TetraMini-Cut: Precision Grooving and Parting-Off for the Smallest Components – Four Wins: Maximum Performance in Miniature Format

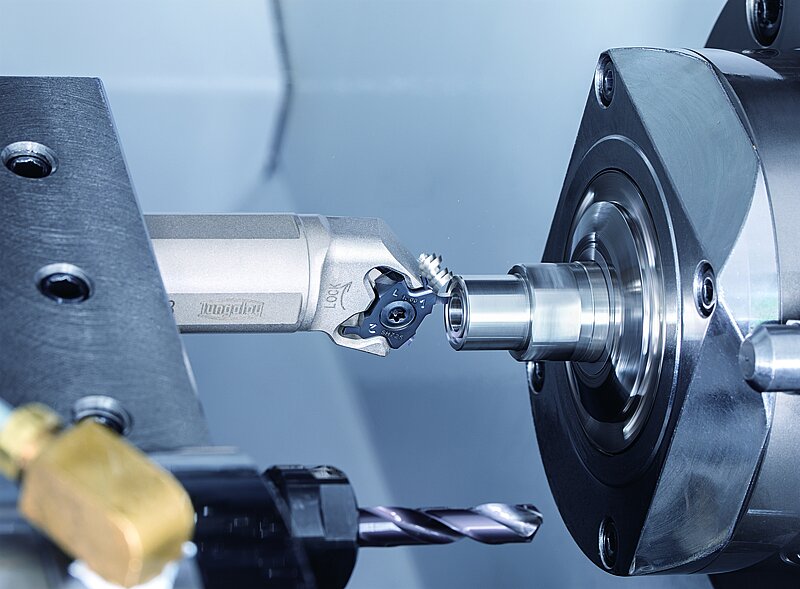

In highly precise grooving and parting-off operations on the smallest components, many indexable inserts quickly reach their limits. Especially when machining shafts with external grooves, fuel injectors, fittings, or medical parts, micrometers decide between success and scrap. For maximum precision and long tool life, Tungaloy-NTK Germany offers a powerful solution: TetraMini-Cut. This high-performance tool with four cutting edges makes grooving and parting off quick and efficient—delivering sharp accuracy and economic operation.

Whether grooving shafts, axial parting of miniature components, or separating the smallest workpieces, TetraMini-Cut from Tungaloy is a true all-rounder in a compact size. With grooving widths up to 3.5 mm and parting operations on diameters up to 6 mm, the tool reliably machines a wide range of materials such as steel, stainless steel, and difficult-to-machine materials. Thanks to the indexable inserts with four usable cutting edges, TetraMini-Cut combines maximum precision with productivity and efficiency. The tool impresses with razor-sharp cutting edge positioning, which not only ensures excellent surface quality but also significantly increases process reliability — even with interrupted cuts or hard-to-machine materials.

Smart interface — the clever clamping system

At the heart of the system is the unique 3-point clamping system: here, the insert is not only precisely positioned but also securely fixed at three points — both form- and force-locked. The result: maximum clamping stiffness, exact repeatability of cutting edge height, and reliable protection of unused edges from damage. In short: a clean job, cut after cut.

Suitable inserts are available for various applications. For example, those aiming to cut precise external grooves use the variant with TCG or TCP chip breakers. For exact threading in the smallest spaces, TCT inserts are the first choice. Even axial parting on miniature diameters is no problem: the TCF18 geometry ensures maximum precision here, too — for a groove outer diameter of only 6 mm.

Two new grades for special demands

Two new carbide grades expand TetraMini-Cut’s application range for specific machining conditions. The AH8005 grade is ideal for high-speed machining in stable environments. A hard, aluminum-rich coating combined with a wear-resistant carbide substrate significantly extends tool life. This grade excels particularly in side cuts and other high-speed applications — bringing speed to the machining process.

Equally powerful is the AH6235 grade, developed specifically for interrupted cuts and tough machining conditions. A nano-coating with a high titanium content effectively suppresses crack propagation at the cutting edge, while a tough substrate ensures maximum tool life and reliability. The effect: more stable processes, fewer tool changes, and noticeably reduced machining costs — even with the most demanding materials.

TetraMini-Cut — Master of the small things

Small parts, high demands — Tungaloy demonstrates with TetraMini-Cut how powerful technology can be in miniature format. Whether precise grooving, clean parting, or demanding thread turning — the inserts consistently deliver top performance. With economical four cutting edges, clever geometries for different applications, and powerful carbide grades, TetraMini-Cut is the ideal choice for grooving and parting operations on small dimensions.

Source: Tungaloy

![[Translate to English:] InDiamond.world](/fileadmin/_processed_/a/1/csm_InDiamond_Logo_2021_1fb017de30.png)