tool production. For instance, the Q-Flute-EVO can be used both at a low removal rate (Q‘w ≈ 3) and at high performance (Q‘w ≥ 6).

Ronald Hörmann, Product Manager for Resin Bonds at Saint-Gobain

Abrasives, says that the Q-Flute-Evo meets the demanding performance requirements perfectly, particularly when it comes to grinding small and medium sized batches, thanks to its optimised bond properties and excellent price performance ratio.

Impressive in practice

In comparison with similar high performance products on the market, Q-Flute-Evo grinding wheels reduce grinding force by up to 20%, according to Norton Winter. They also achieve excellent edge stability. This prolongs service life and minimises downtime. The high grinding quality is reflected in the flutes outstanding surface finish.

The benefits of the new bond specification become apparent in practice. For example, the grinding of Carbide cutters and drills with diameters of 3 mm to 16 mm demonstrates the impressive flexibility of the Q-Flute-Evo, which can be used here on a broad range of products, replacing four grinding wheel specifications. The Norton Winter grinding tool boasts excellent edge stability and better self-sharpening properties than similar wheels, which extends the dressing interval significantly overall.

‘With the Q-Flute-Evo in combination with Norton Winter V-Prime diamond grinding wheels, tool manufacturers have access to a high-performance duo for complete machining that ensures outstanding productivity in shank tool production. Tool manufacturers can respond flexibly with predictable production security thanks to the short delivery times for our Q-Flute and V-Prime products, which are available in a wide range of shapes and sizes.’

as Ronald Hörmann says, Product Manager Resin Bonds at Saint-Gobain

High-performance duo for complete machining

In addition to perfect flutes thanks to the Q-Flute-Evo, Norton Winter V-Prime diamond grinding wheels for sharpening and clearance angle grinding ensure optimal complete machining. V-Prime combines the extreme edge stability of a hybrid or metal bond with the free grinding behaviour of standard resin bonds as well as their trouble free dressing and profiling capabilities. V-Prime tool grinding and regrinding therefore make it possible to maintain the wheel geometry for as long as possible without the need for adjustment and thereby offering increased output and improved quality.

![[Translate to English:] InDiamond.world](/fileadmin/_processed_/a/1/csm_InDiamond_Logo_2021_1fb017de30.png)