Alku celebrates! Grinding tools "Made in Ländle"

There is a good reason to celebrate at Alku-Diamantwerkzeuge. Exactly five decades ago, in the summer of 1973, the beginnings of the diamond tool manufacturer were laid in the tranquil town of Murr in the Ludwigsburg district by Günther Allmendinger with the support of his wife Reinhilde and co-founder H. Kucher. For the first few years, resin and metal bonded CBN and diamond grinding wheels as well as dressing tools are manufactured in a very confined space. The small business developed rapidly and after only five years the company moved to a larger hall in Marbach to meet the increased demand. Although the company founders parted ways in 1986, as both focused on different production areas, the name Alku remained and Günther and Reinhilde Allmendinger continued to run the company alone. Gradually, the two sons also joined the family business. After 19 years in Marbach, these premises then also became much too cramped and the company moved on to Steinheim, where now already up to 20 employees found space on 800m². Due to the increased number of employees and the steadily growing machinery, another move to Aspach took place in 2013.

Alku-diamond tools GmbH "What counts for us and what we stand for is quality in product and service and identification with customer and task."

From left to right: Holger Allmendinger and Frank Allmendinger

DIAMOND BUSINESS: Alku is a classic family business. You are the commercial manager, your brother is the technical manager, and his wife Judy is the management assistant and responsible for marketing. Was it always your wish to gain a foothold in your father's company?

Frank A.: In my case, it came about during my studies. After completing my training as an industrial clerk, I graduated from a technical college and enthusiastically began studying business administration. After the basic studies, however, the whole thing was too dry, too specialized, and too in-depth for me. I lacked practical relevance and a sense of purpose. So the decision was quickly made to join my parents' company.

And in your case, Holger Allmendinger, was the decision just as clear?

Holger A.: No, I hadn't even toyed with the idea of becoming part of the family business. After my training as a toolmaker, I worked for two years in a mechanical engineering company. After I had completed further training as a mechanical engineering technician, I started working for a large tool dealer in the office. However, this job in the office was not really my element at that time. I was young and dynamic and needed to work out. So, in my youthful recklessness, I decided to join a gym. After about a year, with plenty of experience in self-employment, but quite dissatisfied with the monotonous day-to-day business, I realized that this was not one of my best decisions. During this time, my father called me and asked me if I could imagine supporting and further developing the Alku company. I thought about it only briefly and said yes. I started as an application engineer in the field and in more than three years I acquired extensive knowledge about Alku products and their application possibilities, got to know our customers personally and was thus able to create a solid basis for later developing our tools further and always being available to answer our customers' technical questions. The area of responsibility grew quickly and my work turned out to be very varied. I found it very fulfilling to work things out, organize processes and give different things their course. And it fit much better with my "life" ideas. Since then, 30 years have passed ...

Frank A.: We were both appointed managing directors quite quickly. When we put a computer at our father's workplace in the course of necessary digitalization, it wasn't long before he let us have the office space. He was able to get back out into production and pursue his great passion, just as he had in the early days of the company: Turning, repairing and maintaining machines; seeing where there were problems, getting spare parts - and then getting everything running again. Both our parents were fully committed to Alku throughout their lives. On our father's 65th birthday they handed over the company completely to us, but they were still actively involved. In the meantime our parents visit the company less often, but regularly. They maintain the one or other conversation with employees or customers and are still closely connected to the company.

Alku-Diamantwerkzeuge sees itself as a reliable, long-standing tool supplier for standard and special tools for perfect results in grinding, dressing and polishing. So far, however, you have not made an appearance at the well-known trade fairs. Will this change in the future?

Holger A.: In fact, we were represented at relevant trade shows until 1987. Then, due to the dissolution of the joint management, the trade show business came to a standstill. In 2014, my wife Judy, a trained graphic designer, joined the company. Since she used to organize trade fairs, she suggested that we show a presence at the relevant exhibitions. Unfortunately, something always came up, investments that couldn't be postponed or the lack of manpower for a successful appearance. But now, with the GrindingHub in Stuttgart, the cards have been reshuffled. It would be a home game for us, so to speak. And especially on the occasion of the company's 50th anniversary, it might be a good opportunity to present our products to the general public at one of the next events.

At Alku, two brothers run the business. Are you always in agreement when it comes to decision-making?

Holger A.: Of course there are sometimes different ideas that we then discuss. But in fact our cooperation works very well and we always come to a common denominator. Once decisions have been made, we follow them through together. In the end, it's always about finding solutions in the interests of the company and its successful future, and not about cultivating one's own ego.

There is a lot of movement and uncertainty in the market at the moment. What gives you the most headaches?

Frank A.: In fact, the protectionism that is being practiced around the world worries us a bit. It is increasingly working against globalization. Conditions are changing in many countries, and you don't know exactly where the journey is going. Not to mention Russia and China. In addition, many competencies have already been transferred from Germany to other countries, such as the production of medicines. We have become very dependent on other countries, and I see a great danger in that. For example, I would like to see majority voting rights in the EU, so that the blocking attitude of individual countries would no longer exist.

Holger A.: I would like to see more "competence" in shaping the political framework. I would like to see decisions that are feasible

as well as comprehensible. But many political actors seem to put their own interests or those of their parties more in the foreground than the needs of small and medium-sized businesses.

You have both been managing directors of the company for many years now. What has been the most difficult time for you so far?

Frank A.: In 2017, we found ourselves in an unusual situation: We were completely overwhelmed with orders out of nowhere. To date, we have no explanation for this. Due to this situation, we were no longer able to meet delivery times and fell behind on deliveries. In addition, there were personnel problems that we could not solve overnight. So we were all under enormous pressure and could only react instead of consciously acting.

So on the one hand you had full order books and on the other hand you had this fluctuation, such as employees moving or retiring. How were you able to resolve the situation?

Frank A.: A lot of credit goes to our team, of course, but especially to our young technician at the time, who was to be trained in the office to support my brother's technical area in particular. We had just invested in two new CNC machines. He was involved in the selection and also commissioned them himself.

put them into operation himself. When the situation just didn't get any better, he agreed to work on these machines, i.e. in production. He then spent about a year and a half shooting almost exclusively and did an incredible amount of work with the rest of the small team to get Alku through that time. In 2018, things finally and fortunately eased up again.

What will be your focus over the next few years?

Frank A.: Some of our employees are going into well-deserved retirement in the next few months or years. The task here is to find adequate replacements. In fact, we have already been able to find committed new employees, whom we are currently training for the new field of activity. Here we also allow ourselves the luxury of double staffing, so that important know-how is retained for Alku. This will indeed be our main task in the next years. Beyond that it is

We are now also keen to provide young people with a good and sound training. The initiative came from our new production manager, who approached us with high motivation to train. The content of the apprenticeships focuses on machine and plant operation.

Holger A.: We want to continue to grow healthily. Although we have been able to increase our sales in recent years through improved efficiency and internal restructuring alone, sustainable growth is achieved primarily through expert sales staff, who are not easy to find, especially in this day and age. And our quality standard is to send only qualified technicians into the field. Right now, we are very grateful for our highly motivated, dedicated team. We can't remember ever being able to count on such a good team.

They produce diamond and CBN grinding wheels in resin, metal and metal hybrid bonds. The market is highly competitive. How do you stand out from the competition?

Holger A.: We focus 100 percent on each customer and meet their most diverse requirements. We work in an extremely solution-oriented manner for the benefit of the customer, and you can feel this attitude. If there are any difficulties, the technician is on site and a solution is worked out together. And always the best solution! That is our company motto. In addition, our customers quickly reach the right contact person, so that we can help immediately and competently. If an order should be very urgent, we check the feasibility on the basis of the capacities. We work with high efficiency and flexibility. Our customers appreciate this very much and are always happy to recommend us for this reason.

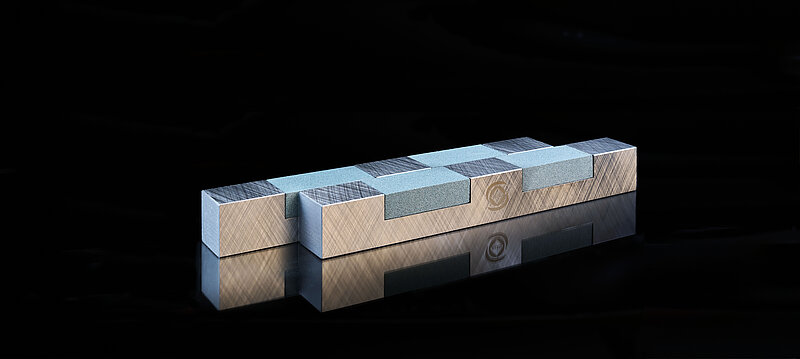

On your redesigned website, you offer the Alku dressing shaft and the Alku dressing block. What is the benefit for the customer?

Holger A.: For a few years now, we have been offering these two first-class products developed by us. They are special tools for the maintenance of our core products. The Alku dressing block was designed for fast and precise dressing of diamond and CBN grinding wheels in resin bond on surface grinding machines. The ALku dressing shaft, on the other hand, is used for dressing these tools on cylindrical and CNC tool grinding machines. As a result, our customer achieves excellent flatness and cylindricity of the coating on his wheel. And another advantage is that the grinding wheel can be used again immediately after dressing. This saves our customer an enormous amount of time and effort, allowing him to work much more effi ciently.

The high demand speaks for itself.

Which market has developed positively for Alku in recent years?

Frank A.: Our main focus is still on mechanical engineering and the tool industry. In addition, the optics sector, especially precision optics, has developed very well. This requires special tools that not everyone manufactures. Over the past 30 years, we have been able to further deepen this competence in addition to our core business.

deepened. This industry in particular has always remained stable, even in economically worse times.

E-mobility, digitalization and automation - these are just some of the trends that certainly also challenge Alku. How do you see the future development of Alku's business areas?

Holger A.: There are now some machining processes that compete with grinding, such as EDM or hard turning. Nevertheless, this has not affected the grinding industry. The new "trends" will also require materials that have to be ground. Many materials can only be processed perfectly by grinding in order to meet the increased demands. We therefore continue to rely on our now 50 years of competence and experience, but are always alert to develop new manufacturing methods or products for us.

Corporate values are the central guidelines that determine how your team works together and interacts with each other, both internally and externally. Which values does ALKU stand for?

Frank A.: We want to be perceived by our customers and partners as reliable, trustworthy solution providers. We live partnership. That's why honesty, transparency and commitment are at the top of our scale of values. This starts with us internally and can only be lived with the corresponding inner attitude of the entire team. We encourage our employees so that we can challenge them to achieve the goal of the highest product and service quality at the same time. This is far more than smooth project management and, as a result, cooperation that is fun!

After graduating from high school, Frank Allmendinger trained as an industrial clerk at a large automotive supplier. He then went on to obtain

to start a degree in manufacturing business administration. After completing his basic studies, Frank then moved to his parents' company to learn the knowledge of diamond tool production from the ground up. He likes to use his fondness for numbers and calculations for the benefit of the company and always keeps an eye on Alku's key figures. Besides these business and commercial tasks, his activities are also in the technical order processing and production engineering. Together with his brother Holger, he has been managing the company since 1996, and the two complement each other excellently by sharing the various management responsibilities in a sensible way. Currently, Frank is very proud of his dedicated team in the company, which in turn motivates him very strongly. He can relax best when he spends his summer vacation in Tuscany with his wife. His two grown-up children still join him from time to time. While his daughter has completed her studies in medical technology, his son, a trained industrial mechanic, will soon begin further training to become a mechanical engineer. With these prerequisites, it would of course be quite possible for the two of them to join the family business at some point. But, he says, he prefers to give both children full freedom to choose their careers. Because only if you approach company management with joy and enthusiasm will you be able to master the challenges of the future.VITA FRANK ALLMENDINGER

Holger Allmendinger's motto in life is "Always see the positive side of life", because life is always about looking for solutions and it would never be productive to deal with things that you can't change anyway. After his apprenticeship as a toolmaker at a gear and transmission manufacturer, he worked for two and a half years in production and assembly at a company for special machine construction. He then attended mechanical engineering technology school for two years - the ideal prerequisite for gaining a foothold in his parents' company. However, this was not so clear from the beginning. But since his office work at a tool dealer did not challenge him much, he gladly came to Alku via a small detour - first to the sales department. There he was able to learn a lot about grinding and the demands on Alku grinding tools. The relationship with his parents and brother has always been excellent, so even working together in the company has only strengthened the family togetherness. Since 2014, his wife Judy has now also joined the permanent Alku team. As assistant to the management, she organizes all areas of the core business and is also responsible for marketing as a graphic designer. Holger Allmendinger takes care of the day-to-day business of processing

processing of quotations. He and his wife Judy have now also invested a great deal of effort in updating the content and appearance of the website to reflect the company's 50th anniversary. But in the main he is responsible for product development, sales and EDP. His tasks are therefore varied, and that is what makes the whole thing interesting. He can relax wonderfully when he gets to know the country and its people on different continents together with his wife. He would love to spend three months on the road to immerse himself in foreign cultures and readjust his own perspective.VITA HOLGER ALLMENDINGER

![[Translate to English:] InDiamond.world](/fileadmin/_processed_/a/1/csm_InDiamond_Logo_2021_1fb017de30.png)