On the road to success with vision and willpower

Ceratonia as a supplier of raw materials and quality since 1996

It is fair to say that the introduction of the now common CVD thick-film diamond in everyday production is definitely a merit of Reiner Dümpert. 25 years ago, he founded the company Ceratonia with the conviction that he would market this superior, but at that time absolutely unknown cutting material worldwide or customize it according to customer wishes. In the meantime, the one-man-show has become a representative internationally operating company with almost 15 employees.

Anyone who knows Reiner Dümpert knows that patience is not his greatest strength. Visions in his head, always driven by new ideas and definitely an above-average risk taker - that's how you could describe him in a few words. "When I saw the first free-standing CVD blanks from the US company Norton in 1997, I immediately recognized the potential of this cutting material. At the beginning of my self-employment, I helped Norton to market these products as an official distributor for Europe," says Dümpert. He even created the name Polydress (now Ceradress) for CVD dressing rods, which Norton then marketed worldwide. Finally, due to the successful marketing in March 1998 during a product presentation for about 20 tool manufacturers he received Norton Pioneers Award.

"When, after the turn of the millennium, the abrasives manufacturer Norton - for reasons that are still unknown reasons unknown to this day - ceased production of CVD diamond and was no longer able to deliver even existing orders, we were faced with a major challenge, challenge of continuing to supply our customers," Dümpert explains. But giving up was not an option for him. "I was faced with a major task: We were able to find a new supplier (SP3, USA) after some time, but for a rapid delivery of blanks to our customers we had to independently increase our capacities, especially for cutting the dressing rods," says the 62-year-old.

„We have always thought our way about the needs structure at our customers and have used this to bring forward relevant innovations into superhard cutting materials and the processes required for this tool market. As early as 1997, new diamond materials such as Ceraton CVD or Ceradress CVD, the machining by laser beam and finally also the vacuum brazing technology were initiated in the "creative workshop" Ceratonia and implemented with partners.“

Reiner Dümpert

The following situation slowed down the acceptance of the new Ceraton CVD cutting material: On the one hand, there was a lack of vacuum brazing and laser technology for subsequent machining of the non-erosive 100% diamond layer. In Germany, only a few tool manufacturers of cutting tools were initially able to vacuum braze cutting materials without carbide carriers. Others resorted to external service providers such as the Brütsch and Wabawaska companies. Until then, the cutting edges of Ceraton CVD were only machined with natural and monocrystalline diamonds by a complex grinding process with diamond wheels.

"The so-called global players in the cutting tool industry probably have been in a position to make the necessary investments, but they treated this market, which was new to all of them, stepmotherly from the very beginning. Until then, this was the domain of the classic diamond tool manufacturers. The use of diamond cutting materials was obviously more of a reduction in their sales of carbide tools for the "big players" - so even more than 20 years ago, the new Ceraton CVD was not all that interesting, just as the classic PCD had been years before. However, the manufacturers of tools tipped exclusively with diamond recognized "in the better the enemy of the good" and were ready for this innovation in polycrystalline cutting materials" is how Reiner Dümpert sums it up.

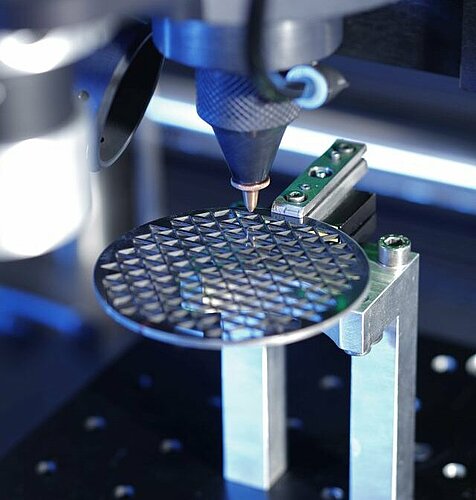

Another of Ceratonia's pioneering efforts has been to promote the possibilities for processing its CVD cutting material to potential customers: "The linchpin was, and still is, suitable laser processing. Laser technology was still in its infancy at the time. In the fall of 1998, Ceratonia presented the first laser suitable for this purpose - at that time from Laserpluss - to invited tool manufacturers in Würzburg. Although this could only cut blanks from the 26.2 x 26.2mm CVD blanks, it was the birth of the years that followed in the development of suitable systems," explains the mechanical engineer. Ceratonia got the ball rolling and, as a result, several manufacturers of tooling machines have further developed their laser systems. (e.g. Agathon, DMG, Ewag, Laserpluss Services, Rollomatic).

In the industry working group (participating companies: Riemke, Kieninger Technologie, Mössner, Laserpluss, Ceratonia) the topic of laser processing of CVD thick-film diamond was worked on and accompanied from the beginning together with the IWF of the TU Berlin. Laserpluss supplied a system for this purpose to the TU, Ceratonia the CVD cutting material. This enabled the institute's specialists to optimize the machining processes and soon produced fantastic results. Above all, Dümpert developed strategies at Ceratonia and the industry working group to first produce precise blanks from the base plates. In a second step, the tool manufacturers then began to machine not only the cutting edges by lasers but also chip breakers. The achievable edge sharpness eventually exceeded that of a ground cutting edge. Then the process repeatability had to be developed.

Tool manufacturers tended to borrow the "brazing technology" for CVD from the brazing process for the niche products natural diamond and MKD. Few companies had experience with the vacuum brazing required for this 20 years ago. At that time, however, the entire process was still not very well understood. Dümpert served with Dr. Flécher as a consultant to Messrs. Wigtec and financed the production of the first two prototypes of the newly developed vacuum brazing systems. The native of Lower Franconia was also resourceful when it came to launching the industry magazine Diamond Business. This was accessible to all suppliers and authors.

In 2002, for example, the trade magazine Diamond Business reported for the first time on the new CVD cutting material for the industry. It also supported its acceptance in the market and aroused interest among users who wanted even better tool lives than those achieved with PCD.

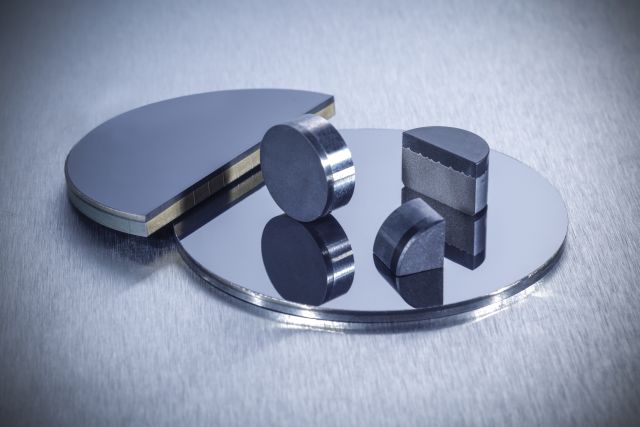

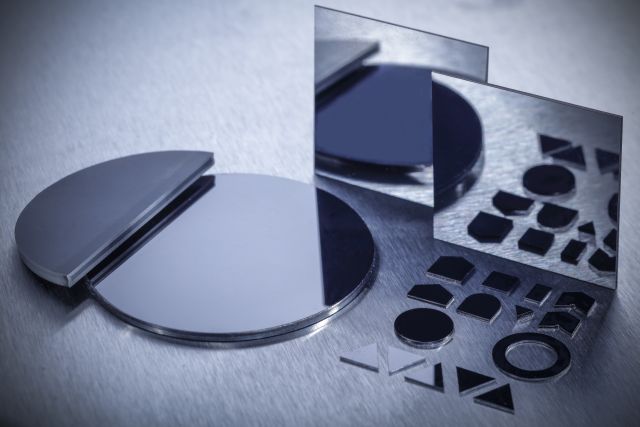

Stoney way

After 25 years, it can now be said that the cutting material Ceraton CVD and the dressing rods as well as the Ceradress CVD forming plates have become indispensable in many areas of production, thanks to Dümpert's pioneering work, among other things. An important milestone in the company's history was the focus and expansion of laser technology "in-house" as well. Like no other supplier, Ceratonia is able to offer the tightest tolerances (+/-20μ) and the smallest blanks for special applications in dimensions of, for example, 0.2 x 0.2 x 0.7mm. This also requires digital microscopy (up to 2,000x) to measure and optically control production and even the finest grit sizes and to control them optically. Thus, over the years, in addition to a wide range of PCD and CVD products, a comprehensive product portfolio has developed in parallel with quality assurance: screening of diamond, CBN, and natural grits to shape sorting according to customer requirements.

Dümpert's independence came about more as a consequence. The wave of redundancies at General Electric in 1995 also affected him. He had been working there since 1989 as a key account manager for northern and later central Germany. Thus, he began his "career" in the diamond and CBN raw material industry as a supplier for the tool manufacturers of the defined cutting edge as well as the sawing, drilling and grinding tool industry.

Reiner Dümpert remembers well: "Very quickly I developed a passion for industrial diamonds and superabrasives. Even before the birth of Ceratonia in June 1996, I pondered in my parents' attic studio at my father Lorenz's desk, how I could use the experience and knowledge I had gained in the industry in a targeted and meaningful way". In the end, he often researched the Internet into the night hours for companies known personally or by name. During the day, he contacted the companies and in the late afternoon, he says, he often used his bicycle to transport the once few packages to the post office.

Member of Supply Chain

„In our work, we must always keep in mind that as a raw material and tool supplier, we are integrated into the customer's workflow and our team must therefore act with absolute reliability. This means meeting deadlines, manufacturing or stocking the goods in the required constant quality and quantity and always deliver reproducibly. Our customers' tools must always perform on the machine what was specified and qualified. Thus, in addition to quality assurance (ISO certified), it is part of our principle that at least two employees are always familiar with each process. This means that the workflow is always maintained, even in times of illness or vacation."

Next generation at the start

Ceratonia has always grown with the increase in business. By 2000, Dümpert already had four employees, and others were steadily added. He converted the basement apartment of his parents' house into an open-plan office and the basement into technical rooms, while the executive office remained under the roof. His parents' apartment was the middle layer of the company sandwich. The everyday life was a stair up, stair down - entrepreneurially it went despite disloyalty of the suppliers and losses of employees (also twice to market companions), steeply upward! We were able to "reactivate" our diamond industry expert Bernd Hackel - formerly employed at Element Six - from retirement and win him as a top supporter for our team. He was looking for, as he put it: "a supplier as a new employer who has good product knowledge, has these products in his portfolio and with whom he can work at eye level". He found this in Ceratonia.

In addition to the support of his family, Dümpert receives the best possible support by junior staff in international sales. For example, he happily names "foster son" Christopher Löhner in advising international customers and Lisa Schnös, who actively supports him in this. Representing the rest of the team, he names his "pillars" - the left and right hands: four times Lisa and Sophia. One of them started as an apprentice at Ceratonia and is now one of his "top girls," he says proudly. "I can rely on our team. As of 2012, there was no alternative in terms of space for further expansion. We were bursting at the seams and needed a company building that was also representative for international customers," Dümpert recalls. At the beginning of 2014, Ceratonia moved to Ebelsbach - about two kilometres as the crow flies - into over 500sqm of office space.

Also privately on „expansion course“

His three grown-up children have now found their place in the company, Reiner Dümpert is pleased to report. It also seems to be true for Adrian (22), Gianna-Maria (21) and Laurence (18): Once you have worked in the diamond business, it is hard to get away from it. Each of them has his or her own area of responsibility and is involved in the main decisions, just as the employees are. "For example, Adrian has already been able to take on essential tasks in the market launch of the Ceradite PCD rounds in 62mm diameter, where his colleague Sabine Zenglein does not miss a beat in the internal sales department. Gianna-Maria is now learning the products from scratch in the Quality Assurance department. And Laurence, together with Patrick and Christoph, optimizes and programs the laser systems and supports product qualification projects. and supports product qualification projects," explains the medium-sized managing director and father.

Reiner Dümpert has always had the vision to be in the first place with his products when it comes to tool production or the industrial use of diamond and CBN: "Fortunately, we are not forced to offer only what a production of grit from diamond produces, but we work together with various manufacturers - the market leaders of the respective product types - as a free independent distributor. This is true not least because over 10 years ago we did not have the best experience with the loyalty of some raw material manufacturers. Therefore, in the now 25 years of experience, we have qualified the best products from the respective productions (also for natural diamond) and market them as hardly any other supplier to this extent under our own product names. With an open ear to the market, exclusively for diamond and CBN, we probe, categorize and test the quality of existing products and new manufacturers in the interest of our customers. Starting with micron powders across all grain sizes, up to polycrystalline cutting materials CVD/PKD. As well as in the preparation of natural diamond, we see our function as a reliable partner in Europe on the spot. A partner who guarantees the quality of the cutting materials and also the supply chain, especially in this uncertain time of the global pandemic as a raw material supplier."

Reiner Dümpert believes that his employees are also clearly responsible for Ceratonia's success and continuous. "It is only thanks to my employees, their identification, motivation and team spirit that all this has and is all this possible. In myself I see the burning fire that the others must have to ignite. I am also thinking of all those who have since gone on to pursue their goals elsewhere. Especially today in these unpredictable and difficult times, it is wonderful to know a strong team in the background. How we always work with each other instead of against each other in the team and with customers and suppliers: that has to be right for everyone today and tomorrow. Decisions have short distances but are well considered. For strategic or technical mistakes, I and now the young people in the owner-managed company always have to take personal and financial responsibilities for strategic or technical mistakes. I pass on my know-how about the market and products to my children and employees every day so that the "Ceratonia trees" can continue to take root and bear fruit.

A word in conclusion

"For many years, by the way, all the well-known manufacturers have been manufacturing with syntheses mainly in Asia. We partly cooperate with products from the same productions as the former three global players of the "good old days". We have our products manufactured according to our own specifications. Contrary to the suppliers from the "Far East", as the Chinese suppliers are often disguisedly called, we see ourselves "on top" again and again as engineering partners and suppliers of tailored solutions instead of merely acting as traders, as some market companions do," concludes Dümpert.

VITA

Engineer Dümpert was born in '59 and graduated from the Schweinfurt University of Applied Sciences with a degree in mechanical engineering, specializing in design and development. He found his first job in the export department of the rolling bearing giant FAG Kugelfischer (now Schäffler) in Erlangen. From 1986 to 1988, he set up a subsidiary in the state of Connecticut, USA, to sell and service hydraulic rescue cutters to fire departments. "That was already the first step into self-employment, because my part at that time was already a start as a one-man show. I found an empty warehouse, three offices, a company car and a storage hall there. Four employees were quickly added. This was then repeated, so to speak, because the compulsory expansion of all rooms down to the basement in my parents' house accompanied the steady growth in sales as well as in personnel," he describes with a smile. Influenced by his stay in the USA, he calls his employees all by their first names and mentions that this also contributes to a very good cooperation and a personal and binding "corporate behavior" and real team building. When he started in 1996, he was completely "self-employed" and responsible for all operational matters: From visiting customers, packing packages, quality inspection, purchasing, accounting to EDP. Today, he has become a sought-after medium-sized businessman and maintains numerous business relationships all over the world.

![[Translate to English:] InDiamond.world](/fileadmin/_processed_/a/1/csm_InDiamond_Logo_2021_1fb017de30.png)