Brilliant solutions for perfect surfaces

The abbreviated company name, which is still known today, was created from the initials of the company founders Josten and Kettenbaum. In 1940, Kettenbaum began to develop welding equipment and thus laid the foundation for the renowned company in the field of welding technology that is still known beyond the borders of Germany today. Tool manufacturing companies, especially the mold making industry, were also interested in further innovative solutions. Therefore, the commitment of the company founders grew to offer complementary developments in the field of surface finishing. Since 2010, Udo Fielenbach has now been the owner and managing director of the Bergisch Gladbach-based company. His sons Marc-Andre, Max and Alexander now complete the whole to a reliable, modern family business. On the one hand, they hold on to the traditional values and standards of the company's founders, on the other hand, Joke convinces with advanced in-house developments and a high sense of regional responsibility. Good prerequisites, therefore, to successfully tackle the next decades of Joke's existence. In this interview, Alexander Fielenbach explains what the market will demand in the future and what answers the European market leader for surface finishing has to it.

DIAMOND BUSINESS: Mr. Fielenbach, you have been at your father's side for about three years. What is your job now and in which areas will you take on responsibility?

Alexander Fielenbach: My father and I form a team in the management. This gives me the chance to benefit from his experience every day and to learn alongside him. Nevertheless, we also complement each other and have already worked well together over the last 3 years, so that everyone contributes their strengths.

What does Joke stand for?

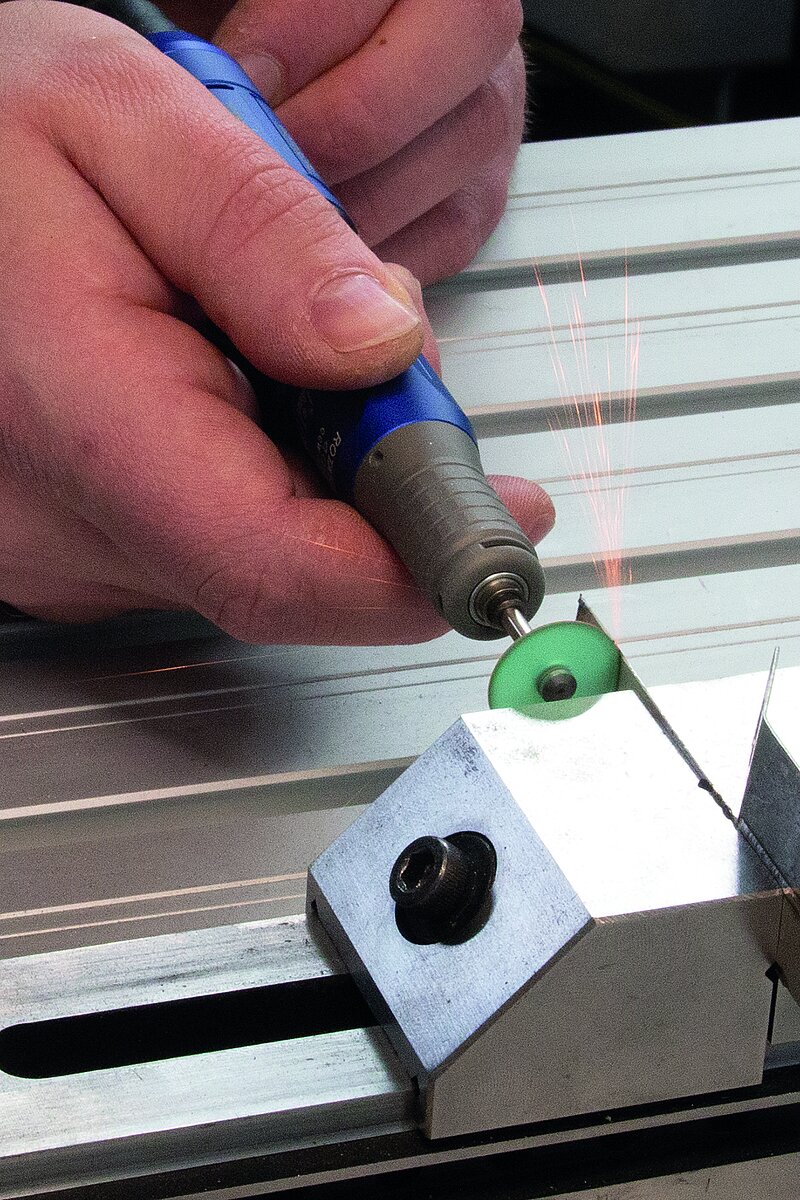

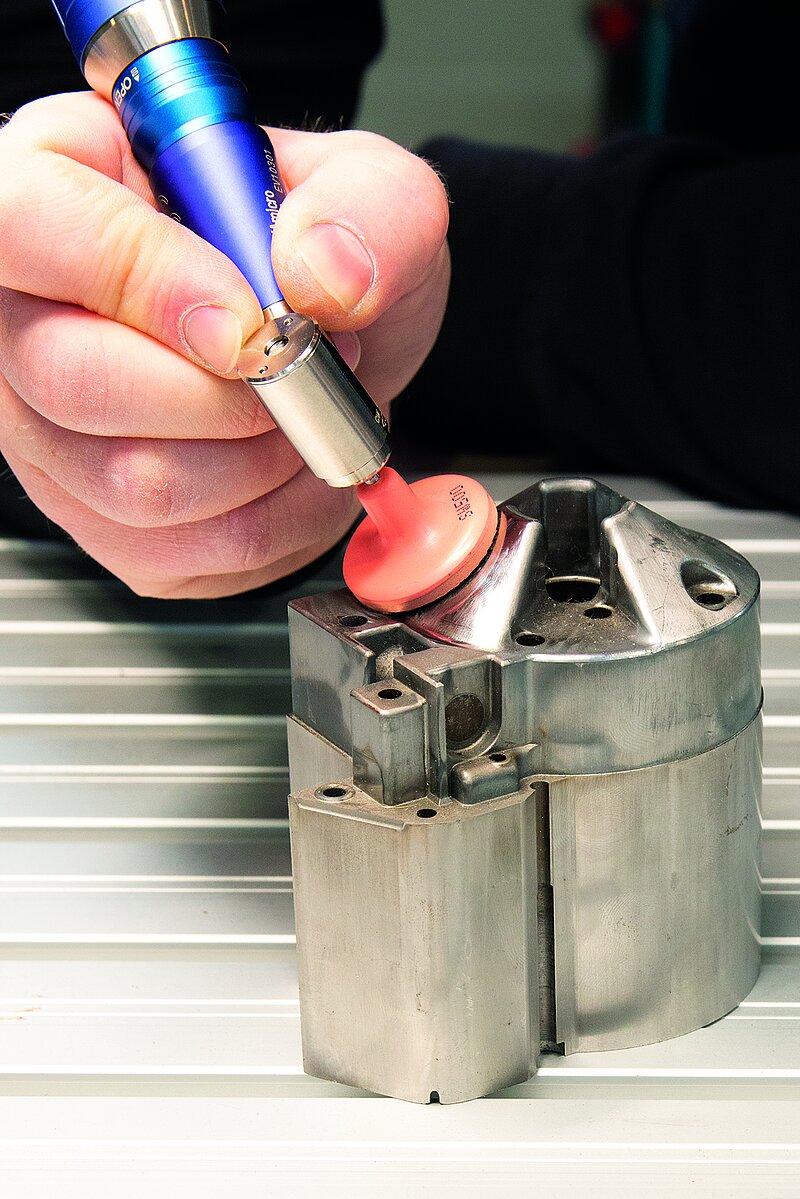

Whenever it comes to grinding, lapping, milling, polishing, deburring, welding or even cleaning: you will find our core competencies in all types of surface finishing. As a leading specialist in the field of surface technology, we offer around 20,700 products and have a first-class online store. Customers particularly appreciate our extensive range of products for the metalworking and tooling industry, from basic surface finishing equipment to additional equipment for highly specialized applications, such as in medical technology or the jewelry trade. Our profession is surface machining at the highest level, which can be perfected by our products. We not only guarantee the highest quality, but also offer competent advice and comprehensive service. A large part of our product range is available immediately and is usually in our customers' workshops the day after the order is placed.

What else do your customers appreciate?

In particular, we strive to be as innovative as possible and are constantly expanding our portfolio. Starting with our own production of diamond polishing pastes to individually manufactured consumables and especially through the new development of application systems in-house, even when only small quantities are involved. The associated major technical progress gives us a unique selling point on the market. For example, we have already won the innovation award here from the region for a development project.

What project was that for specifically?

"With the ENESKApostprocess, we have developed a post-processing system for safe handling with 3D printed workpieces. In an enclosed workspace equipped with a powerful extraction system, the workpieces can be fully processed with the help of our pneumatic and electric tools. Until now, users have sometimes had to wear full-body protective suits for these steps to protect themselves from the dangerous dust particles. However, these offer no protection against the additional risk of deflagration. In our ENESKApostprocess, the machining process can be carried out safely."

What has changed in the course of Joke history?

Originally, we were a pure trading company. However, we were still perceived as a manufacturer by our customers in many cases. This outward impression seems to have been created because we marketed many of our products under our Joke label. Fortunately, we have had our own development department for several years now, which is able to produce everything from assembly to completion completely as genuine in-house production. Partly we also make use of the know-how of our sister company Joke-mechanixs GmbH. That is why we can also advertise with the quality label "made in Germany". Who can do that nowadays? Based on the needs of the market, we can develop many new products. The direct contact to the customer by means of our field service crew contributes an elementary part to this. Particularly when it comes to special challenges, the product manager travels to the customer's plant if necessary, examines the workpiece to be produced, and together they work out a solution for it. This is part of our company philosophy.

Your portfolio also includes many diamond products. Do you manufacture these yourself?

In the field of diamond and CBN tools, we cooperate with renowned partner companies whose products stand for quality and reliability in order to guarantee optimum work results. Polishing pastes and lapping suspensions with diamond components are largely manufactured by us. Which industries do you serve then? We serve many industries with our know-how, such as the tool and die industry, the automotive industry, the medical sector, etc.. The aerospace sector is also a very big topic for us, which is becoming more and more important. In addition, 3D printing is an area that will play a central role in the future. This is where we can successfully start with our products in post-processing. Ultimately, we are the complete supplier for surface finishing. We offer the largest product range on the market.

You score points with your customers with a broad-based sales force. How is this organized?

We have seven sales representatives who are exclusively on the road in Germany and Austria. In addition, we have export partners in many European countries who are represented by their own sales representatives. They all have a technical background, are regionally close to the customer and can offer technical solutions. For unusual, special applications, our in-house product management team is also always available to provide advice. In addition, we have six presentation vehicles in operation. This means that we have welding mobiles in which fully functional laser welding equipment can be presented in a completely realistic way in full function at a real workplace and a real workpiece. Even the "postprocess" post-processing station just mentioned can be presented on a demo vehicle on site. This system can then be presented live at the customer's premises. In addition to the field service, we also have, for example, polishing or welding trainers who become active at the customer's request and demonstrate Joke products in their best application. Here, too, we have taken on a certain pioneering role in the market.

To what extent have these demo or presentation vehicles proved their worth?

Ultimately, these are small mobile workshops. Customers can try out the equipment on site and, if necessary, also process their own workpieces. Particularly when we can present our large-scale postprocessing system to our customers on the company premises in a demo vehicle, we save them the trouble of traveling, as such large systems would normally have to be presented stationarily in a customer center. The decision-making process is accelerated, because users as well as managers and decision-makers can simultaneously and jointly put the system through its paces and convince themselves of its advantages. However, there is still the possibility of holding training courses or presenting products here in our "Jokeneum" at the Bergisch Gladbach site.

What opportunities do you see now with Joke for the next few years, respectively, what will the market demand in the future?

The biggest challenge we face is in market development. We have a very high market share, but the market size is limited and will in all probability shrink rather than grow. On the one hand, this is mainly due to technical progress, especially when it comes to the finishing of workpieces or castings, for example, and on the other hand the shortage of skilled workers plays a major role. At the same time, however, there are opportunities for new markets. We therefore see market growth above all in 3D printing and automation. In addition, we score points with our core competencies, which are size, the most extensive range on the market, top quality, and consulting services in the form of technical expertise.

It's been over ten years since your father acquired the company. What was the motivation for this and what has changed since then?

In 1994, he had already founded his first own company. He offered engineering services for the automotive industry. He himself had devoted himself particularly to the commercial side. He had started with six employees and then in 2009 the company with 450 employees was sold. Originally, his plan was to retire from work completely. After a few months, however, he wanted to take on new challenges again, and by a roundabout route he came to the Joke Group. The company was restructured and reorganized in many areas. In the meantime, not only has the number of employees tripled, but sales have also increased significantly.Today, we are experiencing an extremely economically healthy and stable company. Our aim is to create a working environment in which employees feel comfortable and can work in a relatively self-determined and responsible manner. The length of service with the company is above average, and fluctuation is gratifyingly low. We are very proud of the fact that we have succeeded with our employees in becoming the European market leader in the field of surface finishing. The reputation that Joke already had was excellent. The foundation was thus laid and our tasks consisted of creating better structures again in certain areas.

Alexander Fielenbach has always been a fan of motorsports. After completing technical secondary school and attending a commercial college, he initially opted for a classic apprenticeship as an industrial clerk in a large corporation in order to gain practical experience and to gain a comprehensive insight into all the different departments of the corporation. As an enthusiastic hobby racer and with a passion for racing, he began working for a 5-man company dedicated to racing after completing his training. On the one hand, this allowed him to reconcile his passion and his professional responsibilities well, and on the other hand, he got to know opposing structures in this micro-enterprise, which broadened his horizons of experience. After six years, he felt the need to switch to his father's company, as he wanted to take on new challenges and tasks. He now gladly accompanies his father in the daily business and they consult and decide elementary things together. In many respects he is also impressed by the approach of his father, who can now look back on many years of company management and successes in his life. As in racing, the 31-year-old does not see himself as a lone fighter, but is glad that he can rally a whole team behind him at Joke. It is important to him that many decisions can be made autonomously in the individual departments and that responsibilities are clearly defined.

responsibilities are clearly defined. Alexander is particularly fascinated by his father's "gut feeling," who has always been right on the money in recent years with his intuitive decisions. This has now also earned him an invitation from the German President, as he was able to convert machines at Joke-mechanix GmbH within a very short time so that millions of infection aprons could be produced during the Corona pandemic. For Alexander Fielenbach, success is the result of commitment and passion and, as in racing, it is important to him to always follow his own individual path.VITA ALEXANDER FIELENBACH

![[Translate to English:] InDiamond.world](/fileadmin/_processed_/a/1/csm_InDiamond_Logo_2021_1fb017de30.png)