ANCA: 50 years of innovation

ANCA celebrates its 50th anniversary at Grinding Hub 2024 in Stuttgart, showcasing new machines and technologies, the new Tool Room Software Release, and AIMS Connect for networking machines and systems

ANCA, a leading provider of CNC grinding machines and technologies, celebrates its 50th anniversary and unveils a range of innovations at Grinding Hub. Machine premieres, automation, and software solutions take center stage at booth A70 in Hall 7. The core themes of the anniversary presentation focus on maximizing productivity and quality, as well as the diverse value of networking and automation.

Pat Boland, Co-founder of ANCA, states, "For 50 years, ANCA has been contributing to advancements in precision grinding. We look forward to celebrating this with our customers and partners at Grinding Hub. Since innovation is at the core of our brand and ANCA's philosophy, new products and solutions are at the heart of our celebrations. There have been innovation leaps in tool manufacturing in the past, which we aim to continue in the future."

Edmund Boland, ANCA CNC Machines General Manager, adds, "Grinding Hub is the central industry event in this anniversary year. Here, we showcase our latest products and technologies for the production of precision tools and components, developed with a focus on minimal piece costs and maximum performance and quality. As traditional leaders in software expertise, we introduce a new version of our Tool Room software with several creative and effective features, contributing to cycle time optimization."

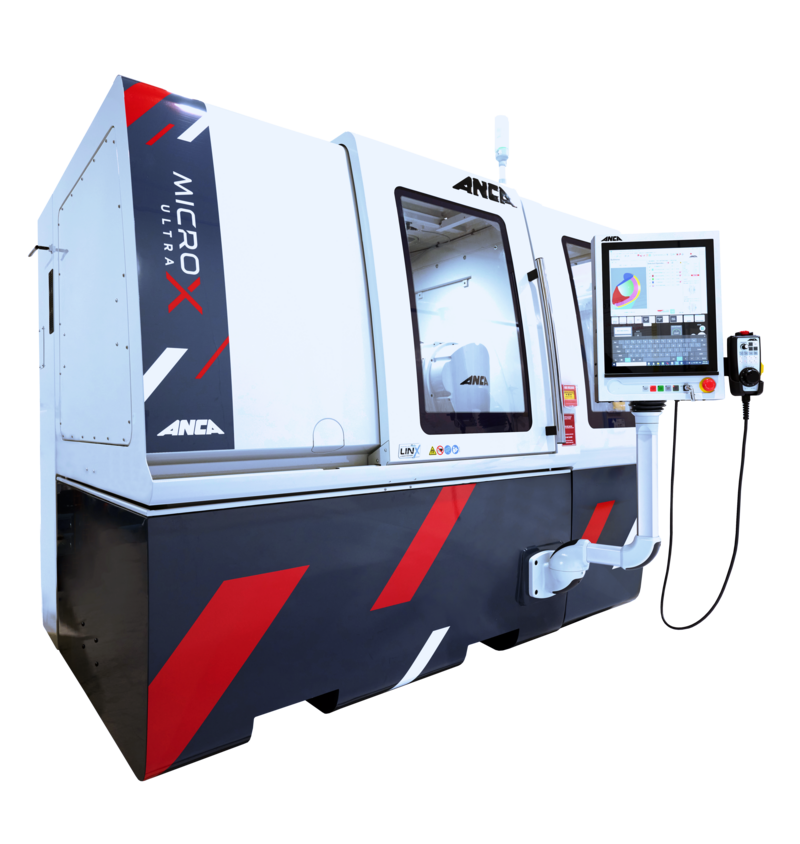

"Tool Room and AIMS truly pave the way for highly productive, autonomous production. With the development of AIMS for connected and automated processes, we contribute to addressing key industry challenges such as labor shortages and designing consistent production processes with intelligent, future-proof solutions. Our ULTRA technology has established itself in the market and now enables the production of micro-tools, regrinding, and small-batch production with MicroX and FX7 ULTRA," concludes Boland.

Practical and Effective: Listening to the Customer

The new EPX-SF Stream-Finishing Machine is being launched at GrindingHub. ANCA's advanced solution for cutting edge preparation and surface finishing offers opportunities for customized and ideal edge rounding for various user industries. ANCA has developed the machine to seamlessly integrate into automated cells.

With its three spindles and eleven axes, as well as intelligent process guidance, the machine was developed by tool experts to optimize media usage while ensuring precise control over edge rounding. The machine is capable of reducing edge roughness to below 100nm and refining edge radii to a few micrometers with controllable K-factor, resulting in nano-smooth surfaces and micron-accurate edges in record time.

The EPX-SF process with pulse rotation serves as an effective protection against surface burrs and edge defects. With adjustable positive and negative angles, the EPX-SF spindle follows the optimal process path, optimizing potential chip flow and reducing surface roughness of the workpiece. Within the ANCA automation system, the EPX-SF seamlessly integrates into production lines and operates autonomously with robot assistance, loading and unloading tools around the clock.

The CPX machine for blank machining is a prime example of how customer feedback can be incorporated into product development. Tool manufacturers worldwide were surveyed and provided their ideal solution for blanks with high material removal rates, application flexibility, and integrated quality control. With features like statistical process control and surface finishes below 0.2Ra, manufacturers using the CPX Linear can achieve high productivity at minimal costs. Some additional application possibilities will be exclusively showcased for the first time at GrindingHub.

ANCA at GrindingHub 2024 in Hall 7, Booth A70

Source: ANCA

![[Translate to English:] InDiamond.world](/fileadmin/_processed_/a/1/csm_InDiamond_Logo_2021_1fb017de30.png)