Vollstädt Diamant - 30 years of the highest standards in quality assurance for industrial diamonds and CBN

About the 30th anniversary, the generation change, the latest measuring technology and the foundation of SPR Abrasives, the new supplier of superhard cutting and grinding materials

At tranquil Lake Seddin, just outside the capital Berlin and in the immediate vicinity of the famous asparagus region of Beelitz, Prof. Dr. Heiner Vollstädt founded Vollstädt Diamant 30 years ago. The former start-up has since become one of the world's most established companies in the field of quality inspection and sorting technology for industrial diamonds and CBN. At the beginning of 2020, Prof. Vollstädt took his well-deserved retirement and handed Vollstädt Diamant over to his daughter, Ute Härtig-Vollstädt, who has already been responsible for other companies in the family for 20 years.

In the interview with her and her husband, Daniel Härtig, who also works in the family business, we also talk about the many innovations they have worked on in the recent past. These include the successful launch of the new advanced instruments DiaInspect DLM and DiaSusz in 2022 as well as the current development project in the field of micron production. Furthermore, there are exciting details regarding the foundation of the joint venture SPR Abrasives, with which they will set new standards in the field of superhard cutting and grinding materials as early as fall 2023.

Ms. Härtig-Vollstädt, what was the idea behind Vollstädt Diamant 30 years ago?

30 years is a really long time and before I gladly answer your question, I would like to take our anniversary as an opportunity to sincerely thank our employees and customers for the trustful cooperation during these 30 years. We are very proud and happy to have employees and customers who have been with us since day one, and of course we are delighted with every employee and customer we have gained during this time. My father studied mineralogy at the Humboldt University in Berlin and subsequently devoted his entire professional life to diamonds and superhard materials. In 1993, he decided to become self-employed and founded Vollstädt Diamant. At an early stage, he concentrated there on quality testing and sorting technology for industrial diamonds and later also CBN. In addition, over the course of time, further ventures, projects and research work were added, all of which were dedicated to industrial diamonds and which have also been continuously developed and expanded to the present day. By handing Vollstädt Diamant over to me, we were able to ensure that all family-owned diamond companies could continue to exist under one roof and benefit from the associated synergies. We have successfully mastered the generational transition in an extremely difficult market environment and are very pleased that my father is still available to us today as a competent advisor.

Vollstädt Diamant has its roots at Seddiner See in the greater Berlin area. This is where you operate your only production facility. Nevertheless, you are internationally positioned...

We are an owner-managed family business and in fact operate only one production facility. This is the only way we can meet the high quality standards we set for ourselves in our development and production, and which our customers rightly expect. For our new subsidiary SPR Abrasives, we are in the process of setting up additional sales locations in Antwerp (Belgium), Sarasota (USA) and Shanghai (China), which will start operations shortly. In addition, we have sales partners in China, Hong Kong, Korea, Japan, Taiwan and the USA.

You are talking about the subsidiary "SPR Abrasives". What can the reader imagine by that?

With our new subsidiary SPR Abrasives, we see ourselves as a refiner or producer of cutting and abrasive materials, depending on the product category. It is founded together with two no less well-known players in the superhard cutting materials market: Gemmata from Belgium and American Superabrasives Corp. (ASC) from the USA. SPR aims to become one of the world's most reliable and renowned suppliers of superhard cutting and abrasive materials. SPR Abrasives' vision is to set new standards for superhard products and services in order to gain the trust and loyalty of its customers. This will be achieved by offering first-class in-house products, by having an outstanding quality control system, by investing in continuous product innovation and technological development, and by better understanding customers through close cooperation and continuous evaluation.

Customers can expect products of the highest quality, which are subjected to the strictest controls in our in-house laboratory facilities in the Berlin area. Naturally, we rely on our own Vollstädt diamond technology for this. The quality control results will also be available online for all products in order to gain the trust of our customers. The advantages for our customers are obvious: high vertical integration and direct access to the value chain, great product understanding, highest possible quality and reliability.

In our in-house production, the cutting and grinding materials can be coated as desired to meet individual customer requirements. Despite this additional qualitative refinement, the entire product range is offered at competitive prices. SPR intends to develop customized coatings in close cooperation with its customers and to keep setting new standards for innovation. SPR is always happy to work with customers to find the ideal solution. By integrating in and at our production site, we ultimately also make a contribution to the localization of supply chains desired by many market participants. Initial products include CBN powders, diamond powders for resin bonds and metal bonds, in both mesh and saw grain sizes. The required micron powders are also offered, besides SPR will also distribute natural diamond powders. In addition, with SPR, we also offer some exclusive services in Europe. Customers can have products they have purchased elsewhere, or old stock, cleaned or sifted and subjected to the same rigorous testing in SPR's laboratories. One important service is recovery, where it is possible to partially recover the powders used in electroplating. This makes it possible to reuse parts of these materials, which is much cheaper than buying new powders.

The newly founded company SPR Abrasives is certainly a milestone in Vollstädt Diamant's corporate history. What else is new to report?

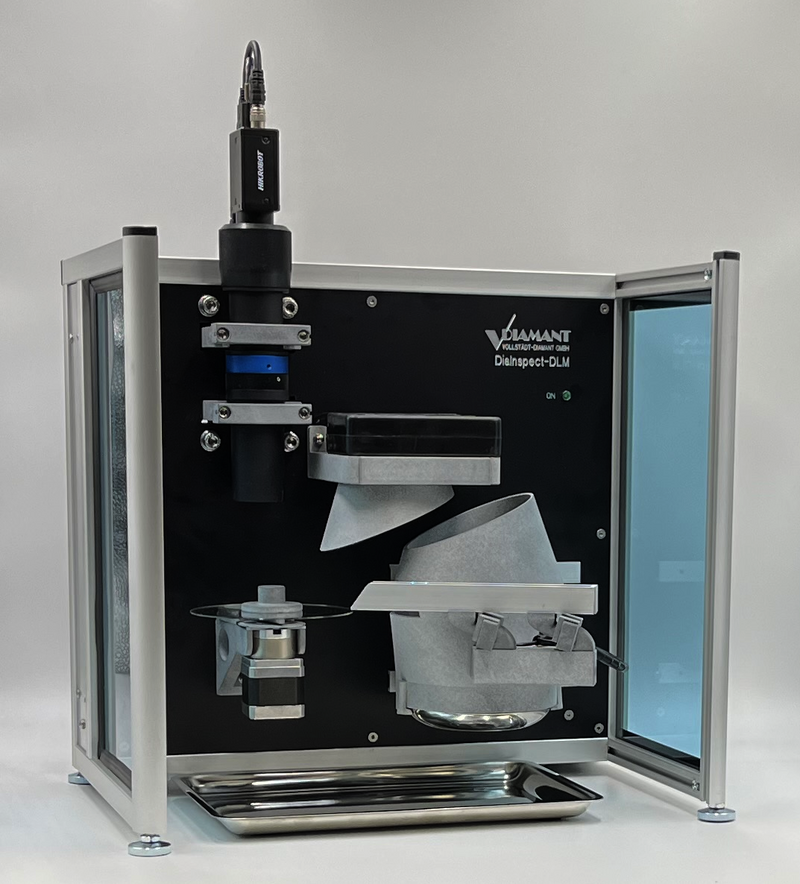

There are a number of innovations that I would like to mention. First, we have developed a highly specialized image analysis system. It is called the DiaInspect DLM. This is an optical particle analyzer optimized for analyzing a large number of particles in a short time. The advanced optics and illumination components adapted to the requirements as well as a completely revised concept for sample preparation now set new standards. Secondly, we have launched our DiaSusz, a new benchtop instrument for measuring magnetic inclusions. This makes it possible to better characterize the properties of industrial diamonds. In addition, we are currently working on an optimized measuring device for micron production, as we see an increasing demand for corresponding image analysis systems. We see high potential in this and hope for a successful market launch before the end of this year.

To put it in a nutshell, what is the core business of Vollstädt Diamant, a company with a long tradition?

Our core business includes the following areas:

- Development and manufacture of high quality testing and sorting technology for industrial diamonds and CBN.

- Laboratory service for classification, evaluation and quality testing of industrial diamonds and CBN in our own independent laboratory according to European FEPA standard

- Development of devices, coatings and surface treatments according to special customer specifications

- Refining and distribution of diamond and CBN cutting materials, including saw and abrasive grains, micron powders, always prepared and quality-assured

- Production and sale of diamond and CBN tools for machining metal, ceramics and glass.

In the field of quality and sorting technology, Vollstädt Diamant has distinguished itself in a very innovative and also high-performance way and has thus become known beyond all borders. Can you agree with me?

Absolutely. We have always been particularly innovative and technically leading in this area - and of course still are today. Just think of our well-known single-grain strength testers DiaTest S, DiaTest SI and DiaTest ASM or our special image processing systems with which we have set new standards. These are used, for example, by manufacturers of diamond and CBN cutting materials worldwide in their quality assurance departments every day with great success.

What are the benefits for the customer when he uses your products?

Our customers fundamentally benefit from the exceptional quality and reliability of our products. They can rely on us to always set and continuously maintain the highest standards. Of course, this also applies to our services - whether in the laboratory area or in individual consulting. It is always our goal to offer products and solutions that meet our customers' requirements. This results in a multitude of advantages for our customers. In the area of quality assurance, for example, customers can use our measuring instruments, such as the DiaInspect P, directly in their production. It delivers both reliable and highly precise measurement results, which are essential for efficient quality assurance and thus stable production. The cost-effectiveness of using our equipment is therefore practically self-evident. The longevity of our products also contributes to this. Many of our instruments have been in daily, productive use for well over ten years. We carry out regular services for the replacement of wear parts as well as repairs even over a very long period after commissioning. In addition, we have also been offering factory upgrades of existing equipment for some time. After all, even the most advanced technology is subject to constant improvement. In this way, we enable our customers to participate in technological progress without having to make a complete new investment. This makes economic and ecological sense. In the field of cutting and grinding materials, we clearly distinguish ourselves from our competitors, who often serve this market only as dealers. We are much more than that. Anyone who buys cutting and abrasive materials from us also receives what we consider to be obligatory quality assurance. No cutting or grinding material leaves our premises without quality assurance. It goes without saying that we rely on our own technology.

To what extent do customer wishes flow into your work?

We maintain very close contact with our customers and are therefore in constant dialogue. Therefore, it is obvious that time and again, especially long-standing customers, inform us about new needs or requirements. We always see these as food for thought, to which we are only too happy to devote our time. The agile orientation and working methods of our development team enable us to react to them flexibly and, above all, promptly. For example, it is thanks to such a request that we have completely redeveloped our aforementioned DiaInspect DLM. The reactions have shown us that this product is a valuable addition to our portfolio.

![[Translate to English:] InDiamond.world](/fileadmin/_processed_/a/1/csm_InDiamond_Logo_2021_1fb017de30.png)