LUKAS Tungsten Carbide Burrs for Robotic Deburring

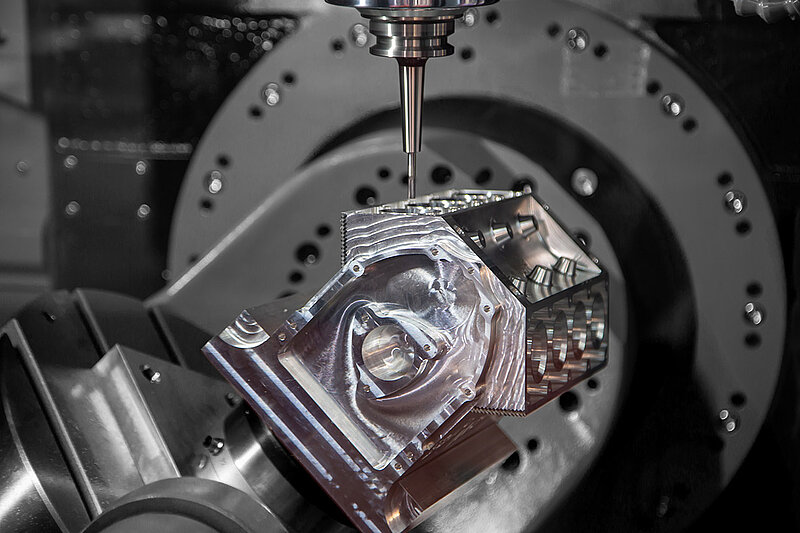

Increase Efficiency and Quality: Deburring with Robots and Innovative LUKAS Tungsten Carbide Burrs – Perfect for Cast Iron, Aluminum, Plastics, and More

Efficient Deburring with Robots: LUKAS-ERZETT Tungsten Carbide Burrs as the Key to Increased Productivity

In modern manufacturing, efficiency plays a crucial role. Time and cost savings paired with the highest precision are essential to remain competitive. One key process step is deburring – a task that requires not only precision but also consistent results.

The solution? Automation with robots. With their high repeatability and reliability, robots can perform both simple and complex deburring tasks efficiently across a wide range of materials. Essential to this are high-performance tools specifically designed for intensive use with robots – such as the tungsten carbide burrs from LUKAS-ERZETT.

These tools help reduce costs, enhance productivity, and optimize product quality and safety. Robotic deburring is more in demand than ever across various industries, including automotive, aerospace, mechanical and plant engineering, tool and mold making, furniture manufacturing, medical technology, and electronics.

Key Benefits of Robotic Deburring

Robotic deburring offers significant advantages, such as efficient resource utilization, high process reliability, and consistently excellent surface and workpiece quality. This is particularly evident when deburring precision components like gears or turbine blades. Additionally, options for multiple machining operations and automatic tool changes contribute to greater efficiency. These benefits apply to virtually all industries and materials, including cast iron, steel, stainless steel, non-ferrous metals like aluminum, plastics, composites, and wood.

While advanced robots tailored to specific materials and workpieces are necessary to achieve desired levels of efficiency, productivity, and quality, the choice of tools is equally critical. LUKAS-ERZETT offers versatile, high-performance tungsten carbide burrs specifically developed for robotic applications.

Innovative Solutions for Robotic Deburring

With over 85 years of expertise in developing tools for milling, grinding, polishing, cutting, drilling, and cleaning, LUKAS-ERZETT GmbH & Co. KG provides innovative and powerful solutions for robotic deburring. Whether for deburring cast parts, non-ferrous metals like aluminum, plastics, or composite materials such as carbon and glass fiber, LUKAS-ERZETT offers tailored tools to meet industry needs.

The company supports customers with a wide range of tungsten carbide burrs, available in various shapes, head diameters, lengths, tooth configurations, and shank diameters. These burrs also come with high-quality coatings that enhance wear resistance, reduce cutting forces, and improve chip removal, ensuring optimal surface quality and process reliability.

For streamlined workflows in automated processes, LUKAS carbide burrs are also available with stop rings for faster and more precise positioning within robotic cells. Additionally, right- or left-hand rotation options allow for tool adaptation based on process requirements, ensuring the best possible results.

Highlighting LUKAS Tungsten Carbide Burrs for Robotics

Here is a selection of LUKAS burrs known for their outstanding performance in robotic applications:

Cast Burr for Cast Materials

- High material removal rates thanks to coarse teeth for rapid operation

- Robust cutting edges prevent chipping and save time

- Faceted tooth design ensures excellent surface finishes

- Steel shank prevents dangerous shaft breakage

Z9 Alu Burr with LightFlow Coating for Aluminum Deburring

- Razor-sharp cutting edges for aluminum deburring

- Up to 5x longer tool life due to LUKAS-LightFlow coating

- Superior chip removal with reduced friction and anti-stick properties

- Faceted tooth design for perfect surface finishes

CarbonCut Series for High-Tech Carbon Processing

- High cutting performance for carbon fiber, CFK, or GFK

- Extremely sharp cutting edges for clean cuts

- Low friction due to thin, smooth, high-performance coatings

- Eliminates fiber tears, protrusions, or delamination

Composite Coarse Burr for Plastic Deburring

- Ideal for deburring, drilling, and sawing plastics

- Long cutting length for versatile use

- High durability reduces tool changes

- Perfectly suited for use with industrial robots

LUKAS Tungsten Carbide Burrs and Robots: A Perfect Match for Modern Manufacturing

Robotic deburring offers immense advantages in the manufacturing industry by ensuring consistent precision, quality, and process reliability while reducing costs. For materials like cast iron, aluminum, plastics, and composites, the value of automated solutions is undeniable.

LUKAS-ERZETT tungsten carbide burrs, designed specifically for robotic systems, maximize the potential of robotic manufacturing processes. These tools feature durability, versatility, and innovative coatings like LightFlow, enabling high material removal rates, extended tool life, and optimal surface results even under demanding conditions.

With solutions like the Cast Burr (for cast materials), Z9 Alu Burr (for aluminum), CarbonCut Series (for composites), and Composite Coarse Burr (for plastics), LUKAS-ERZETT demonstrates its commitment to providing high-quality tools for various industries.

Take the Next Step in Robotic Deburring

Optimize your efficiency, quality, and process reliability with LUKAS tungsten carbide burrs. Whatever the industry or material, LUKAS-ERZETT offers the perfect tool for every challenge. For detailed advice and information about robotic deburring tools, contact the LUKAS-ERZETT team via phone or email. Discover the full range of LUKAS tools at: lukas-erzett.com.

![[Translate to English:] InDiamond.world](/fileadmin/_processed_/a/1/csm_InDiamond_Logo_2021_1fb017de30.png)