Zecha Hartmetall-Werkzeugfabrikation GmbH

Hide categoriesShow categories

Our range of products and services that we offer within the sectors:

ZECHA Hartmetall-Werkzeugfabrikation GmbH has been a pioneer and trendsetter in the field of micro cutting, blanking and forming tools for over half a century. The company's origins in the chronograph industry can be seen not only in its uncompromising specialisation in the production of miniature tools of the highest precision, but also in its special tool solutions.

Precision and quality are key for the international employment in different industries, such as, for example, in medical and dental technology, the chronograph industry, automotive industry, or in tool and mould making. Experts in the company's own research and development department are constantly developing ground breaking geometries and tools for sophisticated applications and cutting-edge materials.

In addition, tool reproducibility is also guaranteed even for years on account of the life number stamped at the end of the shaft of every tool.

Modern CNC machines, high-end measuring and testing technologies and carefully selected hard metals from leading manufacturers as well as an intensive cooperation with our customers and partners ensure the exceptional perfection of our Tools.

ZECHA manufactures products that meet the highest quality demands. As an accredited company according to DIN EN ISO 9001:2015 quality management is firmly embedded in all processes at ZECHA and this ensures a consistent high level of quality.

Product information

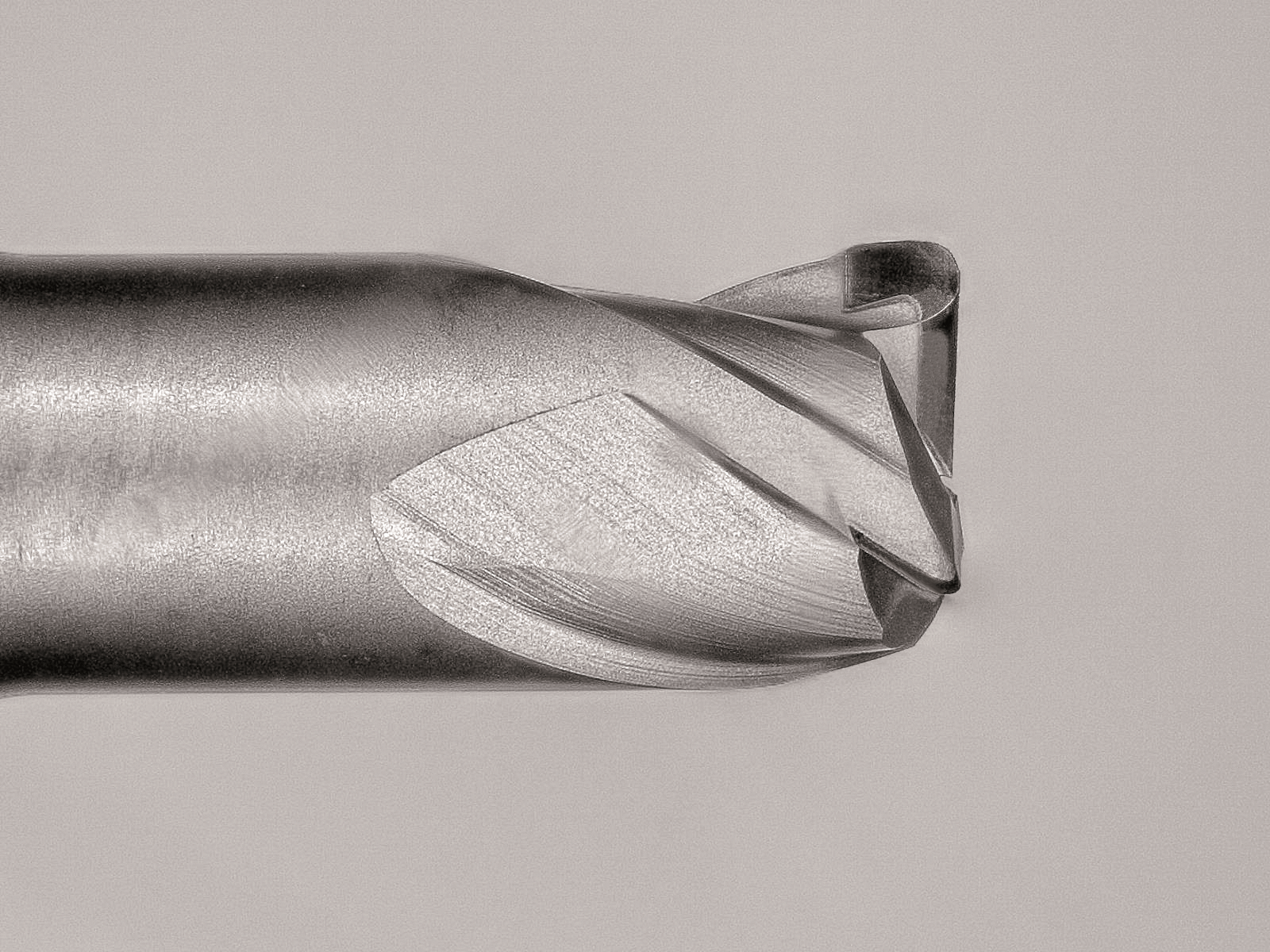

IGUANA

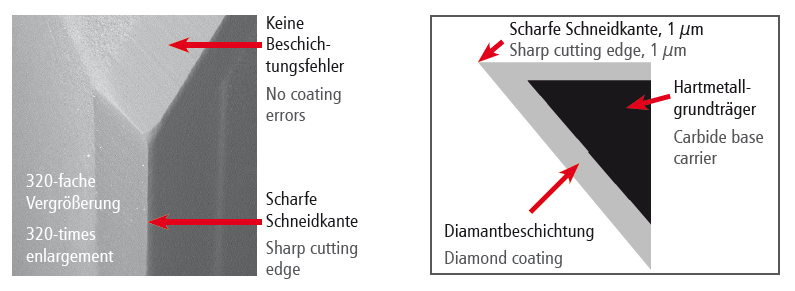

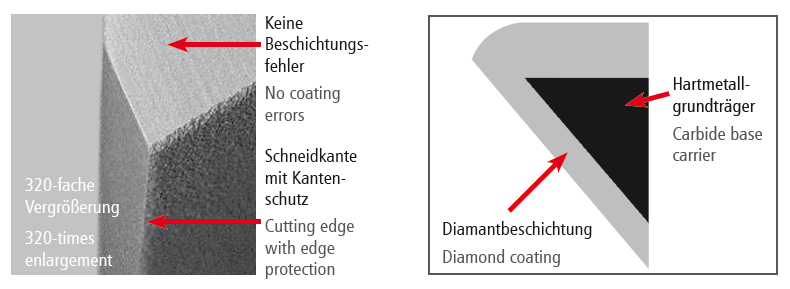

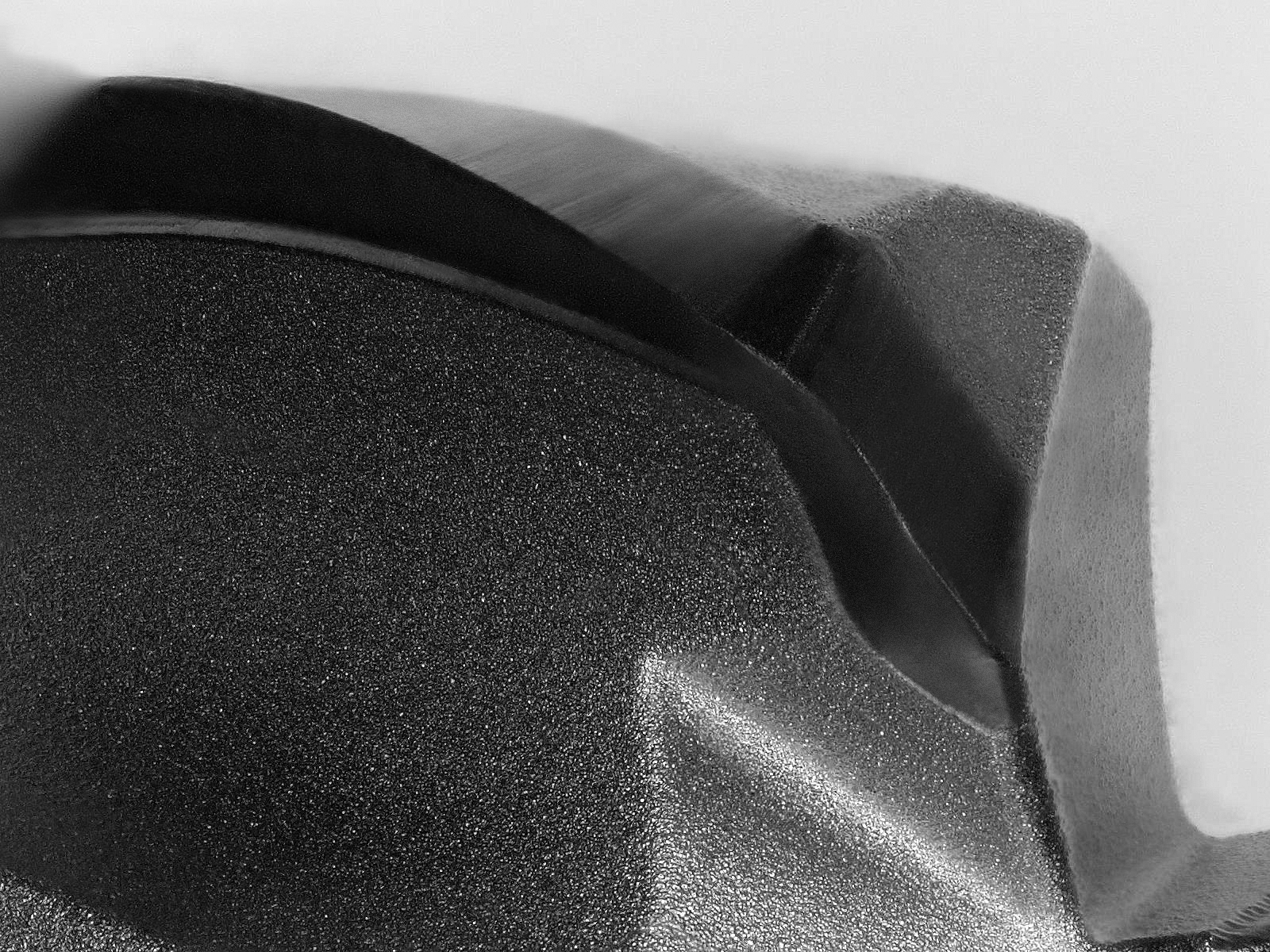

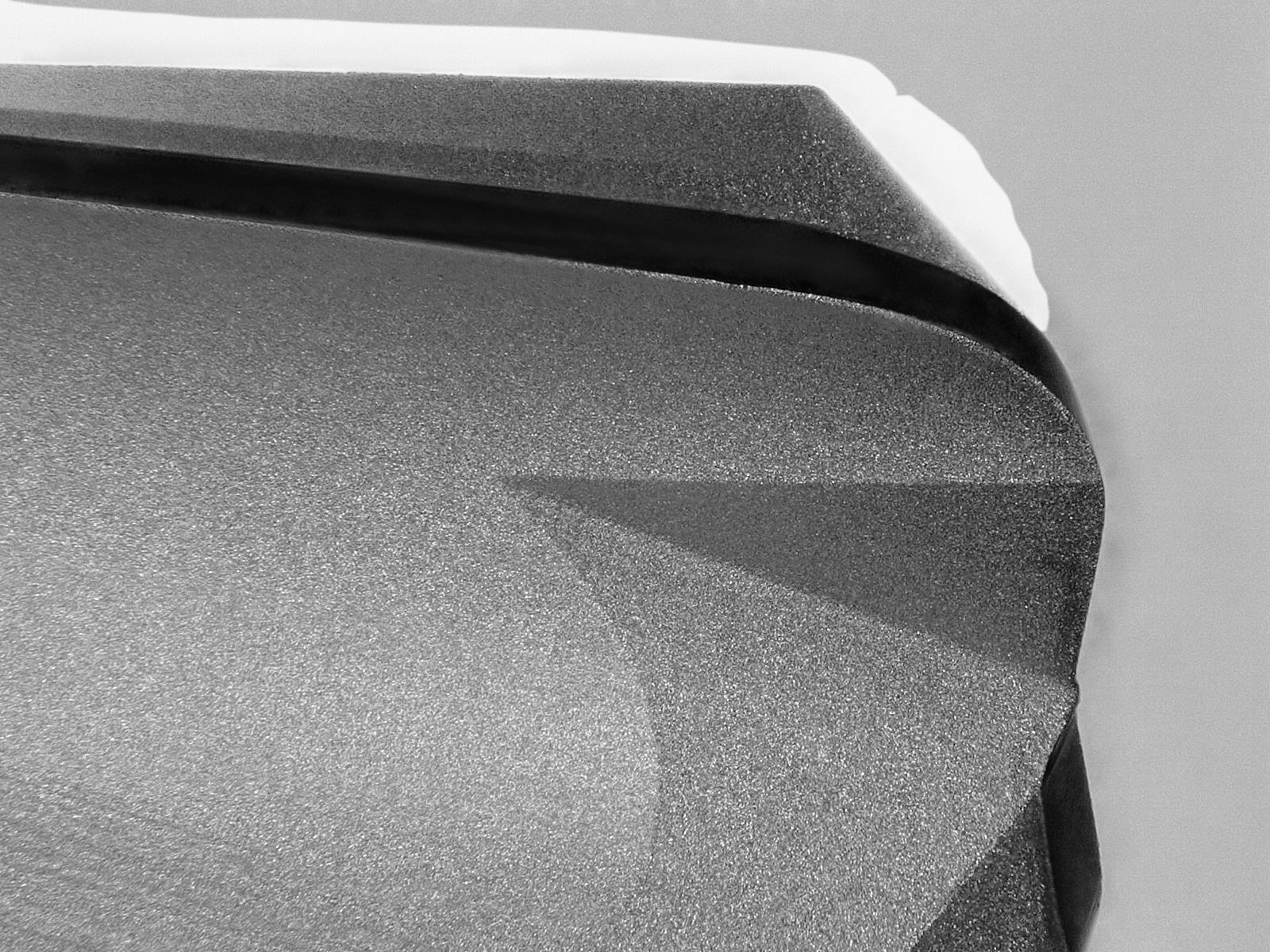

In comparison to our competitors’ tools, ZECHA’s IGUANA tools offer a 400-fold longer tool life in copper and a multiple longer tool life in fibre-reinforced PEEK and lead-free brass because of their unique fusion of technologies. Awarded Baden-Württemberg’s 2021 Innovation Prize, ZECHA’s unique IGUANA technology sets new standards worldwide in the field of precision tools. Thanks to the innovative laser processing of the diamond coating, its small diameter multi-cutters shine brightly as a result of their extreme sharpness, extreme wear resistance, very long service life and very high process reliability. Thanks to various design options – spiralled, lasered on both sides, with or without a cooling system – this tool family can be used to machine a wide range of applications and the most demanding materials with smooth surfaces and a performance of the highest quality.

![[Translate to English:] InDiamond.world](/fileadmin/_processed_/a/1/csm_InDiamond_Logo_2021_1fb017de30.png)