Rethinking grinding - Könnemann goes to next generation

Ronny Könnemann had just become self-employed with his new company KW-Technology, had said goodbye to his father's company for personal reasons, both mentally and spatially, when his father Gerhard Könnemann died at the age of 82 after almost five decades of entrepreneurial activity and he was appointed sole heir to the three companies.

Besides all the emotional ups and downs after the death of his father, the first thing to do was to take a sounding. Three companies, KW Abrichttec, G&N and Logomatic wanted to be managed and successfully led into the future. And there was still the own, fourth freshly established company in the bunch. In an interview, Ronny Könnemann talks about the burdens, but also the opportunities that now present themselves with the company succession, where he sees the market and how he faces the challenges of the future.

Mr. Könnemann, the company succession could actually have been arranged in a simpler and more structured way. You knew KW Abrichtec, G&N and also Logomatic from the bottom up. Even as a schoolboy, you were familiar with repairing spindles and you also completed your extra-occupational studies in your father's company here in Mainaschaff. You worked with your father for more than 20 years. Nevertheless, the succession to the company did not go according to the textbook. What were the reasons?

My father was a visionary, always had a lot of ideas and saw opportunities in different products and companies. He started in 1964 with KW-Antriebstechnik, now KW Abrichttec. As a studied mechanical engineer, he founded the company Logomatic a few years later in 1972 and developed grinding machines there. In 1994 he invested in a third company, G&N in Erlangen. Still other companies were acquired in German-speaking countries, but he subsequently liquidated them. In my opinion, he "got bogged down" in many areas and lost the overview of his "ventures". He no longer had a fixed focus, but got lost in many individual tasks. In addition, he could not part with many useless things and so, over time, more and more garbage accumulated in the workshops. In short, my father "danced at many weddings," didn't want any more changes, and he had a hard time handing over responsibility. For a long time, I tried to find my role in my parents' business, and in the end it seemed easier for me to seek my own path to independence. I promised all employees that in a worst-case scenario I would be there the next day. Then, a few months later, my father passed away and I was faced with big decisions to ensure the future viability of the companies. So I came back as promised.

My focus is on significantly strengthening the core competencies of KW Abrichttec and Logomatic. My family and I live close to Mainaschaff, and because of the proximity alone, I wanted to use the opportunity there to set up and manage these two companies for the future. In the meantime, almost a completely new team is working here in Mainaschaff. Not that I was dissatisfied with the previous employees, but most of them were about to retire. So it was necessary to find and train new employees, so that I had to bear "double wage costs" for a certain time. However, what is the most difficult thing in such a situation is to break the baked-in culture in the heads - that was not so easy. Today, I now have a very good young and committed team, professionals with a good know-how, who are happy to take on complex tasks and face up to the reorientation of the company. Furthermore, it was necessary to appoint a managing director for G&N Genauigkeitsmaschinenbau Nuremberg. Hermann Moos seemed to be very suitable for this and he also had the confidence to take over the business activities. Fortunately, he fills his role excellently, so that I hardly have to be involved in the organizational processes there. We are working hand in hand in our current project for the semiconductor industry, and very successfully. This allows me to concentrate 100% on the two companies here in Mainaschaff without losing sight of G&N completely. First of all, I had to clean up the workshop and dispose of the waste. I removed several tons of material, respectively scrap, here in Mainaschaff, including a lot of older machines, its hodgepodge. In the first step, this gave us the opportunity to set up new and efficient structures. In the meantime, we are working with an ERP system, which helps the work processes and transparency immensely. Originally, I wanted to modernize everything from the ground up. The administrative rooms have a nostalgic feel. I always jokingly greet my visitors with the words, "Welcome to Honecker's pants." Admittedly, brown fabric wallpaper, hunter green conference chairs, arranged with brown shellac tables do seem a bit historic. Nevertheless, I had to take care of the important business first. Everything else was put on the back burner for the time being. There is indeed a preliminary construction plan with investments, estimated today at about 2.5 million - but everything in its own time.

Ronny Könnemann

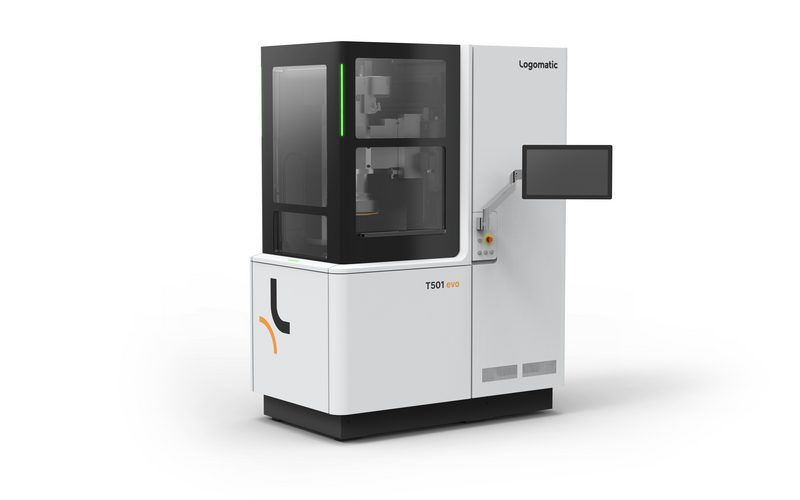

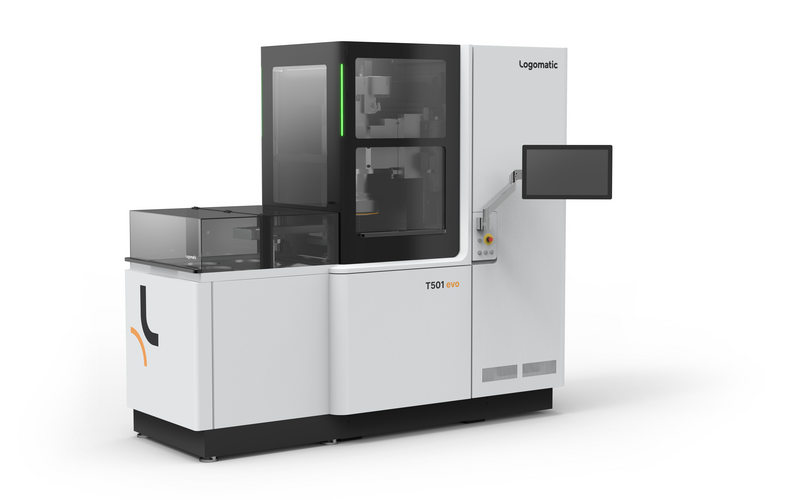

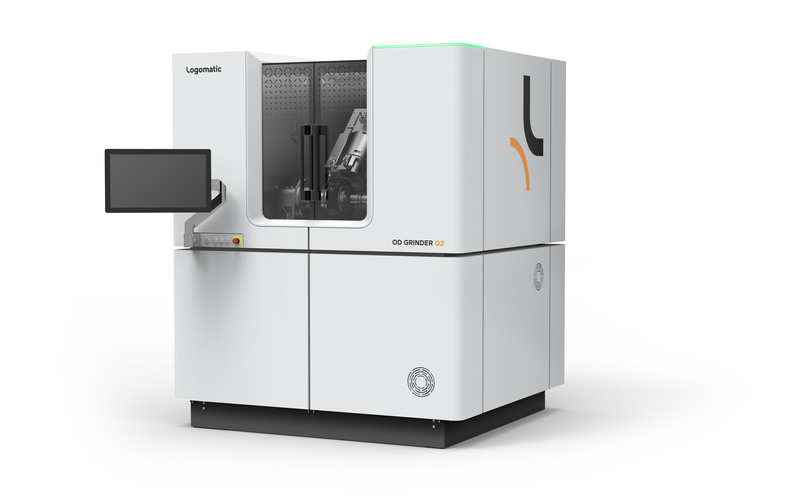

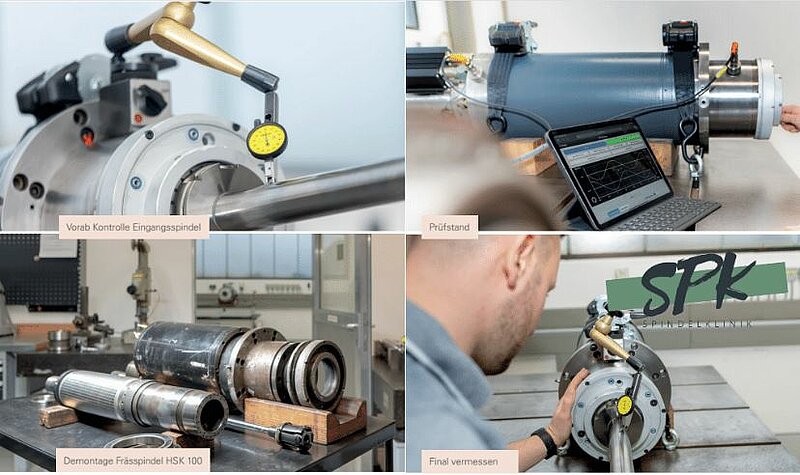

G&N in Erlangen produces different products but serves the same markets. G&N develops and produces high-precision surface grinding machines for metal and semiconductors. Incidentally, the first silicon wafer was ground at GMN back in 1964. It is a product range from smaller manual to larger machines with a focus on automation. KW Abrichttec, on the other hand, here in Mainaschaff, in addition to spindle and dresser manufacturing, also has a service the Spindle Clinic, a manufacturer-independent repair of spindles. The third company, Logomatic, concentrates all its efforts on the construction of external cylindrical grinding machines for the semiconductor industry. An absolute project for the future, in my opinion. In the last 18 months, we have pushed ahead with the development of two different grinding machines. One machine for external cylindrical grinding and the other for surface grinding. This is our strongest current focus right now, a product development that excites and inspires us all.

Ronny Könnemann

You had also mentioned your own company, KW Technology. What role does it still play today in the ranking of the "Könnemann Group of Companies"?

In fact, today it only plays a role on paper. I had set up my own factory building in Aschaffenburg with KW Technology and a complete production line. In the meantime, everything has been moved here to Mainaschaff and integrated. Nevertheless, for a variety of reasons, I have not yet deregistered the company. There were still too many question marks, especially with regard to the estate.

I see very good prospects and high growth years for the global semiconductor market. Therefore, I am also very focused on the external cylindrical grinding machine and on the surface grinding machine for processing silicon carbide blanks, so called boules. We started with the prototypes and are constantly working on improvements. For example, for the prototype we first started with a cast welded frame, added additional components such as granite plate and console, all components which today have long delivery times and cost a lot. In the meantime, we use cast mineral concrete with integrated media connections, which simplifies and shortens assembly times, good for the overall project to serve the customer faster. It is important to me, especially in this area, to take advantage of the opportunities that arise, and I therefore also invest very purposefully in competent skilled workers, or rather I am always on the lookout, applications are welcome. Together with my team, I would like to be perceived as a stable and solid partner in the future. And of course we do not want to lose sight of our spindle clinic either. Traditionally, we have a wealth of experience in spindle construction, both in milling spindles and grinding spindles. And we can score with a high level of consulting competence. The fact that both G&N and Logomatic also serve the mechanical engineering sector means that we can offer a convincing service package.

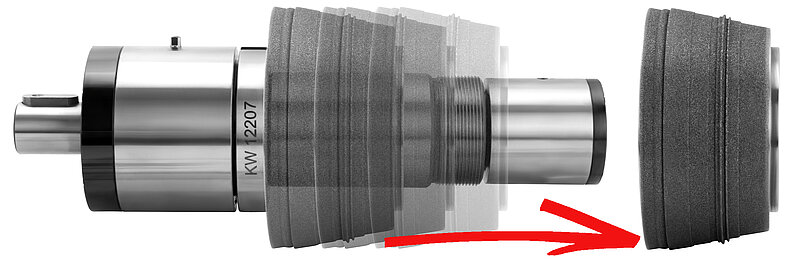

As already mentioned, I had worked with my father for 20 years. But even at an advanced age, he could not and would not relinquish responsibility. At some point, a colleague and I had the idea of modifying a conventional KW product. We had developed a simple and common expansion solution for a dressing mandrel. I immediately did business with a renowned turbine manufacturer in England and had this idea patented. And this innovation also gave me the leap into self-employment in 2019. But just a few months later, as already mentioned, my father passed away, so I wanted to bundle the competencies around spindle technology in one place again.

What were the stages in your life? Do you have or did you have an affinity for mechanical engineering?

No, I taught myself most of it. My original training was as an industrial mechanic. In my opinion, training as a craftsman is a very good basis in any case. After another year as a journeyman, I was then employed by my father. For 20 years I saw nothing else, but I developed my own ideas and conceptions and also questioned procedures and processes in the company again and again. I can't create CAD drawings myself, but I understand them blindly and when talking to the design department, I pass on my ideas for product development and emphasize what I value. This creative development pleases me the most. I enjoy working with our designer in a goal-oriented way, we have known each other for 15 years and it goes hand in hand with him.

To be honest, I admit that I used to have everything else on my mind than following in my father's footsteps. My father was a typical workaholic and until I was twenty years old, we hardly had anything to do with each other, he was hardly ever at home. I had led a crazy life until I became a father young. So to speak, a small turning point in my life. Everything was put to the test and I turned around 180 degrees. In 2011, I then completed a dual degree program at the University for Executives in St. Gallen (HSG). On the one hand, this brought me forward in terms of my personality, and on the other, it greatly enriched and expanded my knowledge. I wanted to implement and apply a lot of things right after graduation, but unfortunately my hands were tied by my father.

Despite all the difficulties that arose in working with your father, what positive things were you able to take away from that time?

In fact, an indescribable amount. My father's legacy has led me to where I am today. I liked his innovation the most, but the implementation was not good, which was always regrettable. I saw a lot of things with him and often disagreed with them. You could say I did a "contrarian study" with him, but with the same goal. There were some principles that he gave me on the way, which I like to adhere to very much and that is the responsibility towards the employees. Come what may, the employee is entitled to his wages, and on time. But of course I have also learned to be strong and to grow a thick "skin". I no longer let many things get so close to me.

Fortunately, I was able to bring many of the "construction sites" I tackled to a positive conclusion. All three companies were brought forward. For KW Abrichttec, for example, I brought the test bench technology of the spindle clinic up to date for a high investment. We are able to thoroughly test motor spindles up to 50kW drive power, which shows the customer our professionalism. Nevertheless, the last three years have been very nerve-racking, especially the situation surrounding the vexed issue of Corona. As soon as I took over the company, Corona came around the corner. In my opinion, and now increasingly from other sources, it was a "planemie" with all the negative consequences for the companies and for the population, which can no longer be denied. Since then, we have all had to deal with massive supply problems and the energy crisis is now doing the rest, not to mention the current situation in Ukraine. The shortage of materials and the delay in deliveries are preventing me from moving forward with the growth of the companies in the desired way. My customer wants to become the largest silicon carbide producer and I would like to grow together with them. But since some parts cannot be delivered, and I in turn am constantly put off by my suppliers, my hands are then tied and I am unfortunately always thwarted in my actions. This is already a story that annoys me quite a bit. I am aware that it is the same for everyone, but it should not and must not become an excuse.

I am an optimist and I am not a fearful person and I do not let myself be driven into any fears. I inform myself in all directions and I am interested in the most different ways of thinking. Basically, I think it's important to question everything. That's the only reason we've been able to move a lot of things forward and be innovative. By definition of our government, I am a lateral thinker. A few years ago, this was someone whose method of thinking, within the framework of creativity techniques, was used to solve problems and find ideas. Suddenly, this term is "framed" and has been bad-mouthed. I stand by my opinion and will always have a backbone. I think it is important not to be discriminated against because of one's opinion. What I care about is actually the future of our children. If the plans from the World Economic Forum in Davos are actually implemented as they are already announcing today, I am horrified about it and I am at a loss for words. It is about transhumanism and absolute control of every human being and making people dependent. But of course everything is well packaged and also the media unfortunately do their part so that people do not feel alarmed.

To bring it to the point: What we are currently experiencing is the systematic destruction of the middle class by left-wing eco-socialist policies. Never since the end of World War II have Western countries had their backs against the wall as they do today. The list of wrong policies of the globalists who want to gain even more power over the peoples, even more control with fear of Corona, of the climate apocalypse or the self-instigated war in the East is long. Russian sanctions, self-inflicted inflation, new financial bubbles, wobbling Euro currencies, rising national debts, restrictions in agriculture especially in the EU countries, lack of natural gas for many products, lack of diesel fuel, disrupted production and supply chains, destabilization of the world economy, danger of mass unemployment and popular uprisings, recession, danger of war maybe even nuclear, controlled mass immigration and forced migration of industry. The mixture cannot be more explosive.

This is no longer a conspiracy theory, but a fact that anyone can research for themselves. The self-appointed federal government is a joke in my eyes and justice, as well as the truth always win in the end, they just unfortunately need longer than the spread of a lie.

I was only a visitor at the AMB in Stuttgart in September. I liked the fair very much and it felt like a time before Corona. It seemed very dynamic to me and the exhibition halls were very well attended. This year we have deliberately refrained from exhibiting yet, but I expect that in 1 ½ years we will present ourselves with the Könnemann Group at the Grinding Hub. This is because we are targeting our customer base more precisely with the grinding exhibitions. Grindtec could also be interesting together with Intec in Leipzig, but in my opinion it will never again reach the former importance. We can only hope together that in the future the course will be set in such a way that it will still be worthwhile to manufacture here in the German, respectively European economic area and that the concerns and needs of the entrepreneurs will be taken seriously. Otherwise, the trade fairs would also lose their raison d'être.

Personal vita of Ronny Könnemann

Ronny Könnemann was born in 1982 in St. Etienne, Loire France and grew up from the age of three in Mainaschaff near Aschaffenburg. Already at an early age he started to deal with spindle technology. Even as a schoolboy, he helped himself to pocket money by repairing spindles and always looked over the shoulders of his father, who had dedicated his life to mechanical engineering. Ronny Könnemann initially decided on an apprenticeship as an industrial mechanic with a large industrial group and he quickly realized that in such a large company he could only live out his creativity and his urge for self-realization to a limited extent. Therefore, after a year as a journeyman, he was drawn to his father's company. But it was to be another two decades before he was able to take over the management of the company.

In the past three years, he managed to reorganize the "Könnemann Group", to free himself from "old burdens" and now he would see himself in a position to lead the individual companies stably into the future, if it were not for the unspeakable decisions of German and also European politics. So he can only underline the statement of the German professor for economics, Christian Kreiß, who defined Baerbock and Habeck as order killers of the German economy. Supply bottlenecks and horrendous energy costs will ensure increasing deindustrialization and a blatant loss of prosperity, the entrepreneur is certain.

Ronny Könnemann, the son of a South American mother with Japanese roots, describes himself as an extremely spirited, empathetic, helpful and assertive person, some character traits that sometimes get in his way, but can also be beneficial, as he emphasizes. A major highlight in his life was the birth of his son Patrice, who 16 years ago put a stop to his crazy life as an "enfant terrible," as he calls it.

The man from Lower Franconia has now been happily married for five years to Natalie, who has become an elementary help in the company on the one hand and is always on hand to give advice on important decisions on the other. Together with two friends and his wife, Ronny Könnemann is also working on an app called "Huggster," a project that aims to bring closeness and love back to people worldwide by allowing real physical hugs to be sent around the world. It's a whole new approach, the likes of which have never been seen before. In this app development, too, passionate, enthusiastic work and the joy of doing things are always in the foreground, in true Könnemann fashion.

![[Translate to English:] InDiamond.world](/fileadmin/_processed_/a/1/csm_InDiamond_Logo_2021_1fb017de30.png)