Lehmann-UMT GmbH

Hide categoriesShow categories

Our range of products and services that we offer within the sectors:

Custom-fit solutions for oil, water and emulsion

Lehmann-UMT is a globally active filter manufacturer, as well as a specialist in the filtration of liquids. The company stands for sustainable innovation in the field of filter and conveying technology "Made in Germany". With a high vertical range of manufacture, from the recording of your requirements, through development and production, to worldwide service, we are your strategic partner. Benefit from custom-fit solutions for your application to realise optimisation processes, efficiency increase and cost savings.

The medium-sized family business located in Pöhl in Vogtland was founded in 1945 as a repair and craft business. Today, approximately 110 employees ensure the highest quality and functionality of the systems.

Filter technology

With many years of experience and competence in filter construction, we contribute to the development of rationalisation processes. Our strength is the large selection of highly modern filter systems, which makes it possible to always find the filter system that is exactly optimised for your application. The technology of Lehmann-UMT sustainably supports all processes from grinding, turning, drilling, milling to lapping.

Conveyor technology

As a developer and manufacturer of individual conveyor technology, we also offer customised consulting, development and production as well as service and maintenance of the systems in this area. Take advantage of our experience and expertise to manufacture the conveyor system that meets your requirements and high demands. The conveyor systems can be used for short and broken metal, needle and cast iron chips, as well as for steel and wool chips in dry and wet processing.

Product information

StingR® ultra-fine filtration

A special highlight is the newly developed StingR® ultra-fine filter system. Widely applicable for the machining of HSS, hard metals, ceramics or mixed machining, cooling lubricants, emulsions, oils as well as process water can be sustainably treated. In combination with our systems, or integrated into your existing structures, up to 30% of the energy costs can be saved and the service life tripled. The modular design and intelligent sensor technology, in combination with the use of different filter elements, enable a precisely fitting process-related filtration and lead to an enormous reduction of the disposal volume. The pneumatic automatic backwash ensures low maintenance. The StingR® ensures stable production processes, reduces wear on the machines and offers the highest quality in production.

Visit our second website

StingR | Ultrafine Filtration for HSS, Carbide & Mixed Machining

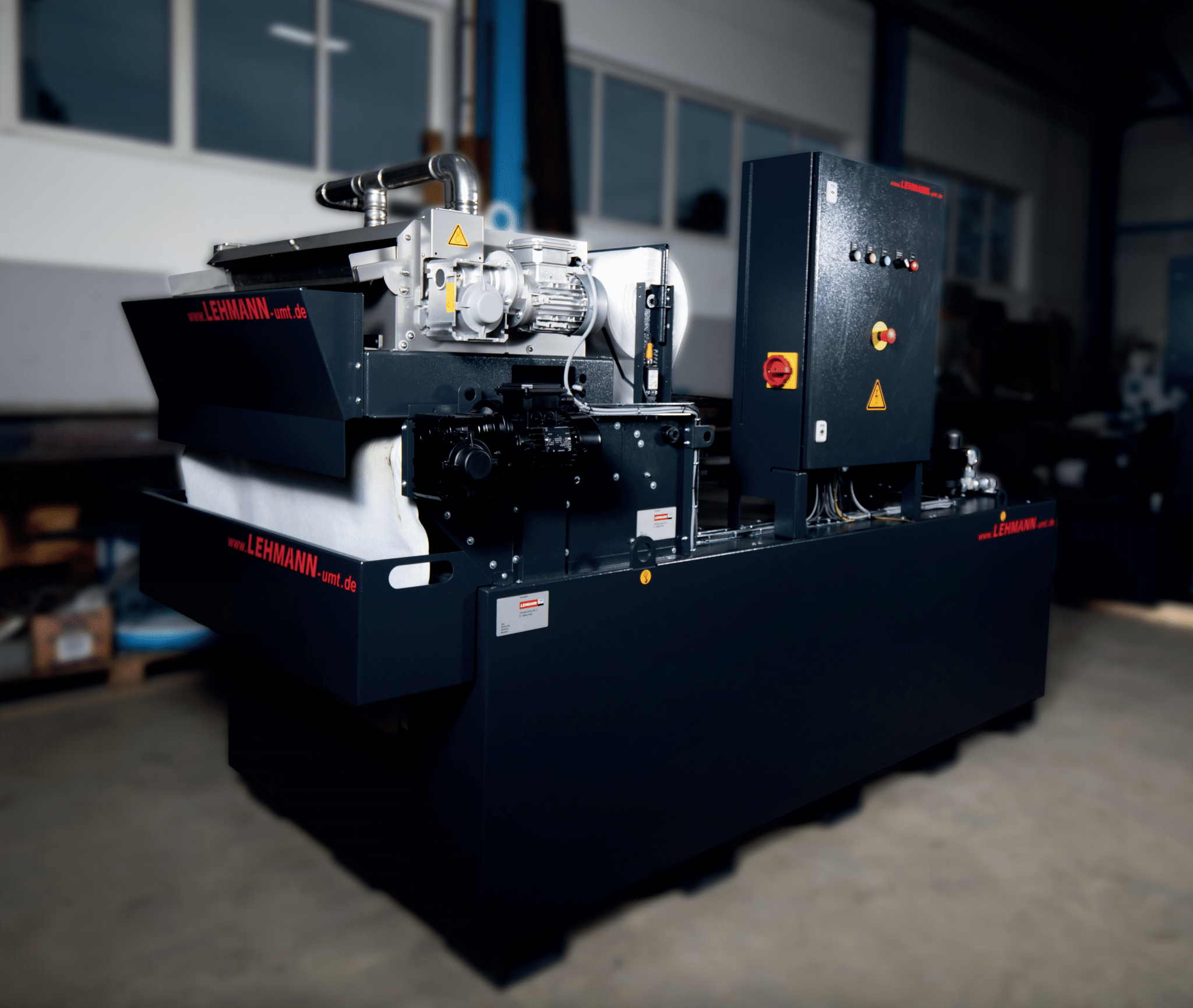

Suction belt filter:

Lehmann-UMT has developed a new generation suction filter from the compact filters that have been successfully placed for decades. The continuous filter system is not only suitable for a high volume of dirt, but also meets the highest demands on filtration quality. In a continuous filtration process, high litre capacities are achieved in the smallest installation space. The self-cleaning suction system makes filter aids redundant and ensures minimum maintenance. The suction filter impresses with its low energy consumption, cost efficiency and high cost-effectiveness.

![[Translate to English:] InDiamond.world](/fileadmin/_processed_/a/1/csm_InDiamond_Logo_2021_1fb017de30.png)