Hide categoriesShow categories

Our range of products and services that we offer within the sectors:

Our products and services that we offer for tool manufacturing. Tools for the industries.

Ceratonia supplies diamond and CBN cutting material for the tool manufacturing industry since 1996. With 15 employees, Ceratonia is supporting medium-sized companies and global players producing diamond and CBN tools for wide-ranging applications worldwide in different sectors. Their own production cuts polycrystalline diamond materials on laser systems to ensure very fast delivery times.

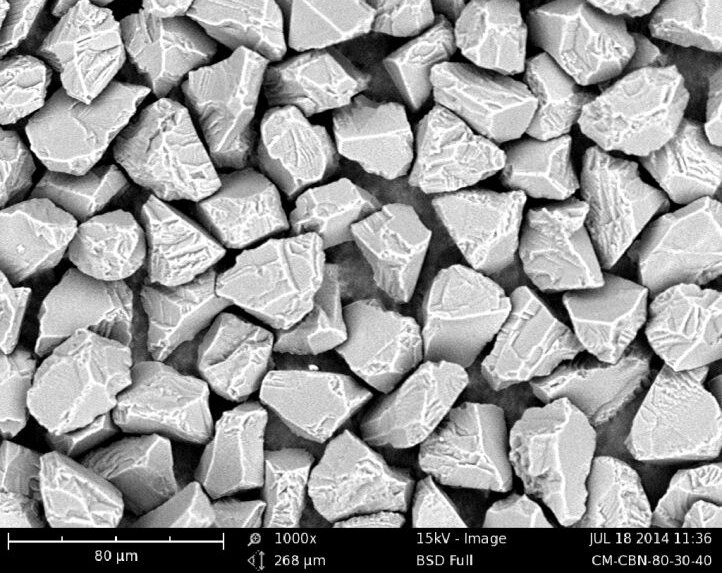

Ceratonia also offers diamond grit in a size range of nanocrystalline diamond powder to diamond grit in several millimeters diameter. The product range includes synthetic grit as well as natural grit in monocrystalline and polycrystalline composition. The super abrasive products are manufactured in HPHT (High Pressure – High Temperature) process and in CVD (Chemical Vapour Deposition) process.

Ceratonias Customers

...produce diamond and CBN-tools. They supply the stone-, wood-, glass-, ceramic-, the metal-working and construction industry as well the natural stone industry. Further sectors are the medical technology, refractory materials and special tools which are used e.g. in restoration.

Company philosophy

New products are a challenge but also a chance for new applications and markets. We intend that our customers are always one step ahead through using our high quality diamond and CBN-types and to increase their competitiveness together with us. Our target is to provide the determining advantage in competition and to obtain it. We manage that by an attractive relation between price, quality and service.

We are interested in the suggestions and inquiries of our customers. We consider it as our duty to keep our customers informed about the latest state of diamond and CBN-development. Furthermore we consider it as our duty to optimize the communication and dispatch routes between production and application.

Our quality policy

Ceratonia recognizes the responsibility for quality management, health protection and accident prevention, and environmental protection as an integral part of its management function. We see this responsibility and the implementation of appropriate quality standards as key to successful corporate management.

By involving all employees and cooperating with production, a properly documented quality management system according to DIN EN ISO 9001:2015 has been implemented.

Product informations

Natural Diamond

- NATGRIT CN-P: crushed and whole crystals

- NATGRIT CN-WS: whole crystals called Whole Stones

- NATURAL DRILLS: whole crystals respectively stones slightly rounded

- NATGRIT Longs-processed: needle-shaped stones tumbled

Diamond grit synthetic

- CERAGRIT CNF: saw diamond

- CERADIA CNF and CMG/CMG-E: abrasive grit (also coated)

- DIAZON: abrasive grit

CERAMIKRON Diamond Micron Powder

- Micron powder - natural and synthetic

CERAMIKRON Micron Powder CBN

- CBN-Micron powder, 3 types with different toughness fracture behaviour

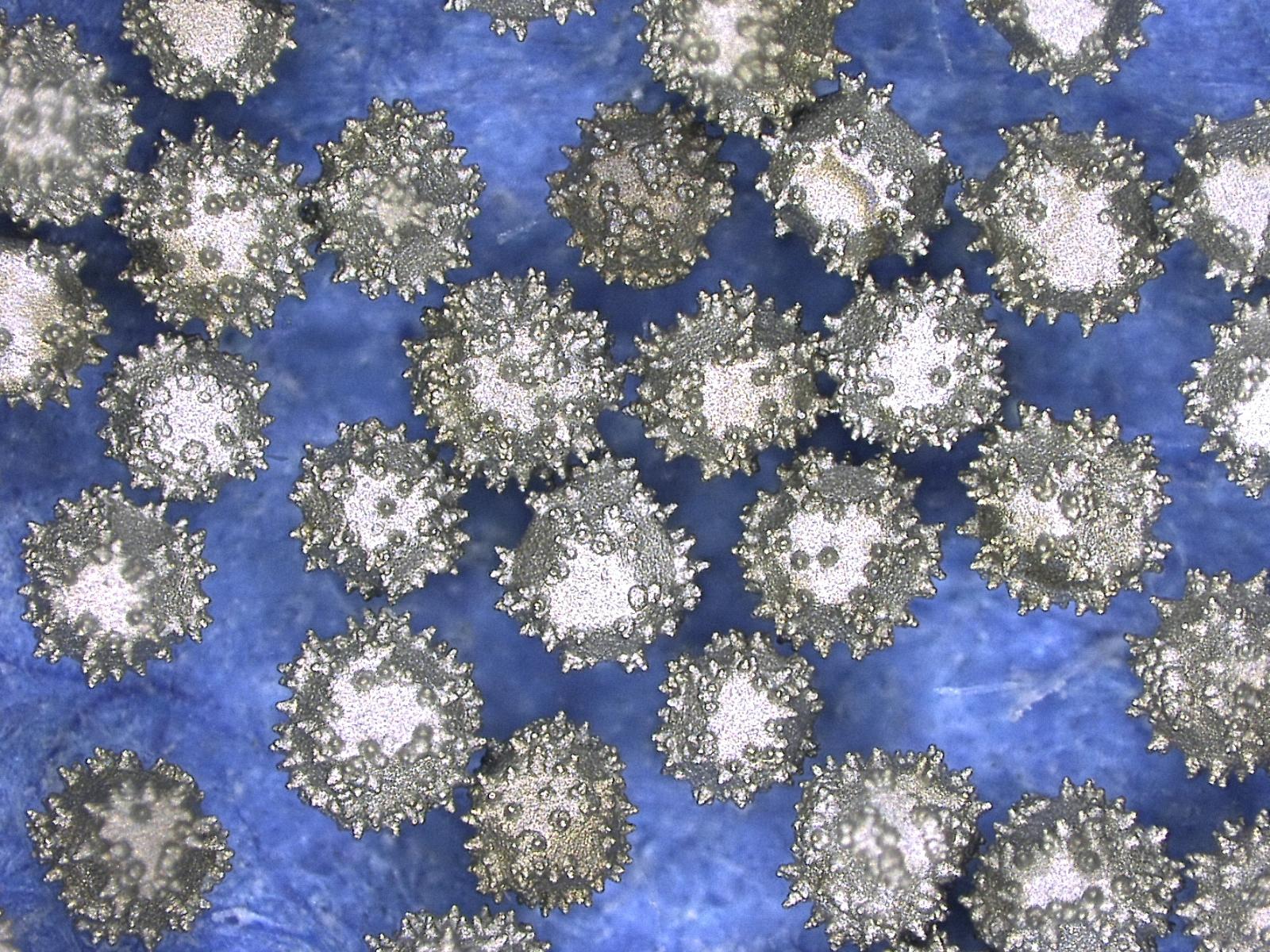

CBN Abrasive Grit

- CERABON: family with 8 types of CBN abrasive grit

Polycristalline Diamond CVD

- CERADRESS-CVD: dresser (0,3 mm till 2,3 thickness)

- CERATON-CVD: for machining (0,3 mm till 1,0 mm thickness, mat and polished)

- CERAPIN-CVD: diamond sticks (round, till 2,3 mm length)

- CERACUBES-CVD: diamond thick film in cube form

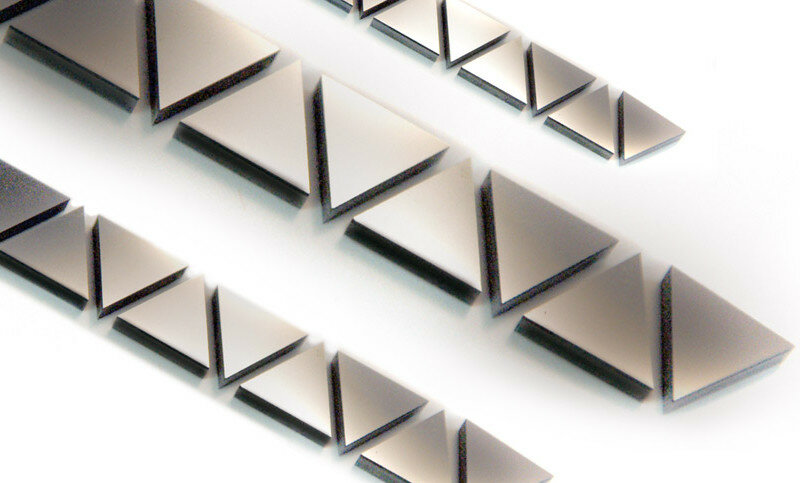

Polycristalline Diamond PCD

- CERASET: Solid-PCD (without carbide) – heat resistant for dressers

- CERADITE: PCD in different grain sizes on carbide for machining

- CERAPAX: PCD, 3- layers; (carbide/diamond/carbide); for drills

- CERADIE: PCD for drawing dies

Monocristalline synthetic stones (HPHT manufacturing process, yellow)

- SYMONOSTONES: synthetic Whole Stones

- SYMONODRESS: dresser sticks

- SYMONOPLATES: laser cutting blanks for machining and dressers

Monocristalline synthetic stones (CVD manufacturing process, bright, gray till white)

- MONO VD: single crystal; for machining and dressers

Laser machining

- Laser cutting of CVD thick film

- Laser marking / laser engraving

High vacuum furnace – brazing of diamond and pCBN tools

![[Translate to English:] InDiamond.world](/fileadmin/_processed_/a/1/csm_InDiamond_Logo_2021_1fb017de30.png)