Hide categoriesShow categories

Our range of products and services that we offer within the sectors:

Company description

We succeeded in becoming a competent partner as regards truing technique using diamond tools with a special attention to truing technique using diamond rolls.

In June 1967 the Steinmetz Schleiftechnik Enterprise was founded by Alois Steinmetz in Großwelzheim, designed for a modern and economic profiling of grinding wheels using truing devices with profiled diamond-coated rolls. With skill, energy and competence he was able to guide the enterprise through its difficult early years. The union of the community Großwelzheim and the neighbouring community Dettingen to form the new community Karlstein, took place at July 1st 1975 with the regional reform in Bavaria. When the enterprise was taken over by the son Michael Steinmetz at July 1st 1990, the increased experience was combined with youthful dynamism. Planning of our new company site took place from November 1998 to January 1999. Construction of the building and laying out of the site took place from March1999 to November 1999. Finally in December 1999 the new facilities with 450 m² of office space , 450 m² production and assembly space on a total area of 2000 m² could be used, thus creating the conditions for the further development of the company. Since 1967 Steinmetz truing devices with diamond rolls, mandrels for diamond rolls, truing spindles and diamond truing equipment are successfully used for all kinds of grinding problems.

The next step was taken on 18th June 2013 when we were certified according to DIN EN ISO 9001.

On 1st April 2014, we changed the company name to "Steinmetz Schleiftechnik GmbH & Co. KG", a Ltd. & Co., with Michael Steinmetz being the executive manager. Since January 2018, Mister Thomas Rohé, who has been an employee of Steinmetz Schleiftechnik for many years, has taken over the company. Mister Steinmetz will continue to direct the company as its CEO in collaboration with Mister Thomas Rohé for the next few years and assist him with his decades of experience. Nonetheless, Mister Rohé will contribute with his own innovative ideas to the success of the company.

Over 10000 Steinmetz truing devices and grinding spindles are installed all over the world. Our competent technicians and more than 50 years of experience in truing and grinding technology enable us to provide an optimized solution for any truing and dressing problem. We are able to achieve this high degree of precision provided by our products due to the high motivation and qualification of our staff and due to the use of state-of-the-art production machinery. Our diamond roll arbors, dressing units, radius dressing devices, dressing spindles and grinding spindles stand out because of highest precision.

Product informations

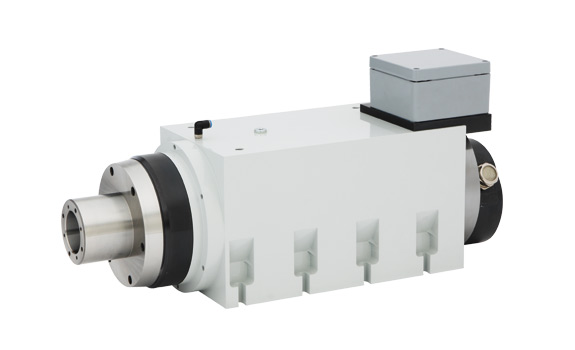

Description for the Roller Dressing Spindle

Due to our decades of experience and development work, we supply today dressing spindles conforming to today's most demanding requirements. Smooth run and excellent concentricity and traverse run of at max. 2 µm characterise our precision dressing spindle. It is fitted with a specially developed bearing of the highest precision with grease lubrication. The dressing spindle is designed for dressing CBN and conventional grinding wheels. The well proven design assures a long service life.

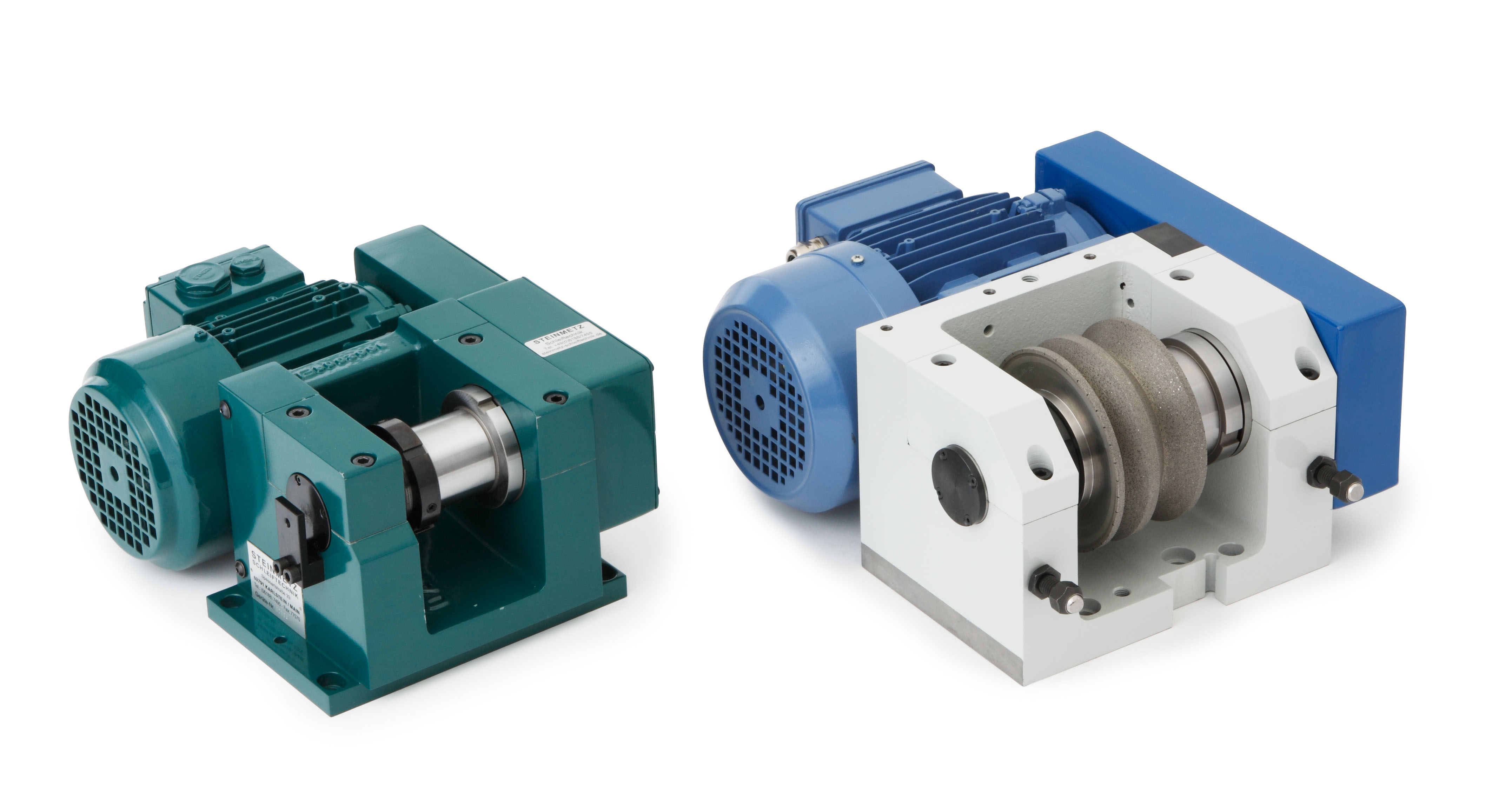

Description for Diamond Roller Dressing Unit

Our truing devices with diamond rolls fulfill the specific requirements for diamond truing rolls. Performance and accuracy of the grinding wheel truing operation are decisively determined by the truing device in which the diamond truing roll is used. Our truing devices are distinguishing themselves by a rigid design. Good damping capacity is guaranteed due to the basic construction in annealed cast-iron (GG25). The diamond roll is driven by an asynchronous motor, a three-phase motor, or a hydraulic axial piston motor.

The asynchronous motor may be controlled up to a frequency of 100 CPS using a frequency converter. The mandrels for diamond rolls may be grease-lubricated for life or oil-mist lubricated. The sense of rotation is ad lib, the device may be used for clockwise or anti-clockwise operation. Quick changing of the diamond roll together with the mandrel for the diamond roll is possible. The maximum admissible radial and thrust run-out amount to 2μm. For every diamond roll a diamond roll mandrel should be provided, thus changing of the diamond roll is facilitated and speeded up.

![[Translate to English:] InDiamond.world](/fileadmin/_processed_/a/1/csm_InDiamond_Logo_2021_1fb017de30.png)