Change and Growth

Walter strengthens its market position with new leadership and strategic acquisitions.

Nothing is as constant as change – a guiding principle that aptly describes the current developments at Walter. Two years ago, Mr. Christoph Geigges (President and CEO of Walter AG) was appointed as the new managing director, marking the beginning of a new era for the company. The recent acquisition of Frezite in Portugal, which brought 450 new employees into the "Walter family," underscores the company's ambitious goals. These strategic decisions are part of a well-defined course for further development in the dynamic tool industry.

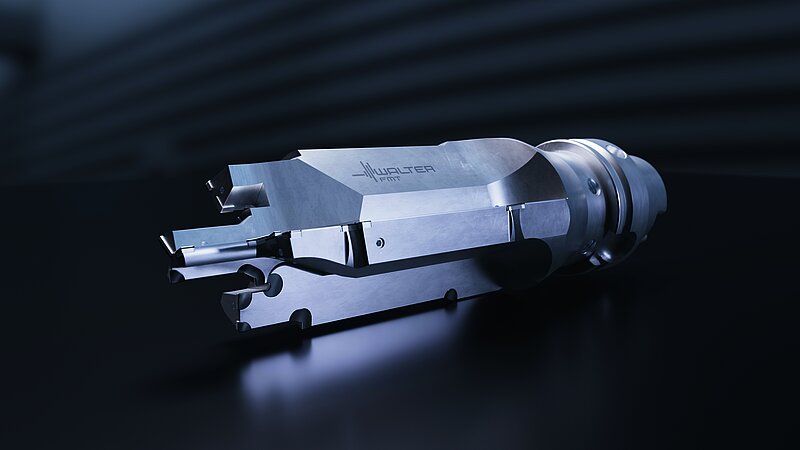

The transformation is particularly evident in the context of the electrification of the automotive industry. While Walter already holds a strong position in many materials, there was still room for improvement in lightweight material machining. To strengthen its presence in this area, Walter sought a reliable partner – and found a promising one in Frezite. Frezite not only provides critical expertise in PCD tools but also offers innovative solutions in workpiece clamping, a new and exciting field for Walter as it aims to position itself as a comprehensive provider.

Since the acquisition nearly two years ago, Walter FMT has been successfully established in the market. With a clear focus on the future, the company is poised to solidify its position in the industry and continue to expand its capacity for innovation. Christoph Geigges, who previously served as CFO at Walter, brings fresh energy and new perspectives to this exciting phase of the company's development and addresses key questions in an interview.

DIAMOND BUSINESS: Does the FMT location in Balingen still exist, or was it closed as part of the acquisition?

Christoph Geigges: The Balingen location no longer exists. We already had a PKD tool location in Niefern, which is also not far away. We decided to consolidate both locations, as the existing Walter location is larger and offers a broader portfolio and more extensive services. This decision allows us to work more efficiently and provide our customers with optimal custom tool solutions. Almost all employees have transferred to the other location, which has allowed us to retain valuable expertise. Although the commute may be longer, we are pleased that we were able to retain many experienced and talented employees.

How has the integration of FMT expanded or changed the PKD tool portfolio, and what new opportunities does this create for Walter?

Through the integration of FMT, our volume has more than doubled, and in the PKD tool sector, it has nearly tripled. At the same time, we have significantly expanded our expertise and fostered greater collaboration within the team. This has led to new ideas and more complex tools, reinforcing our focus on customer needs. In the past, the focus on PKD tools, which are 99% custom-made, was not always a top priority. However, we’ve made significant progress: Our clear customer focus, enhanced expertise, and new, more complex tools have greatly improved our PKD portfolio.

Where do you see the unique strengths and approaches of Walter FMT in the PKD tool sector? How do you differentiate yourselves from other manufacturers?

For us, it’s important to emphasize that we’ve significantly advanced in terms of expertise and volume. While we are not yet one of the largest players in the PKD sector, we are now far more interesting and renowned than before. Walter was not primarily known for PKD tools, but with Walter FMT, we are taking a new approach. The benefit for our customers lies in our comprehensive offerings: In aluminum machining, we not only offer PKD tools but also carbide solutions. Walter stands for engineering competence – we work closely with our customers to develop tailor-made solutions. From the design phase through tool production to service, we apply our engineering capabilities to achieve continuous improvements. We are not just focused on simple PKD tools but on engineering solutions that provide real value for our customers. This concept is the core of our market differentiation.

Moreover, the Frezite acquisition also included workpiece clamping devices. This complements our offering with key elements on the platform of a full-service provider. Additionally, we’ve added measurement systems for post-processing. We can now offer comprehensive solutions that reflect the engineering expertise that Walter represents.

What is your long-term vision for Walter FMT, and what goals do you aim to achieve?

We aim to be recognized as an established name in the PKD and lightweight machining sectors. Our goal is to continue growing, gain market share, and eventually be among the key players in the industry. To achieve this, we have several important milestones ahead. There are numerous markets we can still tap into, in which Walter is already present. Particularly in the field of fine machining of holes in steel and cast materials, we have customers, but Walter FMT is not yet strongly represented. Our goal is to become an agile and innovative partner for various business sectors and strengthen our local presence.

What role does the technology center in Tübingen play for your customers, and how important is it for Walter's continued development?

The Technology Center in Tübingen is of great importance to us. Here, we focus on developing detailed solutions together with our customers. In a way, it also partially replaces traditional trade fairs, as we can work directly on customer solutions on-site. Additionally, we have opened a similar technology center in the USA, which also plays a crucial role in our continued development. Both centers contribute significantly to Walter's success.

How important is the focus on international markets for Walter’s future development, especially with the newly opened technology center in the USA?

Since mid-2019, we’ve had a challenging market situation here in Germany, especially in the automotive sector. The COVID-19 pandemic and the subsequent recovery have made things even more difficult. The market is stagnating, and it’s tough to gain volume, as many providers, particularly from Asia, are flooding the market with price competition. However, I’m optimistic that Germany, with its innovation power and strong industry, has the potential to initiate a growth cycle. Automation and other developments could play a key role here. Therefore, I am confident we can regain momentum. Nevertheless, Walter is currently pursuing the “Go Global” strategy. In this context, we are exploring new markets and do not want to rely too heavily on the domestic market.

What markets are currently the most important for Walter?

The largest and most important market remains Germany. The USA and China are in second and third place, both playing a decisive role in our business development.

What considerations were behind the decision not to participate in AMB in Stuttgart this year, and do you plan to be present there in the future?

My predecessor believed that trade fairs were not necessarily the optimal marketing tool for Walter, and due to COVID-19, trade fairs have had difficult years recently. As CEO, I visited EMO in Hannover last year and was also at AMB this year. My impression and opinion have changed. I believe we should carefully evaluate trade fair participation and consider which ones make sense for us. I can easily imagine that Walter will be present at AMB again in the future. The technology centers will also play a crucial role. There, we can implement customer-specific solutions and presentations excellently. We have the opportunity to speak very specifically about ourselves and our full offering and collaborate closely with our customers.

What changes have occurred in the field sales department since the integration of the competency brand Walter FMT?

I am convinced that we need to be closer to the customer and should specialize more in customers who use PKD tools. In Germany, we have therefore built teams that are focused on PKD tools and the needs of our customers. This is a new development that is increasingly being driven forward, and it is already clear that it is moving in a positive direction.

Mr. Geigges, how do you manage to meet the high expectations and pressure as a relatively young CEO?

The pressure in a corporation can indeed be of a different dimension compared to, for example, a family business. It is important to keep the strategic developments in clear focus while also considering the financial reality. Balancing these aspects requires careful prioritization and communication within the team. It is wise not to transfer all the burdens to the employees, but to involve them according to their roles and responsibilities. With my two young boys and through sports, I find a good way to relax and clear my head. Taking breaks is crucial to staying productive and focused in the long term. This way, I can be a stable and reliable support for both the company and my team.

Who is a good advisor for you?

An important advisor is the Walter management team, consisting of my closest colleagues. We regularly align and openly discuss various topics; openness and transparency are key. In addition, I have a small, strong network of mentors and experienced colleagues who provide me with valuable perspectives. For example, a retired Walter employee supports me as a technical trainer to better understand our products. The exchange with our customers is also very important to me. I strive to create a broad base of information and support to make well-informed decisions in the best interest of Walter.

VITA CHRISTOPH GEIGGES

Christoph Geigges was born and raised by Lake Constance in the district of Konstanz. After completing a dual degree in business administration, he initially moved to Switzerland, where he began his career in the finance department of a company in the aluminum processing industry. He then transitioned to the pharmaceutical industry, where he pursued an international finance career for about ten years. During this time, he gained his first leadership experiences, followed by a stay in Dubai, and later became Co-Managing Director in Saudi Arabia. Due to his family situation, he desired to return to Germany. In search of an international company, Christoph Geigges came across Walter, which opened up new perspectives for him. He has been with Walter for four years, initially as CFO and, for the past two years, as CEO. He looks back on a successful career and is proud of his role as CEO. At Walter, he sees himself as a learner, and his daily work is characterized by numerous conversations and exchanges with many people. Mr. Geigges is appreciated for his friendly nature and openness, which make him very popular within the company. Christoph Geigges is always approachable, listens well, and enjoys considering various perspectives. Together with his team, he is now working to elevate Walter to a new level of success and set the course for a successful future.

What will future products look like?

This is indeed a complex question! Future products will need to be strongly aligned with the future needs of customers, particularly in the PKD sector. In Germany, the focus will be heavily on efficiency and productivity. Innovative solutions will be crucial in achieving these goals. We cannot compete with wages from countries like Eastern Europe or Asia, but we must focus on our innovation, efficiency, and automation. Close collaboration with machine manufacturers and the integration of tools with sensors will also be important, for example, to determine the optimal time to replace inserts or tools. Sustainability will also play a key role, especially regarding the reprocessing of PKD tools. This requires a holistic approach and innovative strategies to meet the challenges of the future.

Source | DIAMOND BUSINESS

![[Translate to English:] InDiamond.world](/fileadmin/_processed_/a/1/csm_InDiamond_Logo_2021_1fb017de30.png)