MASTER OF TURNING HEADS

Significantly reduce set-up times with flexible interchangeable milling heads

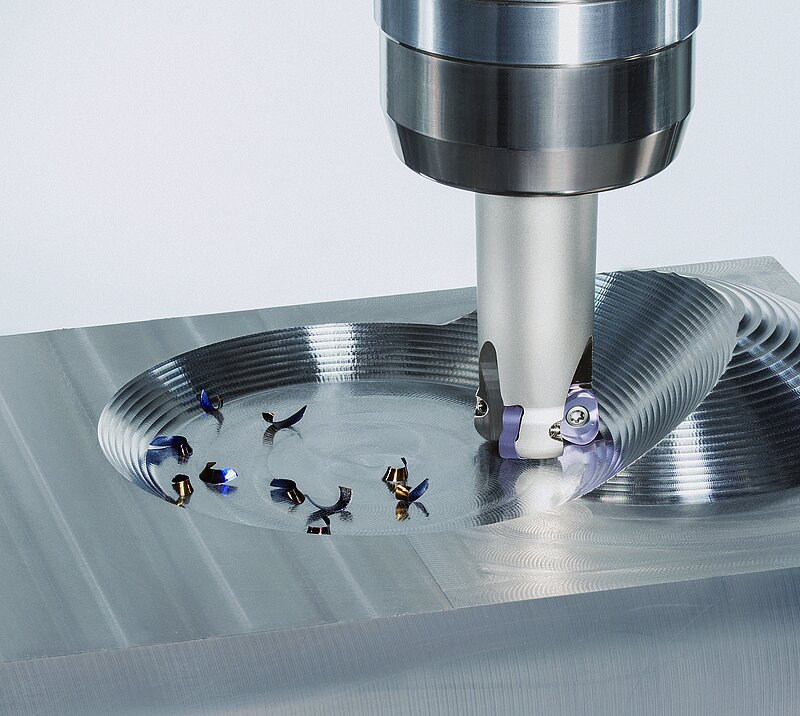

Anyone who wants to stay ahead in machining today needs to be not only fast but also smart. High-performance cutting (HPC) is all about removing as much material as possible from the workpiece in the shortest possible time – or rather, removing it reliably, economically and precisely. Tungaloy-NTK Germany GmbH not only supplies the right ‘teeth’ for this, but also complete tool systems for various milling tasks with high feed rates. Those who rely on Tungaloy are in the fast lane!

In the current difficult economic situation, many manufacturers are considering relocating production abroad in order to reduce costs. But that doesn't have to be the case: with high-performance milling systems, existing machines and expertise can be optimally utilised to increase productivity in your own factory and reduce unit costs in the long term. This means that production remains where the knowledge is – and there is no need to relocate.

Matthias Mergen, Product Manager for Rotary Tools at Tungaloy NTK-Germany: "High-feed milling allows maximum utilisation of machine performance. Although the load on the tools increases, the heat generated is safely dissipated with the chips. This even allows dry machining. A striking feature of our milling systems is the significantly lower spindle load. The cutting forces are directed axially, allowing low-vibration machining with large cutting depths. This is particularly advantageous for older or less powerful machines."

The perfect team for every milling discipline

In the rally of machining, it's not the one who goes full throttle who wins – but the one who perfectly combines driving skills, technology and control. In HPC milling, it's not just speed that counts: the feed per tooth, the cutting depth and the optimal tool strategy are decisive. That's the principle: high-performance cutting is all about removing as much material as possible efficiently and precisely in the shortest possible time – a metal removal rate that is impressive. The downside: the load on the tool increases. No problem – if the tool plays along. And this is exactly where Tungaloy comes into play. Because where others reach their limits, Tungaloy milling cutters really get going. Thanks to sophisticated geometries, robust substrates and intelligent clamping systems, Tungaloy's milling systems deliver top performance across the board – even on demanding terrain and under full load.

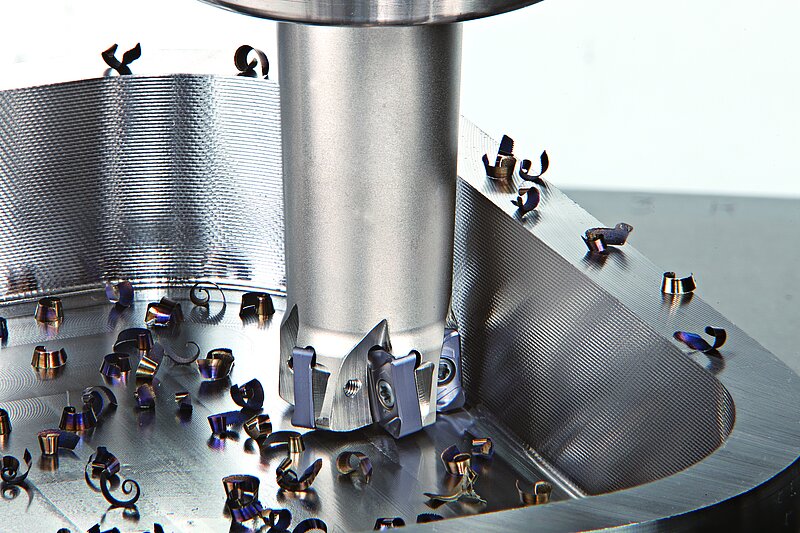

DoFeed – the endurance runner with a refined finish

The classic in the high feed range scores with wiper indexable inserts that don't do things by halves: instead of roughing and then finishing, simply do both in one go. The surface quality? Impressively smooth, well below Ra 1 µm. The sophisticated chip formation and central coolant supply make the DoFeed series the first choice when speed and quality are what counts – often copied, but the performance remains unmatched.

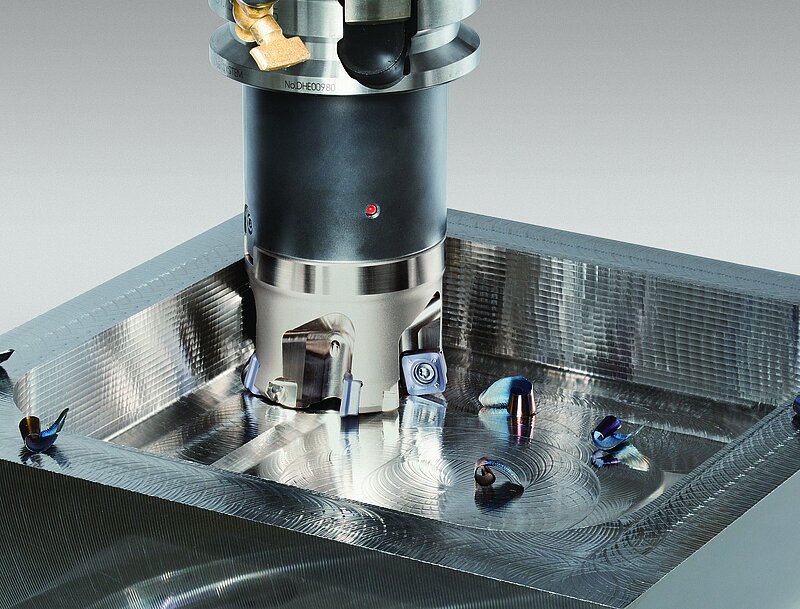

DoFeedQuad – more teeth, more pulling power

Wide pockets, large surfaces? DoFeedQuad can handle anything. The face milling cutter with the ‘dovetail’ not only provides secure hold for indexable inserts, but also ensures perfect chip flow with its wiper edge. Up to 14 mm feed per revolution? That's not milling anymore – that's material removal in low-level flight! The service life is just as impressive as the process stability – a real trump card, especially on older machines with less power.

MillQuadFeed – the octagonal professional

Eight cutting edges on one plate? Every blank is turned into a precision part in no time at all. MillQuadFeed is a real workhorse – with a cutting depth of up to 2.5 mm and a feed rate of 2 mm per tooth. Its particularly smooth running makes it the ideal tool for high performance and low noise. Chips fly, productivity increases – and the milling cutter stays cool.

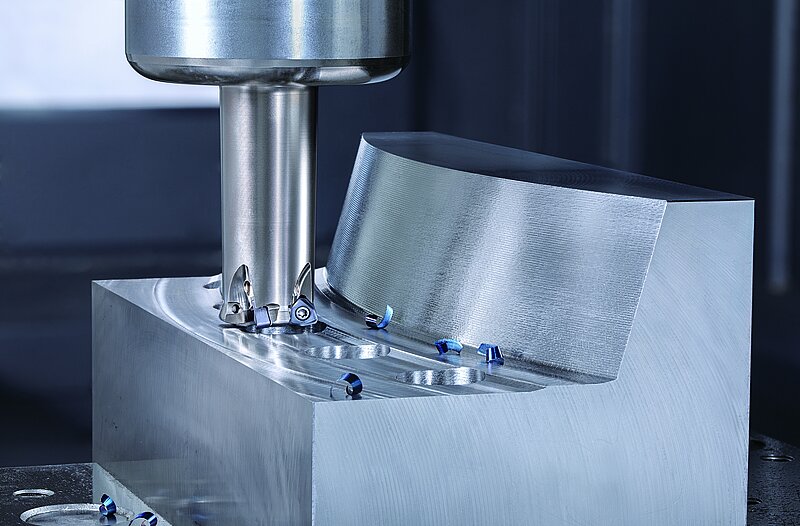

DoTwistBall – cleverly twisted

Round inserts are good. DoTwistBall is better. The spirally twisted WSP inserts show conventional solutions the cold edge. Thanks to their clever design, chips flow away reliably without attacking the screw heads. DoTwistBall is the right solution for milling grooves or pockets or for drilling holes by plunging with helical movements. The distinctive design pays off directly for the user in the form of optimum tool life and outstanding overall performance.

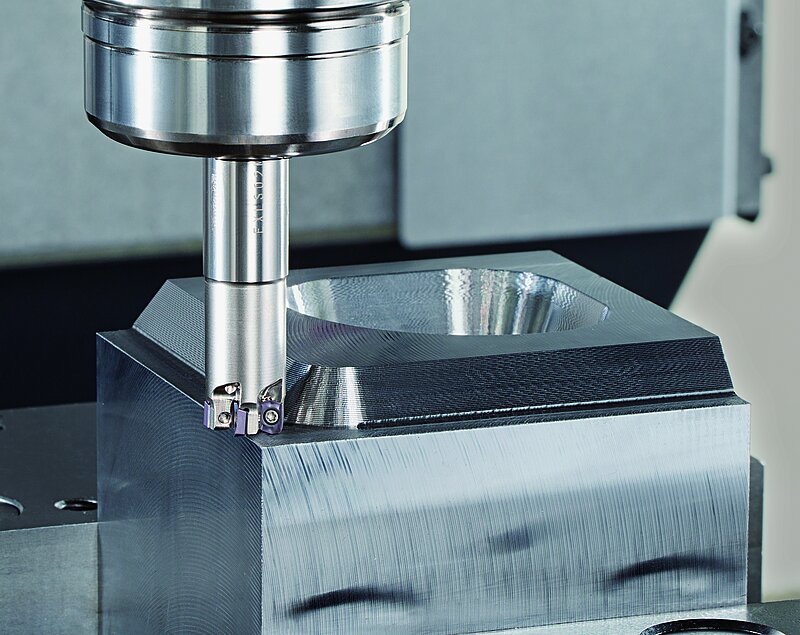

TungForceFeed – the powerful little one

Small but powerful: the TungForceFeed series puts an end to vibrations in small diameters or long overhangs. With diameters starting at 8 mm, the system mills its way unerringly through tight pockets and complex shapes. The stable cutting edges and well-designed chip shape ensure a cool head – even under high pressure. Anyone who thinks that small milling cutters cannot deliver big performance should definitely get to know TungForceFeed.

DoFeed-Tri – six times sharp, three times safe

Six cutting edges on one indexable insert? Even roughing becomes a breeze. The trigonal geometry prevents insert movement during milling and ensures a secure fit. The system really comes into its own when ramping and with long tool overhangs. The reduced entry angle puts an end to chatter marks – and the strong cutting edge delivers what it promises, even at higher speeds.

Tungaloy brings speed to machining

When speed, precision and economy are required, high-feed milling is the way to go. And those who rely on tools from Tungaloy are ahead of the game right from the start. What sets Tungaloy apart from the rest? The perfect combination of material expertise, sophisticated design and genuine process orientation. Whether face milling or pocket milling, ramping, contour milling or grooving: there is the right system for every application – including optimised cutting materials such as AH3225 or AH8015, which make short work of even difficult materials. Whether for single parts or series production, steel, stainless steel, cast iron or superalloys – with Tungaloy, every machining operation is a precision landing in terms of efficiency and quality.

Source | Tungaloy-NTK Germany

![[Translate to English:] InDiamond.world](/fileadmin/_processed_/a/1/csm_InDiamond_Logo_2021_1fb017de30.png)