Improved Cryogenic Machining Processes through Minimum Quantity Lubrication

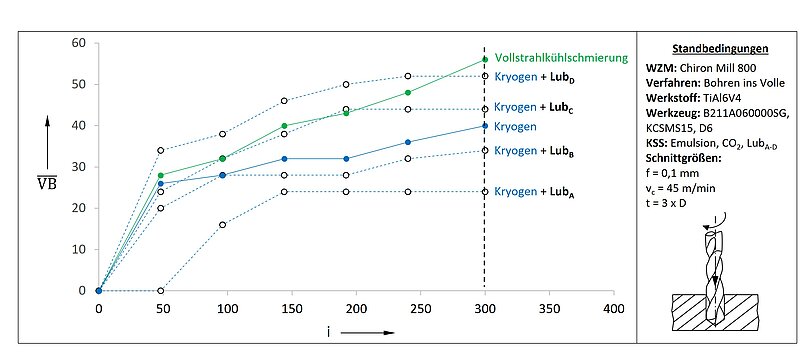

The use of cryogenics for cooling machining processes leads to known positive effects that can be further enhanced by the presence of MQL oils. For example, in drilling titanium components, the combination of cryogenic cooling with MQL results in reduced tool wear, improved surface roughness, and increased dimensional accuracy. However, selecting suitable MQL oils for combined use with cryogenics presents an additional challenge.

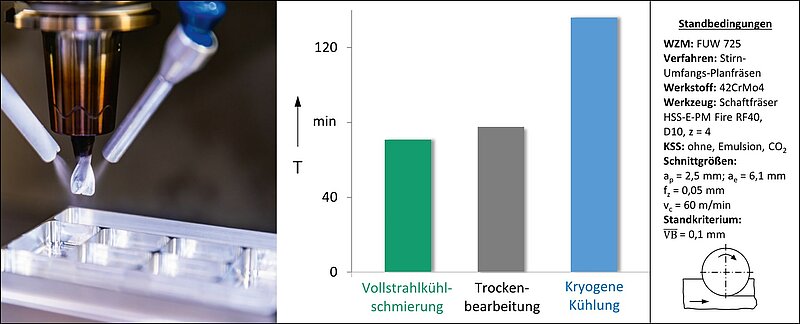

In recent years, extensive research has been conducted on the effects of cryogenic media in machining. It has been shown that the resulting reduction in cutting temperatures, achieved through coolants such as carbon dioxide, significantly impacts tool wear. Technological advancements in cryogenic machining now allow for targeted increases in tool life or significant increases in cutting speed while maintaining tool life, offering substantial time-related cost benefits. Cryogenic cooling can push the boundaries of conventional machining processes, as demonstrated in the machining of steel with HSS tools, where tool life was increased by a factor of 2.4 compared to conventional cooling methods, with a more stable wear progression (see Fig. 1).

In previous research on cryogenic machining, the focus was solely on reducing cutting temperatures through the cooling effect of the cryogen used. Friction-related effects, which also lead to energy conversion, heat generation, and undesirable reaction forces in cryogenic machining, were not closely examined. Against this background, investigations were conducted for the first time at FTZ e. V. in Zwickau on cryogenic machining in the presence of a lubricant based on known minimal quantity lubrication oils. It was examined whether the effects of cryogenic cooling persist with simultaneous supply of an MQL oil and whether further benefits can be achieved through friction reduction.

Framework Conditions

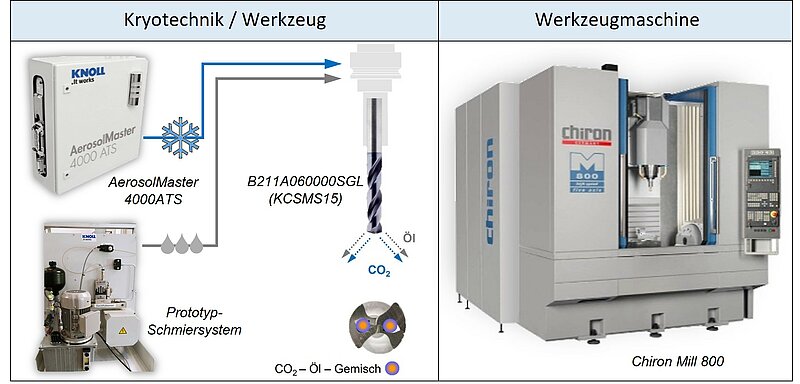

The cutting analyses were carried out using a Kennametal drilling tool on the machining center Chiron Mill 800. This machine tool has been specially converted at FTZ e. V. for internal cryogen delivery, allowing the cryo-cooling system "AerosolMaster" to be directly adapted with a prototype lubrication system from KNOLL Maschinenbau GmbH, as shown in Figure 2. Accordingly, the system allows for combined delivery of carbon dioxide and MQL oil through a single supply line.

![[Translate to English:] InDiamond.world](/fileadmin/_processed_/a/1/csm_InDiamond_Logo_2021_1fb017de30.png)