DEMANT Der Schweizer Spezialist für MKD-Werkzeuge

For over seven decades, the name Demant has stood for precision, quality, and innovation in the manufacturing of diamond tools. Founded in 1952, this family-owned company, based in the picturesque Düdingen (CH), has become an indispensable partner in the tool industry. Under the dynamic leadership of Yves Grandjean, who has been guiding the company's fortunes in the third generation since 2019, the Düdingen-based company has not only maintained its position as one of the industry leaders but has continuously expanded it. A look into the past reveals the deeply rooted traditions and the immeasurable expertise that has been built up over generations. From the outset, Demant focused on the production of diamond tools for processing non-ferrous metals and plastics, primarily for the booming watch industry – a sector where precision and reliability are of invaluable importance. Yves Grandjean's grandfather, a true pioneer of his time, laid the foundation for the company in an era when there was only one other manufacturer of diamond tools in Switzerland.

Monocrystalline diamond tools, renowned for their extraordinary hardness and wear resistance, continually open up new dimensions in precision machining and expand possibilities in various application areas. Yves Grandjean and his team at Demant prove that tradition and innovation don't have to be opposites but can complement each other and strengthen the company. The combination of decades of experience and the constant pursuit of improvement and perfection makes the Düdingen-based company an outstanding example of Swiss corporate culture and technological excellence.

DIAMOND BUSINESS: Mr. Grandjean, has it always been your desire to follow in the footsteps of your father, or grandfather, respectively?

Yves Grandjean: Of course, the work of my grandparents and parents, all of whom were involved in the same company, has always fascinated me. As a child, it was exciting for me to be a part of it. I fondly remember my early days here at the company. I still keep my first official paycheck from 1993 to this day. Originally, I started my apprenticeship as a polymechanic in machine maintenance at a different company. My focus at that time was on different aspects of technology and production. However, about 17 years ago, there was a turning point in my career. At that time, my father's company faced a bottleneck in grinding wheel production. It was a challenge outside my previous area of expertise, but that's exactly what intrigued me. And what can I say? That experience fascinated me. I quickly realized that this was where my passion lay, and I wanted to learn more and delve deeper into it. Since then, I haven't been able to let go of the industry. After 14 years of working in the company, it was clear to me that I wanted to continue the family business. However, my small family and my wife also played a crucial role. Together with my wife, I carefully considered all aspects and scenarios to ensure that we as a family could take this step together; Full steam ahead!

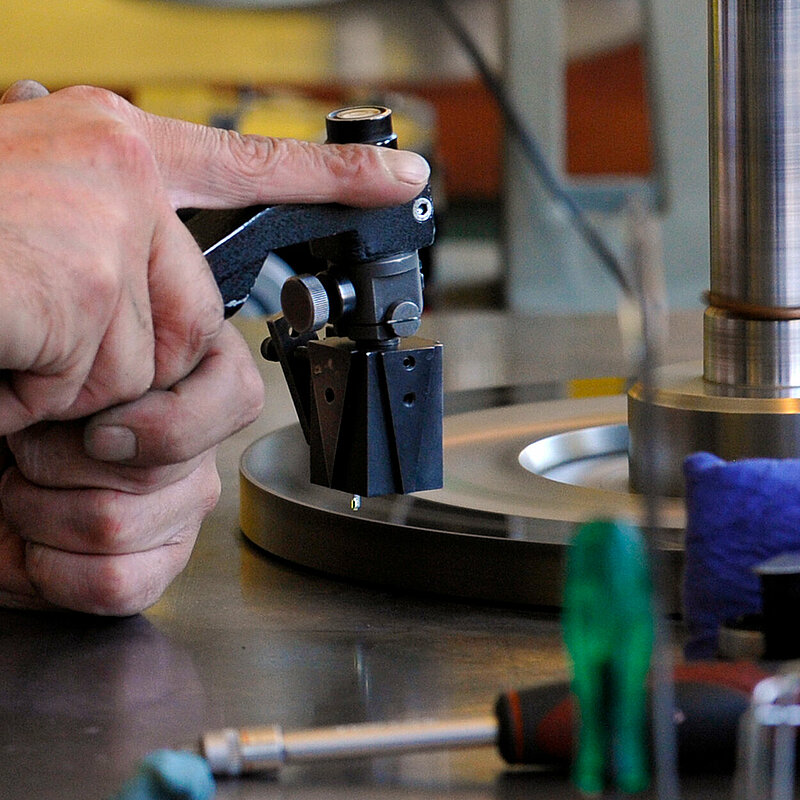

The world of diamond tool manufacturing is indeed a very special one, almost one could say, a small world of its own. Everyone involved in this field is, in their own way, a specialist. The production of diamond tools, especially working with monocrystalline cutters, is even more special than the already highly complex production of polycrystalline diamond tools. What personally fascinates me about this specific niche is the fact that despite all the advanced technology we use today, a large part of the work still involves "manual labor." There is a lot of "human touch" in each tool we manufacture. Processing monocrystalline cutters requires not only a deep technical understanding and precision but also a high level of patience and dedication. Each tool is a small work of art in itself, bearing the signature of its maker. There are not many manufacturers worldwide that specialize in this type of production, which makes this area even more exclusive. And in this niche, I have found my professional home. It's a world that is constantly evolving, and I couldn't imagine a better place to be.

How does Demant successfully differentiate itself from its competitors in an industry that is relatively small but still highly competitive?

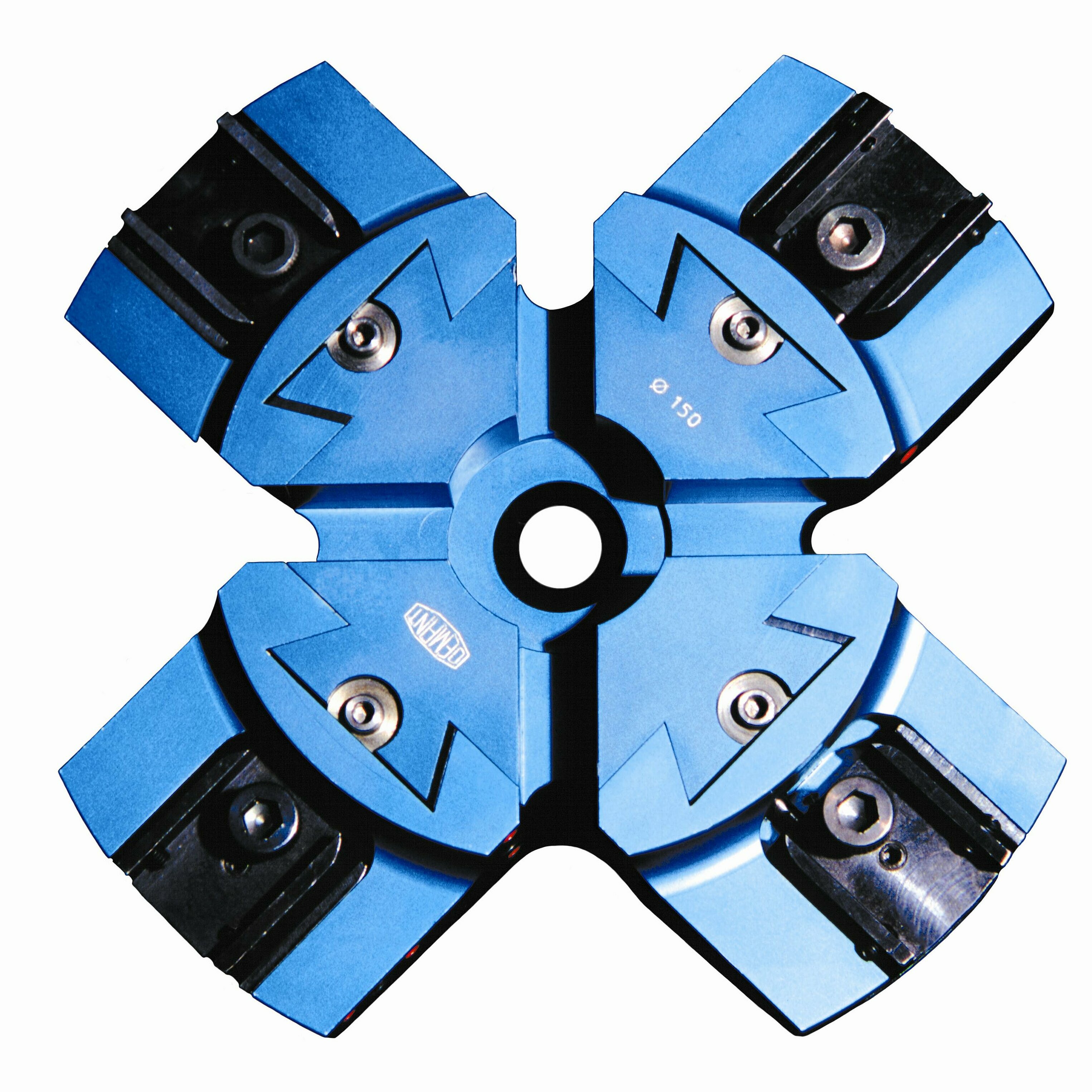

Our key advantage over competitors lies in our ability to react quickly and flexibly to customer needs. As a small company with 15 dedicated employees, we benefit from a very flat organizational structure. As a technician at the helm of the company, I always think solution-oriented and deeply engage with the challenges our customers face. This approach enables me and my team not only to identify problems but also to develop effective solutions to overcome these challenges. My team supports me 100 percent, allowing us to respond within 24 to 48 hours. Another difference from many of our competitors is our approach to production concepts. While 90 percent of our products are based on modern carrier materials, we only use the traditional steel-clamped method in exceptional cases, which was previously common. Instead, we prefer, for example, carbide as a carrier material and increasingly use inserts in turning. Our goal is to simplify and standardize processes not only for ourselves but also for our customers' setup personnel. We also take new approaches when selecting diamonds. We quickly decided to use lab-grown diamonds, placing great emphasis on quality, often to the dismay of our diamond suppliers. My personal experience in grinding has taught me how important the precise selection of diamond quality and its various orientations is, and I have transferred this high standard of accuracy to our entire product portfolio. The combination of fast responsiveness, innovative manufacturing concepts, and an uncompromising commitment to quality makes us a competent and reliable partner in the diamond tool industry.

Given the strong price pressure in the European market, how does Demant, as a Swiss manufacturer, manage to assert itself successfully?

It's true, thriving in an environment characterized by intense price pressure presents a significant challenge. However, it is precisely in this demanding situation that we find our strength. Our focus is on customizations and challenging projects that require exceptional standards of quality, precision, and tool performance. In areas where other manufacturers may hesitate or cannot or will not meet the specific needs of customers, we find our niche. That's when it becomes particularly exciting for us. Our willingness to step in where specific expertise and a flexible approach are needed makes the difference and brings us joy in our work.

For 18 years, you've been involved in your father's business. What changes have occurred in your company and in the industry as a whole during that time?

In recent years, we have navigated through a remarkable period marked by both economic prosperity and political and social crises. At Demant, despite these challenges, we have made significant progress and experienced clear development. We are particularly proud that we have been able to almost double our workforce. This step was crucial to expanding our capacities and optimizing our production processes. Additionally, we have made considerable investments in new production machinery, especially in the areas of laser processing and high-vacuum soldering. Through these modern technologies, we can not only increase our manufacturing efficiency but also elevate the quality of our products to a new level. Furthermore, we have invested in additional measuring instruments to further improve our quality assurance processes and ensure that our products meet the highest standards.

At the end of 2022, there was a change in tenants in the building, and there was an opportunity to utilize an additional 600 square meters. However, at that time, there were significant uncertainties due to the war in Ukraine, and we were concerned that potential markets could collapse. For this reason, we decided at that time to continue renting out the space rather than using it ourselves. In hindsight, the decision to continue renting may not have been the wisest choice from today's perspective. Growth continued relentlessly, despite global crises occurring. For example, we did not anticipate an increase in the luxury segment of the watch industry. Although we renovated an adjacent garage to expand our capacity, we must honestly say that we are slowly reaching our limits again.

When I took over full management five years ago, he was still present every day, supporting me with his wealth of experience. Then came the Covid pandemic, forcing us all to make changes. My father transitioned to remote work and began to gradually step back from the day-to-day operations. However, he still serves as a backup in accounts payable and accounting. My mother also still handles some administrative tasks, albeit to a lesser extent. It reassures me to know that both are still present in the background, especially if things get tight. Occasionally, I still seek advice from my father, particularly regarding financial matters. His decades of experience and support continue to be invaluable to our company.

Our products are used in a variety of industries, primarily in the watchmaking industry, but also in areas such as medical technology, plastics industry, precision mechanics, turning, and optical industry. We anticipate significant growth, especially in the optical industry sector.

Our goal is to continually advance the development of technology and traditional craftsmanship. With a focused eye on the future, we strive not only to meet current market standards but to actively shape them, setting new benchmarks to be a pioneering company. Our ambition is to be recognized as a globally renowned brand for innovative solutions in our specialized field.

The requirements for the materials to be processed are becoming increasingly demanding, especially in the field of non-ferrous metals. Diamond tools offer an ideal solution here with their unparalleled lifespan and surface quality. We almost exclusively use monocrystalline diamonds manufactured in the laboratory. This not only makes procurement much easier but also ensures consistently high quality. We are well equipped to meet future requirements.

As a Swiss company, we face particular cost pressures. Additionally, we find it increasingly difficult to find qualified employees, especially since a lot of manual work is still required in our operations. Nonetheless, we remain committed and determined to share and pass on our enthusiasm and passion.

The products of the future will become increasingly complex, as evidenced by current trends in design. Due to advancing digitization, the market demands simpler communication channels, faster delivery times, continuous quality assurance, traceability, planning security, and all-in-one solutions.

VITA YVES GRANDJEAN

Yves Grandjean grew up in the picturesque canton of Fribourg, where he developed an early affinity for technology and mechanics. This passion led him to pursue training as a polymechanic, a profession that demands precision and meticulousness. At 37 years old, he specialized in the challenging task of revising large milling and turning machines, where he could fully showcase his talent for precision engineering and technical understanding.

His thirst for knowledge and the desire to expand his skills led him to delve into the field of diamond grinding, where he underwent additional training. This specialized skill enabled him to work in a niche area of precision machining. To combine his technical skills with business acumen, Yves also invested in technical-commercial training. This combination of skills has allowed him to work more effectively at the intersection of technology and business, particularly as he works on digitizing production in his company.

Yves Grandjean's day begins early, every workday at 4:30 a.m. As one of the first in the company, he enjoys the morning quiet, allowing him to focus entirely on starting up or converting machines and getting an overview of the production process. Then, the first sip of coffee tastes even better, a small ritual that gives him strength for the day. What particularly appeals to the young father of two about his work is the opportunity to be creative. He finds solving complex problems and tinkering with technical challenges together with his team to be particularly enriching. Yves Grandjean's life motto can be aptly summarized by the Swiss-German saying "Z'läbe fägt," which means "Life is beautiful, life is joyful." This expression reflects his optimistic outlook on life, a deep joy in existence, and an appreciation for all the possibilities that life offers.

Source: Demant and Diamond Business

![[Translate to English:] InDiamond.world](/fileadmin/_processed_/a/1/csm_InDiamond_Logo_2021_1fb017de30.png)