Hide categoriesShow categories

Our range of products and services that we offer within the sectors:

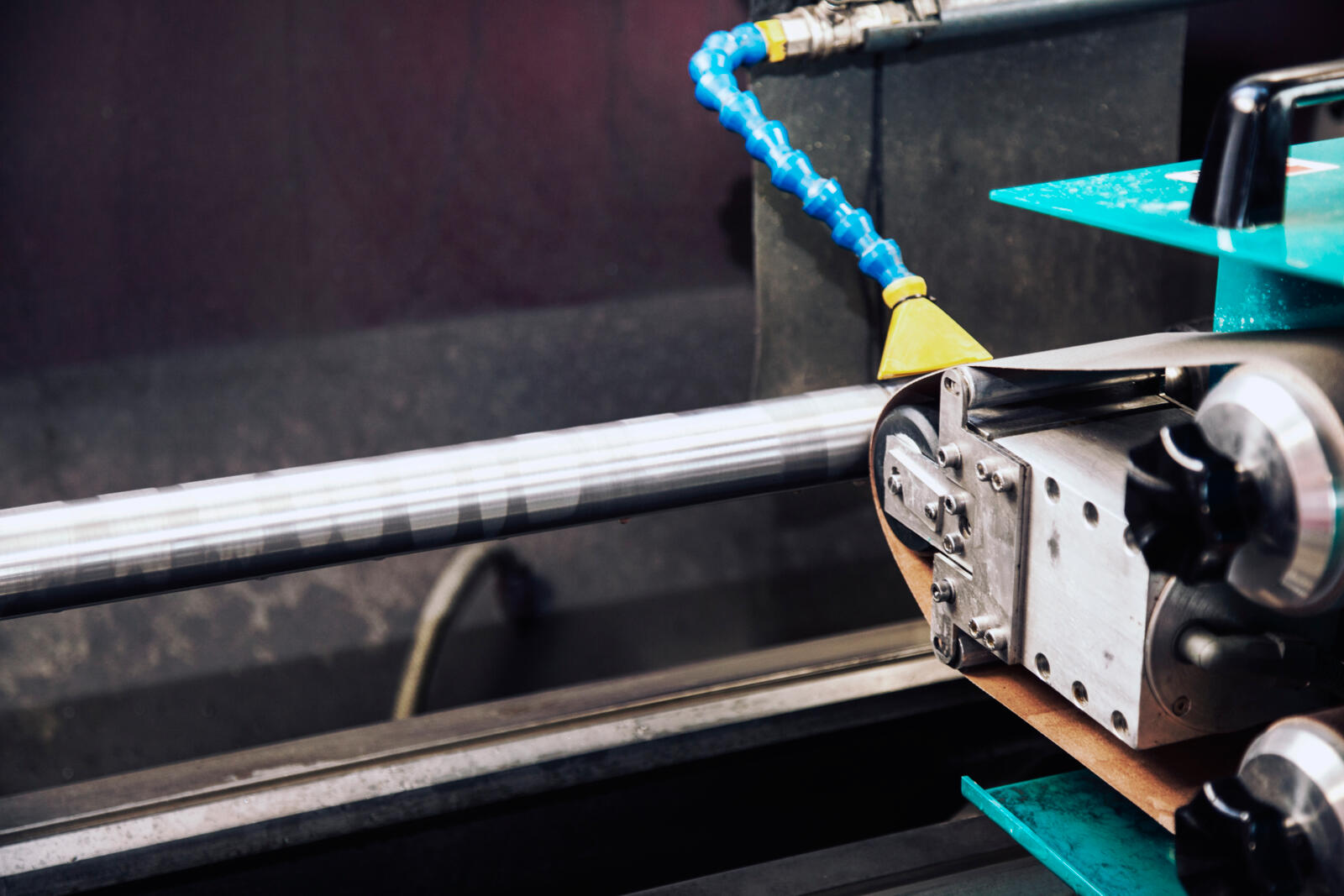

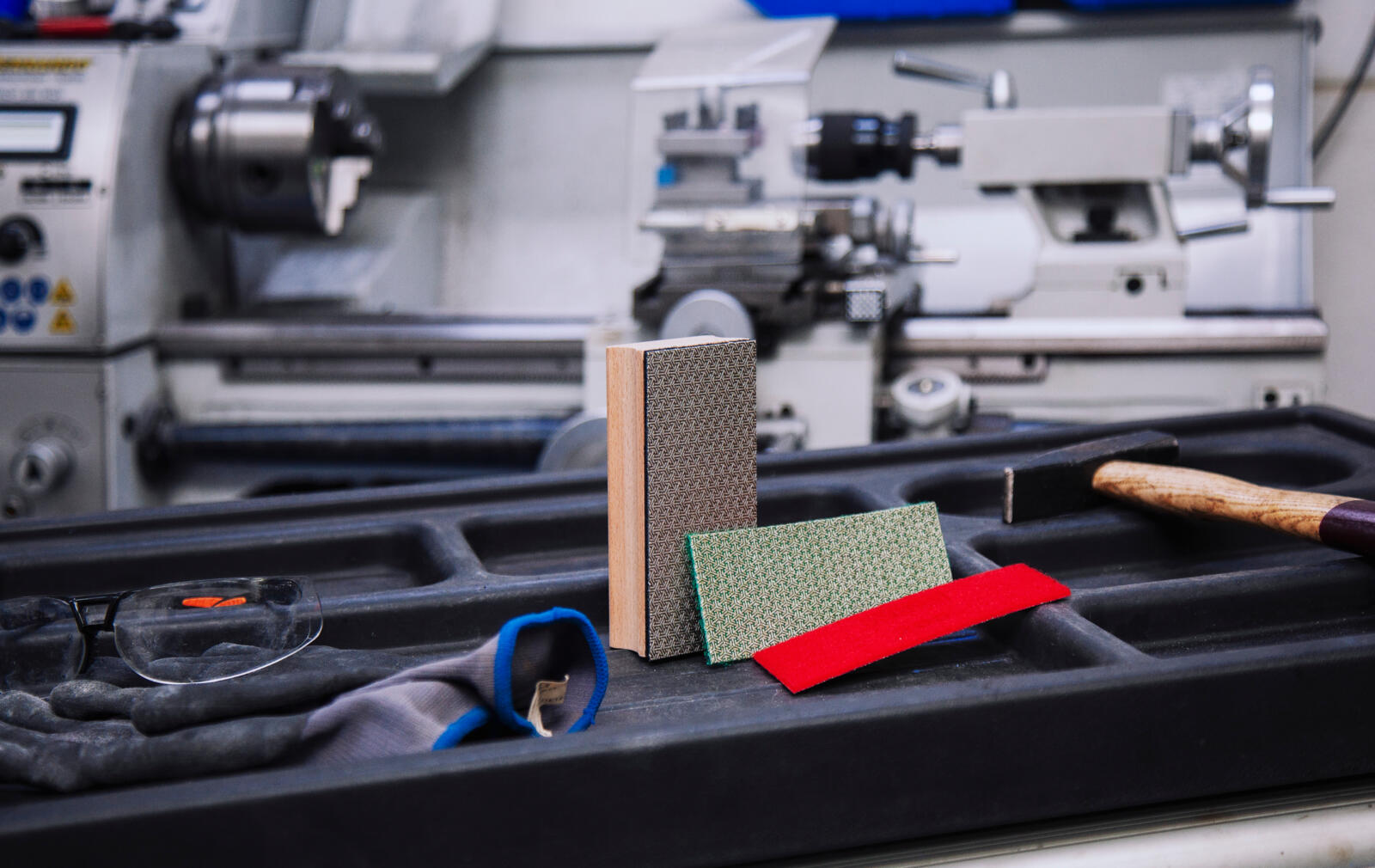

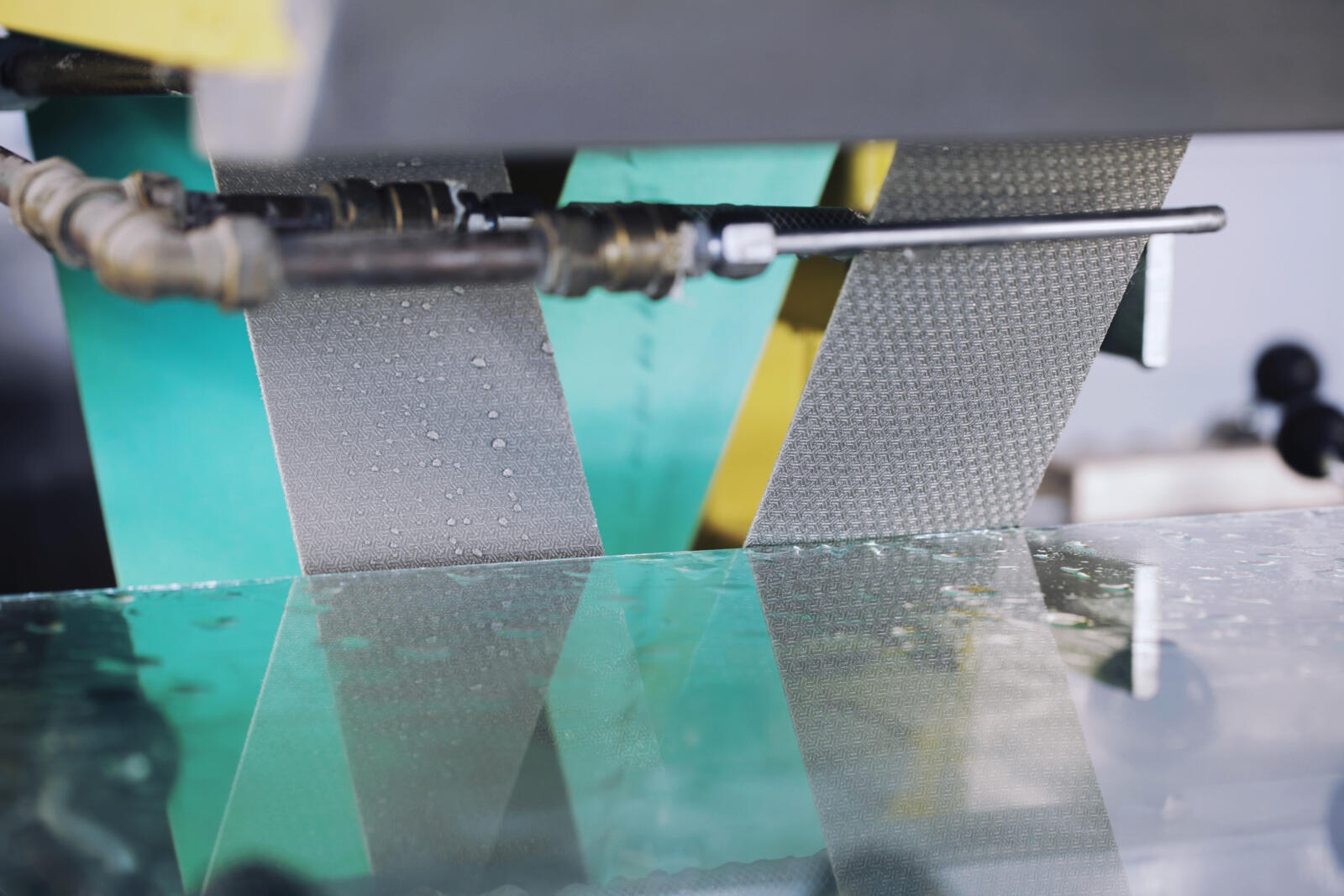

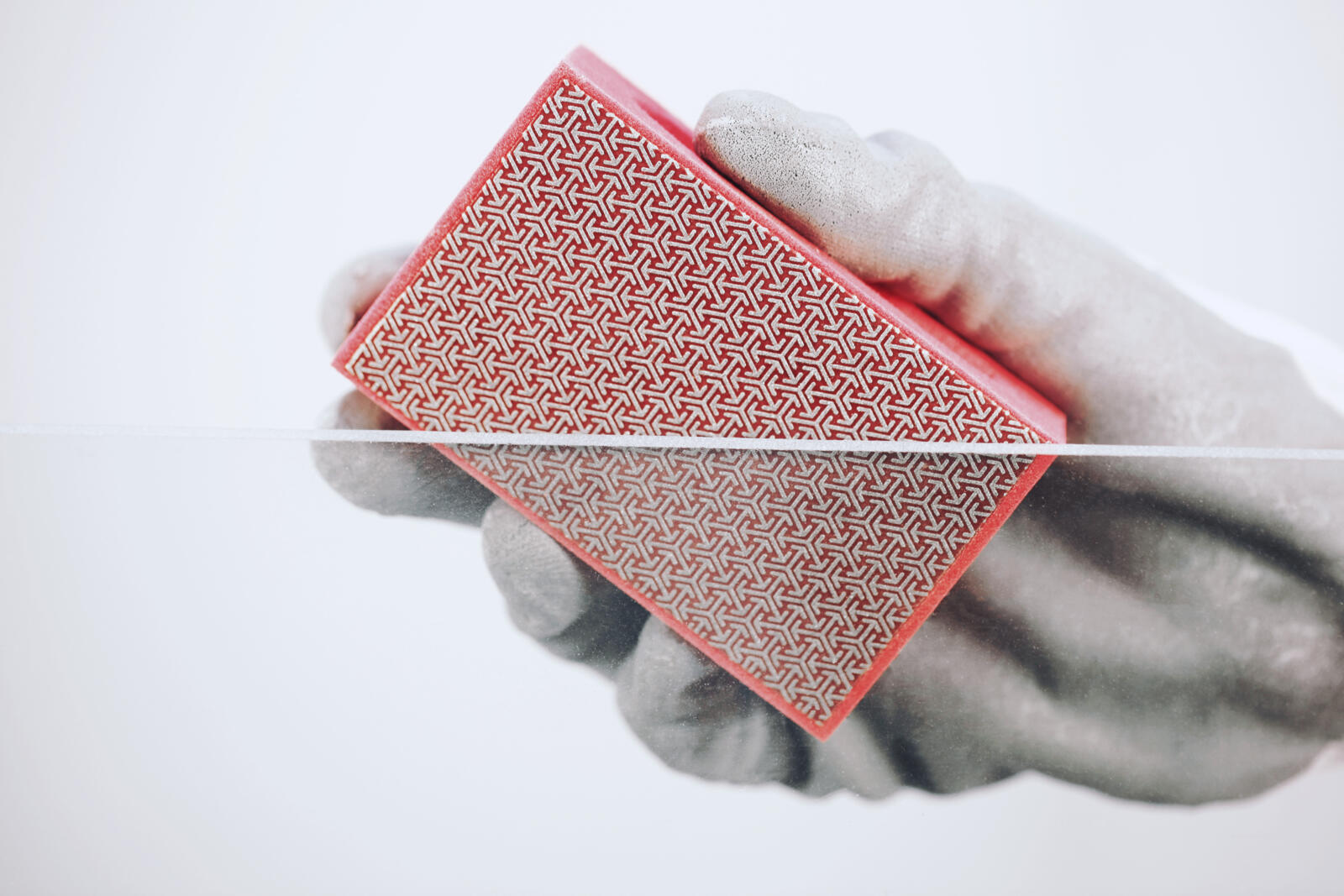

Starting in 1906 as a Swiss family owned, cement moulding company, KGS, since 1952 has transformed into a world leading flexible diamond abrasives company. KGS, for the past 67 years, has been manufacturing premium flexible diamond abrasives for grinding and polishing of hard, brittle materials. Flexible diamond belts for stripping, dimensioning and finishing cylindrical parts, dry grinding of yankee rolls, strips for superfinishing machines, quick change discs for turbine blade polishing, a range of discs for metallography, polishing of complexe shapes like mud rotors and extrusion spirals. A full range of product shapes for glass edging and foot polishing of porcelain cups and plates. Various solution for grinding and polishing composite materials.

KGS is located in 15 countries and on 4 continents, including 6 factories and 20 sales offices. Production is based mainly in our European factories. Our products are used in many markets such a glass, stone & construction, ceramic, super hard coatings, composites and porcelain.

We supply solutions to industries such as automotive, aviation, railway, aerospace, dental, watches, porcelain, glass, ceramics, composites, stone and construction, telecommunication, oil and gas and wind power.

KGS specializes in the design, support and production of customer specific flexible diamond tools. Their application engineers will work closely together using the experience and expertise of the R&D and production department to define the optimum solution for your special project creating an unique product specification.

Special shapes, density of diamond, backers, bonds are used to suit your demand, application and provide you with a tools in line with performance requirements, expected lifetime and costs. Our production technologies are especially well suited to small lot size, engineered solutions. The technical superiority combined with unique products, allow us to offer innovative solutions with high added value and in perfect harmony with market requirements.

It is within our mission to provide you with the ultimate solution - adapted to your process - to reduce the abrasive costs and providing higher quality results. We do this based on our experience in combination with in-depth analysis of your process requirement, proposing you an optimal concept for your grinding set-up.

Six reasons why you should use flexible diamond tools:

- More user friendly; less noise

- Consistent performance; thanks to the high mechanical resistance of diamond

- Better results; No chipping, no breakage

- Save time; Less downtime of machine, means higher output

- Save money; Thanks to the long service life

- More environmentally friendly; less waste

![[Translate to English:] InDiamond.world](/fileadmin/_processed_/a/1/csm_InDiamond_Logo_2021_1fb017de30.png)