YG-1 - Absolute precision down to the smallest detail

YG-1 is a South Korean company and global leader specialising in the manufacture of cutting tools such as milling cutters, drills, taps and indexable inserts (solid carbide/HSS). With the opening of a development and production site in Germany in 2018, the focus is now on customer-specific special tools (PCD tools/ISO tools/solid carbide tools).

PRECISION, INNOVATION AND TECHNOLOGICAL EXCELLENCE

The Oberkochen site is the heart of the YG-1 Technology Centre in Germany and is responsible for the development, design and production of special tools that are consistently tailored to customer-specific requirements. Practical experience gained from machine concepts and machining strategies flows directly into tool development – with the aim of creating technical solutions that combine maximum precision, efficiency and cost-effectiveness.

Partnership, trust, reliability and honesty form the basis of all projects. These values shape our daily activities, as does our commitment to excellence in every phase of project planning, implementation and

Innovations are used in a targeted manner to set new standards and exceed customer expectations. The South Korean parent company YG-1 is one of the world's leading manufacturers of cutting tools.

The Technology Centre in Oberkochen sets new standards in the manufacture of high-performance diamond tools and is regarded as the central development platform for innovative tool solutions in the European market. With a highly qualified team and state-of-the-art technology, tools are created that are optimally tailored to individual machining processes and make a decisive contribution to productivity.

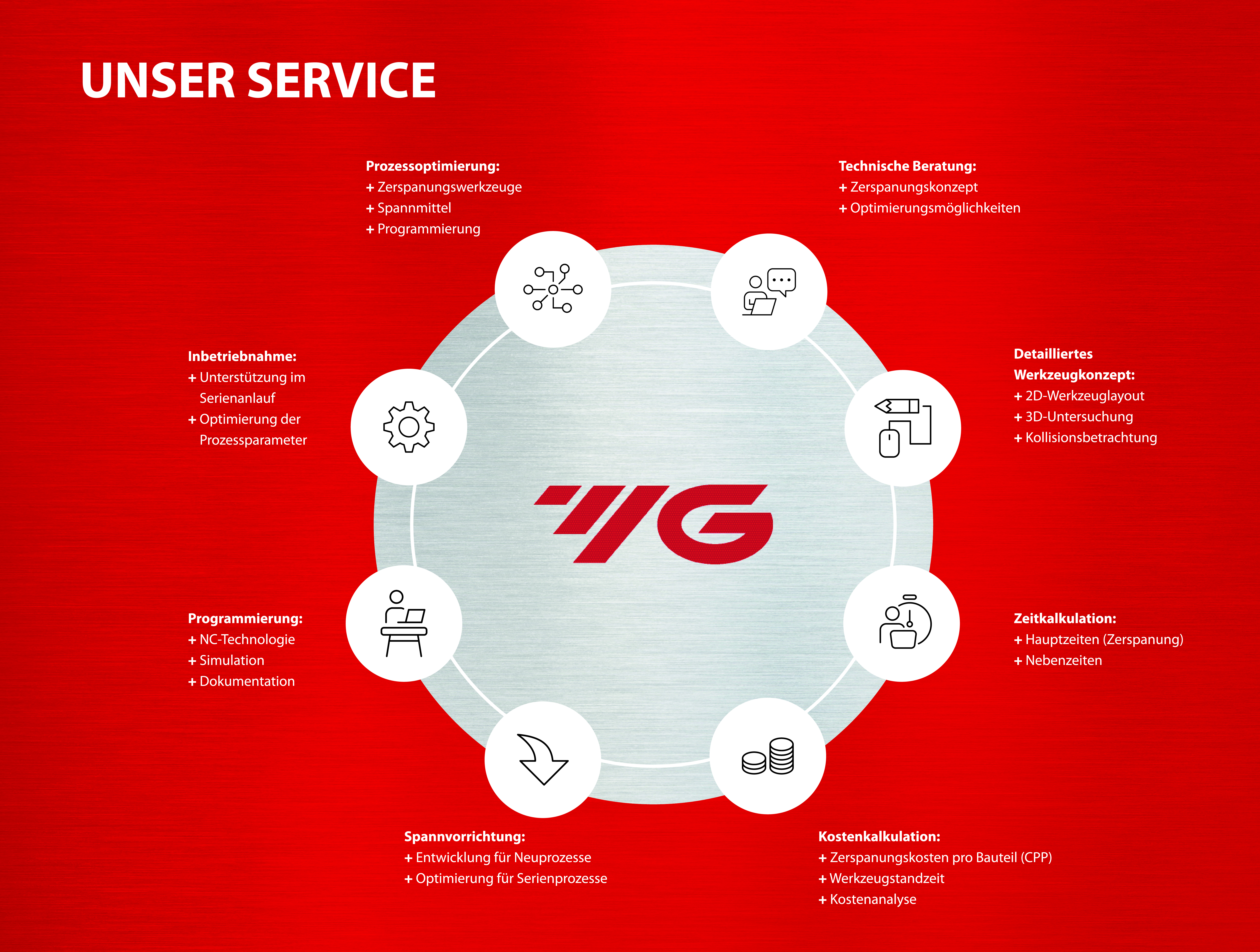

YG-1 SETS NEW STANDARDS AS A FULL-SERVICE PROVIDER

As a full-service provider, YG-1 not only supplies tools – they accompany your project from start to finish. From the initial idea to the finished solution, they support you with expertise, creativity and state-of-the-art technology. Our claim: maximum precision, maximum efficiency and sustainable results.

What YG-1 offers

- Complete tool design: From selecting the right cutting edge to the optimal system tool – tailor-made for your requirements and manufacturing processes.

- Development and production of the right clamping device: Precisely fitting, stable and reliable for a smooth manufacturing process and cycle time-optimised machining by coordinating the tools with the device.

- CNC programmes tailored precisely to your project: turning, milling and machining programmes that are ready for immediate use and make optimum use of your machine capacities.

- Process optimisation and consulting: analysis of existing processes, identification of bottlenecks and concrete optimisation steps.

- Training and support: knowledge building for your team, continuous support and updates on new available technologies.

The YG-1 Technology Centre Germany offers turnkey projects with complete process responsibility. In addition to the design and manufacture of special tools, the range of services also includes the planning, production and process integration of fixtures as well as CNC programming.

This results in tailor-made complete solutions in which the tool, fixture and machining strategy are optimally coordinated. From project planning to on-site commissioning, customers receive all services from a single source.

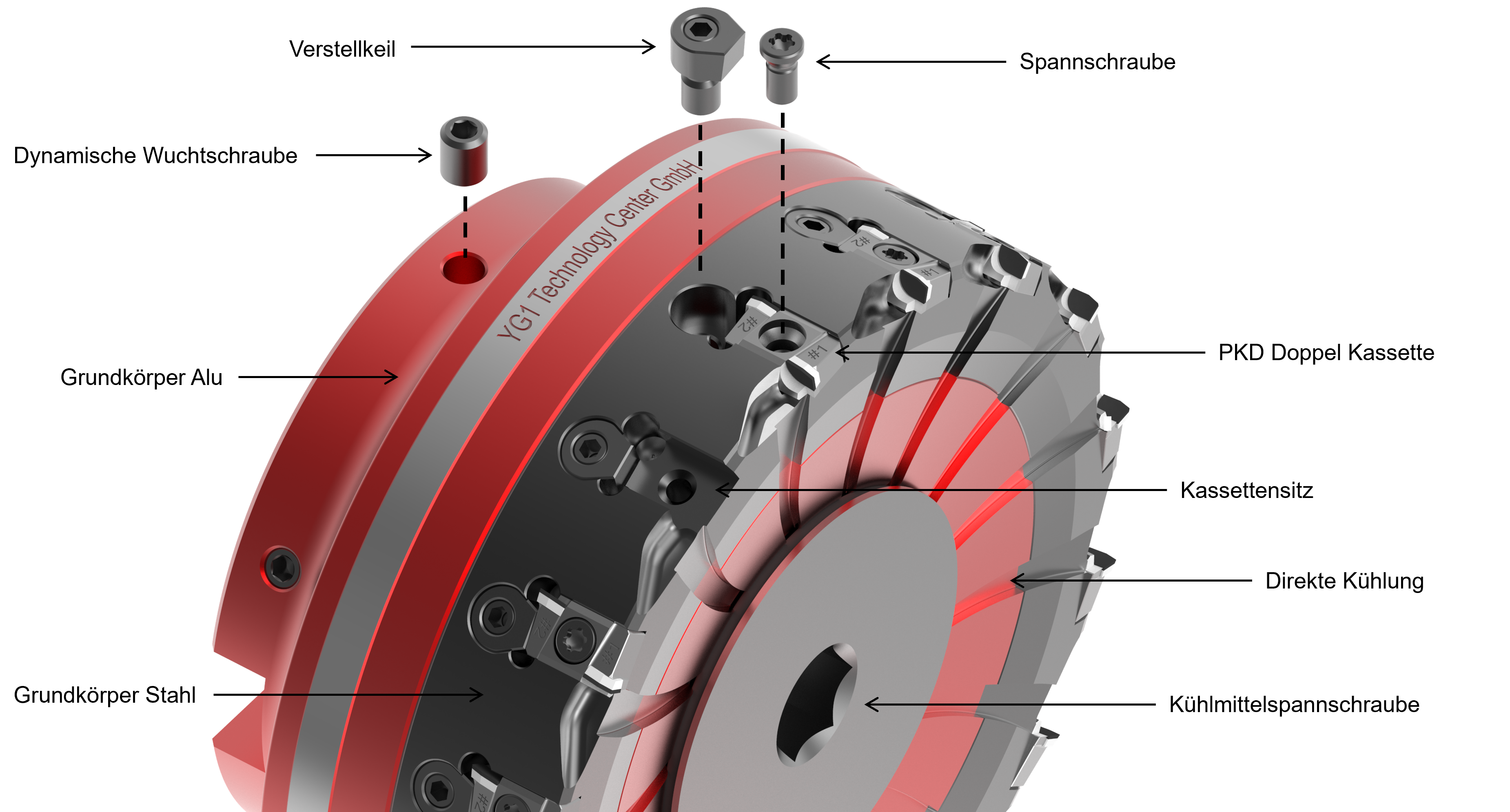

SPEEDMILL DOUBLE FOR PRODUCING THE HIGHEST SURFACE QUALITY

The SpeedMill Double from YG-1 features a unique hybrid design, with an aluminium core that reduces weight and an outer ring made of hardened steel that increases rigidity and wear resistance and provides vibration-damping properties. This combination significantly increases the service life of the tools compared to standard aluminium face mills available on the market. With its high-precision cassette seat and adjustable runout in the μm range, the milling cutter offers exceptional accuracy for finishing operations. It can be adjusted precisely and achieves a runout of up to 2 μm within an adjustment range of 0.15 mm. By using differently equipped PKD cassettes, the tool can be flexibly adapted to different milling requirements (face, wiper, corner or scratch geometries). All cassettes are equipped with 2 insertable cutting edges, thereby increasing the efficiency of the tool and significantly reducing the cost per component.

SPECIAL SOLUTIONS

Together with their customers, they develop tailor-made special solutions for unique challenges. With this innovative strength, they deliver perfect results and solve complex requirements.

YG-1 AEROSPACE

In addition to the Technology Centre in Germany, there is another development centre in Charlotte, USA, which focuses specifically on aerospace. The focus is on the manufacture of high-precision tools for machining composite materials (CFRP/CFK) as well as aluminium and titanium, which are used in the aerospace sector. Specially developed tool geometries combined with diamond coating technologies meet the requirements of their customers. Close cooperation between the locations ensures global standards, fast delivery and consistent quality across all regions. Customers thus benefit from local expertise on site as well as from close, cross-border cooperation with the European and Asian development teams.

Source | YG-1

![[Translate to English:] InDiamond.world](/fileadmin/_processed_/a/1/csm_InDiamond_Logo_2021_1fb017de30.png)