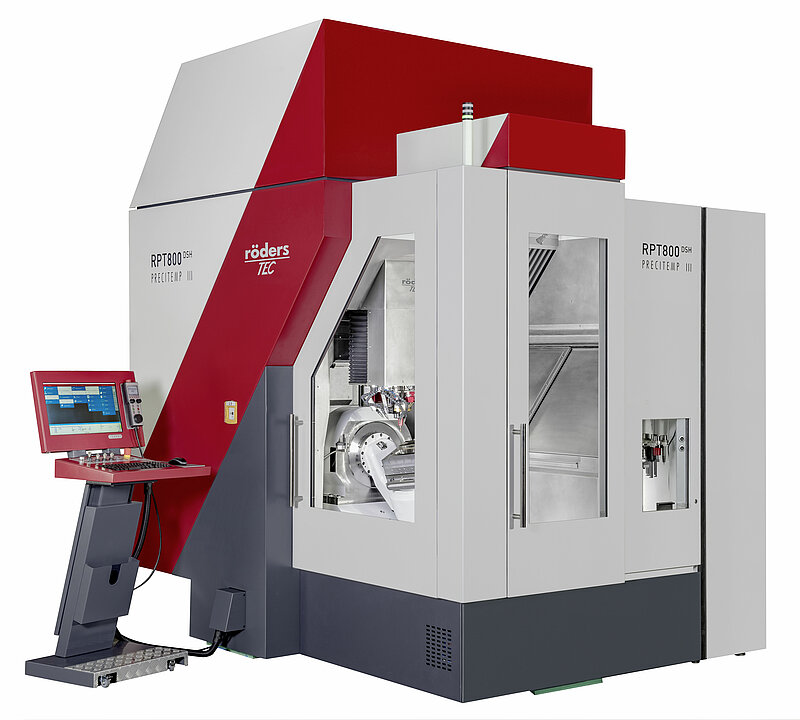

Röders: New RPT Machines Delivering Outstanding Machining Results

There are compelling reasons why Röders GmbH will showcase no fewer than three new RPT machines at EMO. With the groundbreaking developments NANOTOL® and PRECITEMP®, not only are reliably achievable tolerances reduced significantly, but surface quality is also enhanced accordingly. NANOTOL® is a guidance concept designed to ensure exceptionally straight linear axis movement. With the PRECITEMP® technology, RPT machines maintain their precision at 1 μm even under fluctuating workshop temperatures—surpassing the already highly precise RXP machines from Röders by a clear margin.

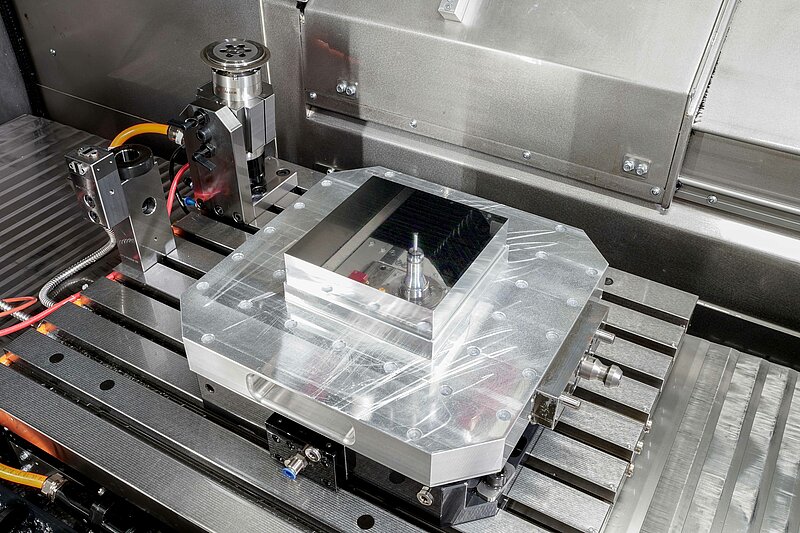

Using a simple aluminum workpiece, the outstanding guiding accuracy becomes evident—not only through mirror-like surfaces, but also through straightness values of < 1 μm.

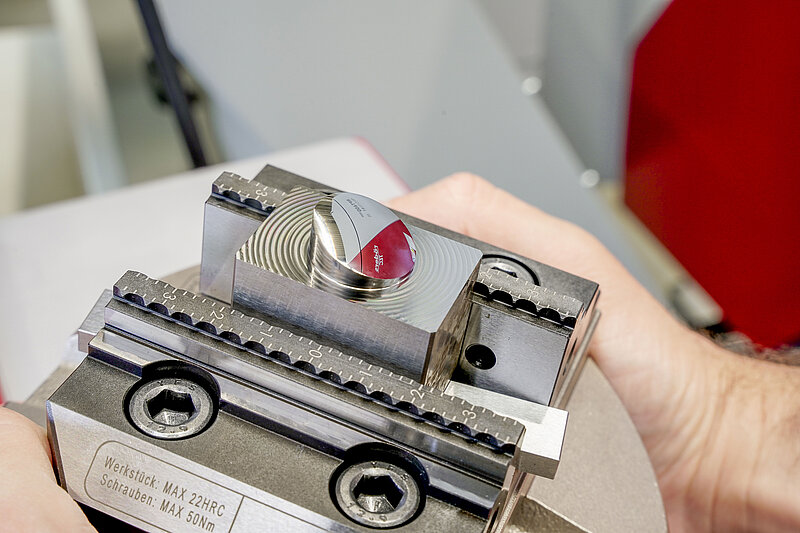

What a machine is truly capable of becomes apparent only with more complex geometries. Thanks to the high path accuracy of the RPT machine, it is now possible to produce optical surfaces significantly faster. For instance, a convex surface with a diameter of 20 mm was manufactured in just 120 minutes. The surface quality of Ra < 10 nm quite literally speaks for itself.

Significant progress has also been made in terms of geometric dimensions. Bore reference dimensions in the range of < 1 μm and cylindricity values of < 0.5 μm can be achieved on the RPT machines. Additional application examples with substantial cost-saving potential will be demonstrated on three machines of the RPT series at the Röders booth, Hall 12, Stand C06.

![[Translate to English:] InDiamond.world](/fileadmin/_processed_/a/1/csm_InDiamond_Logo_2021_1fb017de30.png)