Lehmann Präzisionswerkzeuge GmbH: From a garage business to an internationally successful medium-sized company

Actually, the company Lehmann Präzisionswerkzeuge could be described as a literal "hidden champion". If you drive through the tranquil village of Kleinförstchen in the center of the Upper Lusatian district of Bautzen, you will see idyllic single-family houses lined up along an untraveled country road. In the middle of this dreamy settlement stands a tool company, which at first hardly differs in size from the silhouette of the rest of the village. Only a few steps inside the company are enough to experience that the company building and the adjacent, renovated and converted former manor house offer space for more than 100 employees. Yet the village itself has only about 75 inhabitants. However, "hidden champion" is also synonymous with growth companies in the FRG. This condition is also fulfilled. What began as a "garage company" shortly after the fall of the Berlin Wall in 1991 has, over the years, grown into an innovative tool manufacturer. In addition to milling, reaming and carbide tools, the Saxon company is also known for its PCD tools and is in no way inferior to the global players on the market. "On the contrary," self-made entrepreneur Lehmann states unequivocally: "My team and I manufacture at the highest level and attach great importance to precision and the best quality." At the same time, we are maximally flexible with our employee size and our customers are the best teachers."

David versus Golliath or who has the better cards in the end?

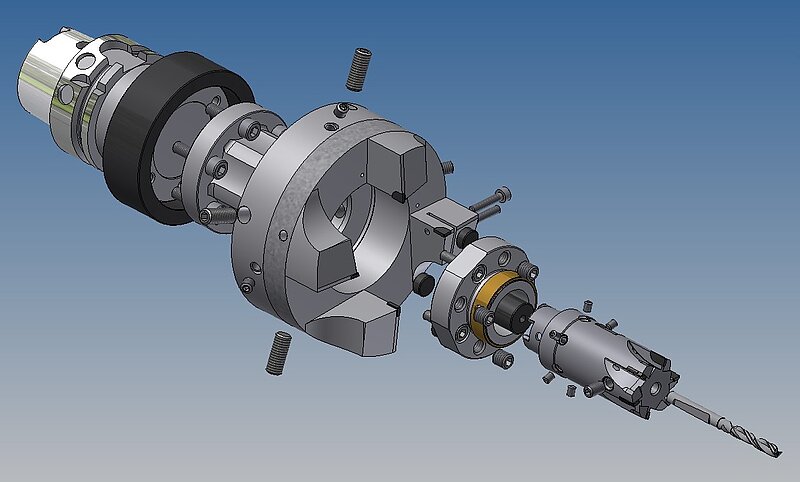

Roland Lehmann, a trained industrial mechanic, initially started his own business with a small grinding shop. Initially, he also only took orders for the polygraphic industry. Gradually, other tools for various applications were added. He was then able to outsource some of the work, but often had to contend with unattractive delivery times, and in the end he was not satisfied with the quality either. He therefore decided to manufacture the PCD tools in-house, and this turned out to be a lengthy process until the first tools could actually be delivered in the desired quality. It was no use just buying an EDM machine. According to Lehmann, it's about the entire value chain that has to be mapped, i.e. the entire engineering. "Many things, such as soldering, lasering, grinding, the right dimensions - all of these things have to be learned, and ultimately you have to develop a feel for everything. Nobody shows you that. There are no courses or training for that," says the Saxon entrepreneur with a frown. Initially, he had to prove himself against the market leader in the industry.

As a small medium-sized company, however, he was able to score points with speed and flexibility. This starts with project planning and extends to the optimization of the tool. And he adds that there is hardly a project in which it is not possible to optimize, such as geometry. Of course, you need the necessary passion for this, but you also have to love the challenges. With a smile, he adds that he has employees who only leave the plant inspired when they are introduced to new tasks and challenges, develop solutions for them and grow from them. This fills them with pride and, of course, helps the company to move forward.

Customers as the best teachers

The company has benefited and grown from its very critical customers. A few years ago, Lehmann recalls, one of them was very meticulous, almost over-correct with the workmanship, and one day he had complained about a tool that had been delivered under a µ tolerance deviation. In the meantime, his employees had already developed a defensive attitude towards these "meticulous" customers and virtually made arcs around these orders. They were marked and it was particularly important to work precisely for this customer. "Actually the wrong way of thinking," says Lehmann. Without further ado, he decided to manufacture all of his customers' future orders at this level. His employees were initially reluctant to do so, because the complaints were really only coming "from one corner. Today, no one complains about his decision at the time, and the increased order volume proves the entrepreneur right.

Meanwhile, Lehmann is convinced that this one customer has been an important milestone for the company in Göda. Many users now order tools without knowing a price for them. Of course, he says, he makes offers and sends order confirmations. But customers have full confidence and know that we manufacture our tools to a high standard. The only thing that is more important, he says, is the delivery date.

Proud of his crew in the background

Roland Lehmann seems to have rallied his employees behind him. He says he is aware that his Lehmann team makes a significant contribution to the company's success. He involves them in many decisions, for example when it comes to purchasing new machines. He sees himself as the "driving force" for the company, he initiates new projects and is on the ball when it comes to innovative further developments for Lehmann precision tools. As a rule, he can no longer operate his machines and systems, but he knows what the machines can do and is also regularly present at training sessions for the machines. However, he also says that he always has an open ear for the private concerns of his employees, that his door is always open and that he is also available as an advisor if necessary. He is proud of his team and is also always eager to bring many young people into training. Be it as part of a dual study program or as an apprenticeship as an industrial mechanic. He sees very well that the apprentice workshop would lay the foundation for the future of the company and that is why sound training is enormously important to him. Unfortunately, he says somewhat thoughtfully, the young workers are increasingly absent. Otherwise, he always had three to four trainees per year. For the fall of 2022, he has only one apprentice in sight, but he has not yet signed his contract. Unfortunately, the entire industry is struggling with this, Lehmann emphasizes. Politicians must also set the course here and introduce young people more to vocational training. He emphasizes that as a student in a certain grade, he himself had to complete an internship in a company every Friday. With these different internship experiences, it would be much easier for young people to make decisions for life and they would be clearer in their career choices. His eldest son has now also been part of the family business for a year and a half. After completing his apprenticeship as a tool mechanic with a well-known writing instrument manufacturer, he worked as a journeyman for several more months, and now he is learning toolmaking in the company from the ground up and is currently assigned to EDM in the PCD department. "Yesterday," comments Robert Lehmann happily, "my son approached me and asked to be allowed to take the trainee's license. I think that's a great thing, if he identifies with the company and takes the initiative himself." Roland Lehmann is also grateful for his wife at his side, who has accompanied his independence from the beginning and is thus an important support for the tool company. In addition to her commercial activities, she is always an excellent advisor when it comes to operational decisions.

Rittergut as additional company headquarters

What started out as a garage company with a grinding service later continued with an addition to the residential building for tool manufacturing, especially in the area of PCD tools. But with success, this work area was soon bursting at the seams as well. Actually, the Saxon entrepreneur could have made things easy for himself by erecting a modern company building on a greenfield site. But far from it. Just a few steps to the rear is a stately manor house dating back to 1443 and listed as a historic monument. Lehmann didn't take long to renovate the monumental building with great attention to detail. While precision tools for various industries are now manufactured in one wing, another part is made available for apartments. This is probably the only tool manufacturing facility in Germany in a historic setting. "And," he adds, "all debt-free. Many companies have had to close, especially in recent years, because they couldn't hold out financially. They went bankrupt or were sold. We are fortunately debt-free, which takes the pressure off us and provides free thinking."

How to plan when nothing can be planned

Shortages of raw materials, supply shortages, pandemics, war in Ukraine, energy crisis... The list could go on and on, says the 56-year-old entrepreneur. Times have never been more uncertain than they are these days. He would like to invest in a new machine, but he doesn't know whether there will be enough gas left for his company at the end of the year to be able to manufacture at all. Roland Lehmann is at a loss for words. He is also very critical of the dependencies on other countries. In the meantime, the whole of Europe has become dependent on China and Russia, for example. These are capital political mistakes made by governments, which unfortunately cannot be corrected with a small stroke of the pen. All raw materials are rising enormously in price, everything requires energy for the various manufacturing processes. Secretly, he says, it would take a momentary energy shutdown for people to realize how everything is intertwined. Unfortunately, many people are not aware of the threatening extent of an energy crisis.

Work-life balance crucial for success

If you don't find Roland Lehmann optimizing and designing his tools or talking to employees or customers, he prefers to pursue his hobby, hunting. At least twice a week, he goes out into his hunting grounds, takes care of the preservation of a species-rich animal population and enjoys the peace and quiet in the forest and in the meadows. As a hunter, too, similar attributes comparable to those of an entrepreneur are required, such as independent work, skill, a sense of responsibility, commitment and organizational talent. Good powers of observation and focused attention are also required. And if one wants to remain in the hunter language: Neither hunters nor entrepreneurs want to let game or orders "slip through their fingers," and only the game and not the business should "fall by the wayside." He can also switch off well in the evening with a glass of wine, with a view of his small animal enclosure including pond area next to the former manor. He has just ordered two partridges, he says with a wink. Here, too, there might be parallels to draw: The partridge is considered a so-called character bird of the open field.

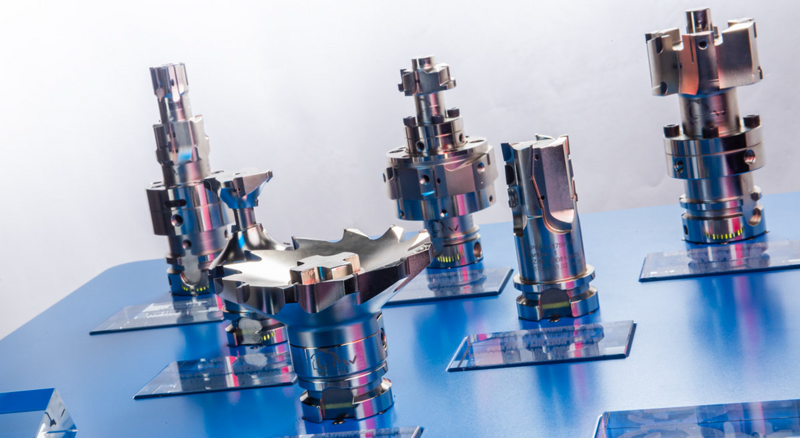

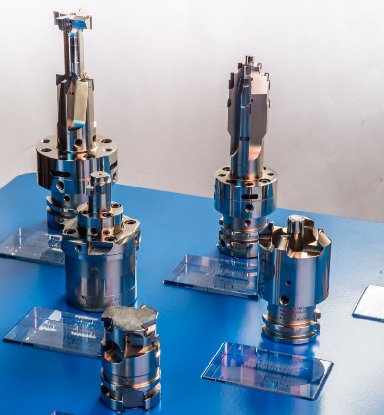

AMB as a growth spurt

Roland Lehmann is pleased that AMB can take place under "normal conditions" again. A trade fair lives from customer contacts and personal discussions. Entrance fees below 2G and the obligation to wear a mask, as at the GrindTec, keep visitors away and ensure little efficiency. That is why he is happy to present his special tools made of carbide and solid carbide, diamond and PCD tipped "face to face" again in September. He is looking forward to the challenges, about the customer requests that would come to him on the days of the fair. "Because," he emphasizes, "we don't sell the tool, we sell the solution. For this, we do our own engineering and design tools for the respective application area. In doing so, we cover a wide variety of industries. It is always a question of asking what the customer wants to achieve. After 30 years of presence on the market, the grown know-how and due to the extremely agile and flexible operational structure, we have positioned ourselves excellently on the market, are and remain a valued partner of our customers, respectively our new customers."

![[Translate to English:] InDiamond.world](/fileadmin/_processed_/a/1/csm_InDiamond_Logo_2021_1fb017de30.png)