Diamond Meets Precision

How the VVBM Series Redefines Vacuum Brazing. IEW GmbH from Austria Sets New Standards in the Production of High-Performance Diamond Tools.

A COMPANY THAT UNDERSTANDS HOW PRECISION IS CREATED

“We wanted to make vacuum brazing more transparent, efficient, and controllable,” says Martin Schweikhart, founder and managing director of IEW Inductive Heating Systems GmbH. More than 25 years ago, it all began with a thesis on induction heating at TU Vienna – today, IEW is a specialist in induction and vacuum brazing systems and a reliable partner for customers who demand the highest quality and process reliability. With the development of the VVBM Series (Vertical Vacuum Brazing Machine), the company has engineered a brazing system specifically designed to meet the requirements of modern high-performance manufacturing – particularly in the field of polycrystalline diamond (PCD) tools, CBN, CVD, and other advanced materials.

THE TECHNOLOGY: PROGRESS AT EVERY LEVEL

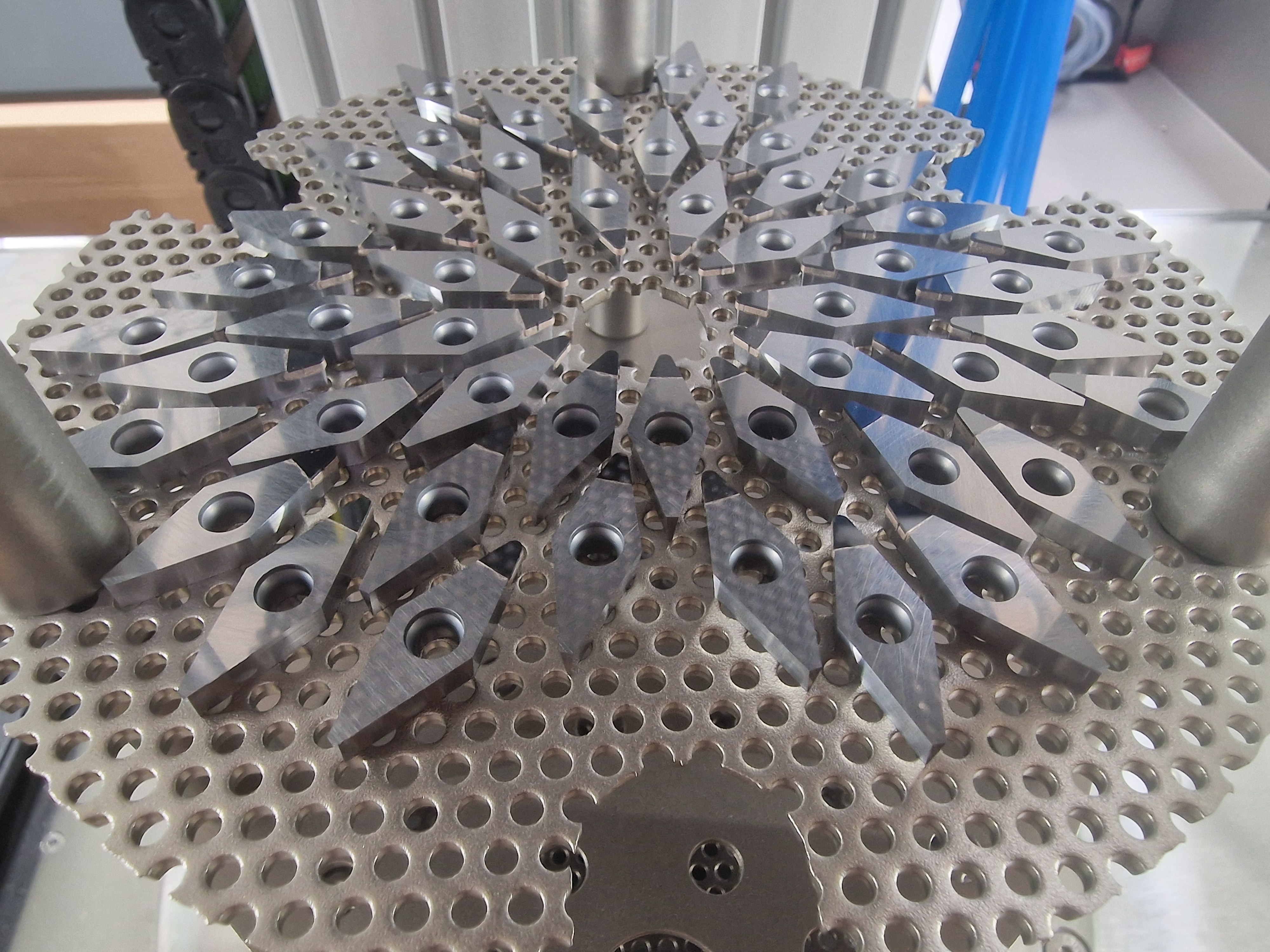

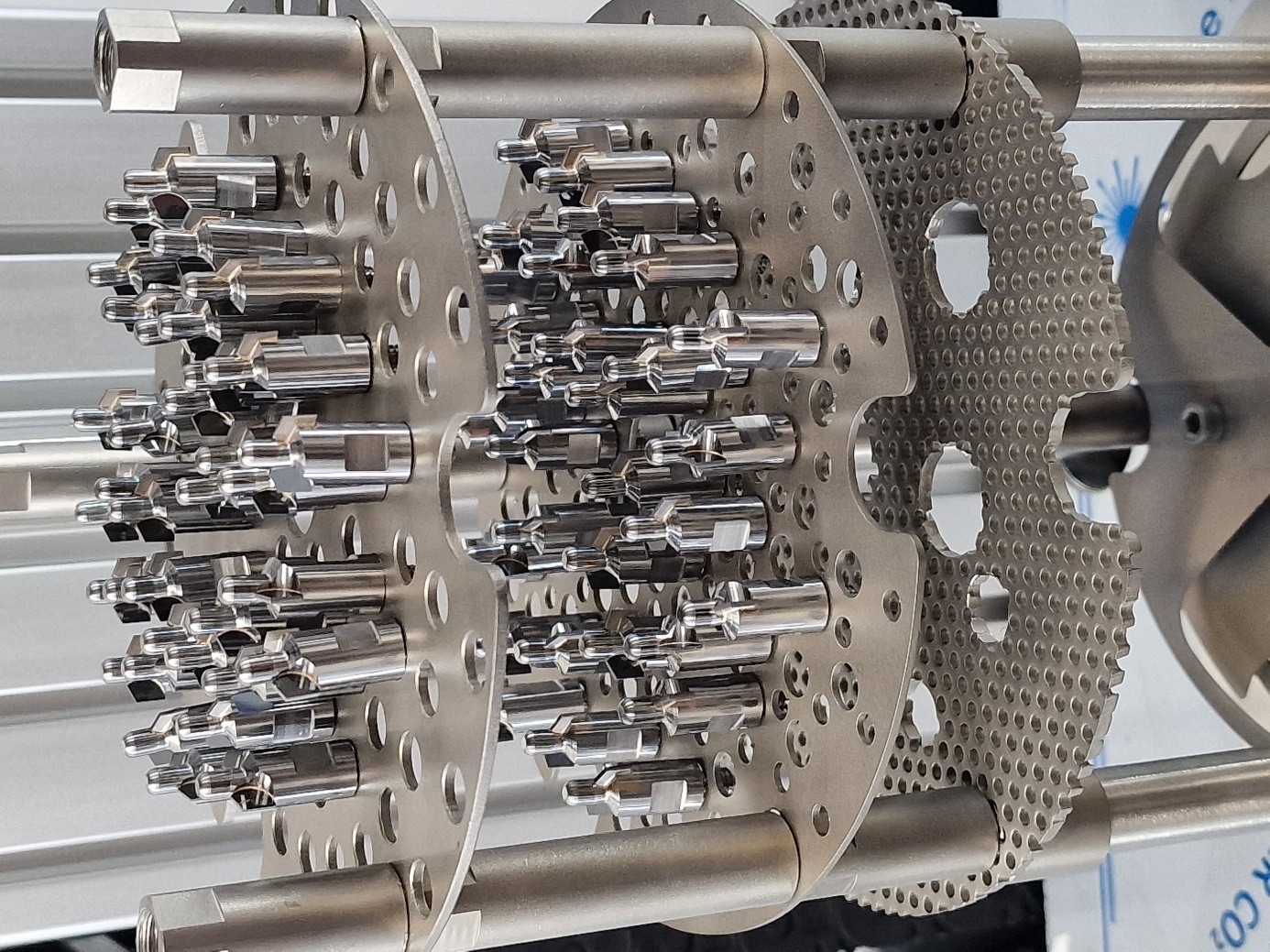

At the core is the vertical design of the vacuum chamber. While conventional horizontal systems quickly reach their limits, IEW creates more space and structure through vertical arrangement:

• Up to 800 PCD inserts per batch

• Up to 14 levels with 25 mm spacing

• VVBM150: 240 mm / VVBM200: 360 mm heating zone

The result: maximum utilization per cycle, improved cost efficiency – and sufficient capacity for complex diamond tools, which is a decisive advantage, especially for series production.

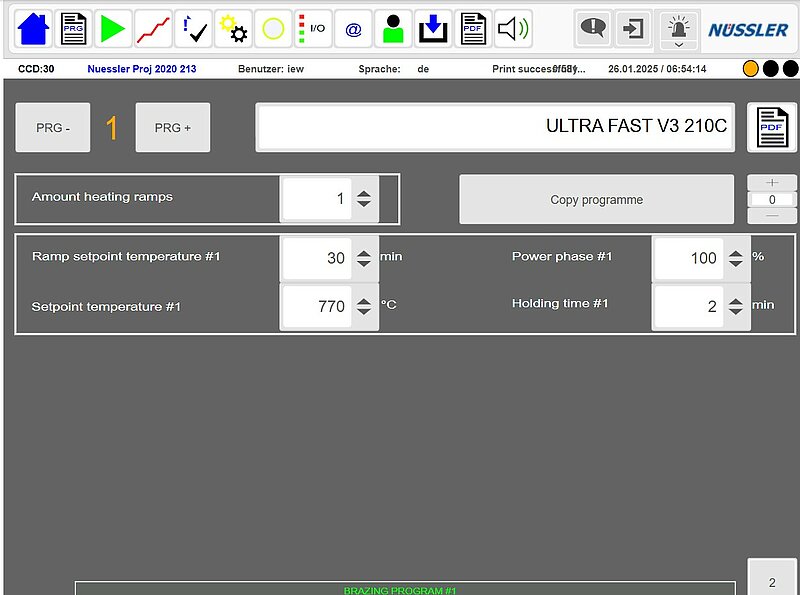

PATENTED TEMPERATURE MANAGEMENT: THREE ZONES, ONE GOAL

The centerpiece of the system is the patented 3-zone temperature control. Each zone can be regulated independently – in the VVBM200, for example, with 120 mm per zone (80 mm in the VVBM150). This enables the simultaneous brazing of different materials in a single process run:

• PCD at <700 °C

• CBN or CVD at >800 °C

Thanks to this separation, users save process time and energy while maximizing output.

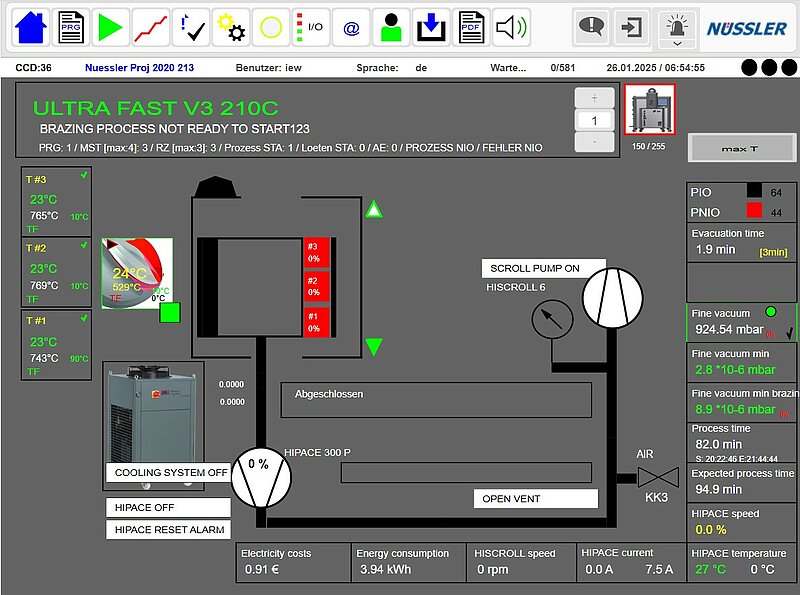

Another key feature is the resume function. In the event of a power or cooling water failure, the system resumes the process precisely at the interruption point – with no loss of quality and no scrap.

QUALITY IN EVERY DETAIL – INCLUDING SERVICE

IEW does not only deliver machines – but complete, well-engineered solutions:

• Customized fixtures, precisely tailored to each workpiece

• Material consulting & process development by in-house engineers and technicians

• Contract brazing on IEW’s own VVBM systems – ideal for companies without their own infrastructure

The contract brazing service offers maximum flexibility: from single pieces to serial batches, for prototypes or exotic materials. Customers benefit from short lead times, predictable costs, and the expertise of a team that fully controls every brazing parameter.

TECHNOLOGY MEETS COST-EFFICIENCY

Operating costs per cycle are only 4 to 8 euros, depending on energy prices. Due to the high capacity, the cost per tool is significantly reduced. The systems operate metal-free in a quartz glass chamber, eliminating the risk of contamination – a key factor for reactive materials or medical technology. Fully automated control enables precise monitoring, remote maintenance, and flexible adjustment of heating and cooling ramps – whether in SMEs or large enterprises.

APPLICATIONS – FROM CARBIDE AND PCD TO MEDICAL TECHNOLOGY

The VVBM series was designed for applications where precision and reproducibility are critical:

• Cutting tools with carbide, PCD, MKD, CVD, or CBN tips

• Brazing processes with ceramic materials

• Medical components with implant-grade surfaces

The ability to reliably join different materials simultaneously makes the systems a universal tool for modern manufacturing.

A COMPANY WITH TRUE PARTNERSHIP VALUES

IEW stands for Austrian engineering excellence combined with a genuine hands-on mentality. Martin Schweikhart and his team support customers from the first concept through to full production – with one clear goal: industrial-level process reliability combined with personal service. “Brazing must not be a blind flight,” says Schweikhart. “Our customers should clearly understand what happens during the brazing process – so they can keep their production under control.” This philosophy is embedded in every function of the VVBM series.

CONCLUSION

With the VVBM series, IEW offers a mature solution for safe, efficient, and highly precise manufacturing of diamond-tipped tools. The systems combine maximum temperature control with rapid cycle times, tailored customer support, and practical engineering expertise. Whether in-house or through contract brazing, working with IEW GmbH means reliability at every level – with a partner who not only masters the technology but also values true collaboration.

INTERVIEW

Mr. Schweikhart, what was the defining moment when you realized: “Vacuum brazing needs to be rethought” – and how did this insight translate into the VVBM series?

The aha moment didn’t come all at once, but was the result of a longer development process. For some time, we had been trying to braze diamond tools inductively under protective gas. This still worked with simple geometries, but with more complex, multi-edged tools we quickly reached the limits. The results simply weren’t reproducible enough, and the effort was out of proportion to the benefit.

That was the point when we realized: we needed a completely new approach – a system that not only runs stably from a process perspective but also convinces economically.

This led to the idea behind the VVBM series: short cycle times, high energy efficiency, and a well-thought-out process flow – all combined with maximum output. The fact that we have had more than 30 of these systems in use worldwide since 2018 confirms to us that we chose the right path.

The resume function sounds like a small detail with a big impact. Can you give us a practical example where this feature literally saved a customer’s day?

Absolutely, and this is not just a theoretical feature but a real game-changer in practice. We have customers in regions such as South America or parts of the USA, where depending on infrastructure, sudden power outages can occur. In the past, such an outage in the middle of the brazing process often meant complete scrap – sometimes with very high-value and expensive components.

With the resume function, we were able to significantly mitigate this problem. The system detects the exact point where the process was interrupted and resumes it precisely after power is restored – with no loss of quality. One customer once wrote to us that it literally saved their day, because a critical delivery had to go out on time. These are the moments when technical details translate into real, tangible advantages for everyday operations.

IEW is known for reliability and personal service. How do you ensure that this commitment is maintained in an international environment?

To maintain our reliability and personal service internationally, we work closely with local partners, for example in the USA, who support us on-site. In addition, digitalization makes customer support much easier: thanks to our remote-control systems, we can respond to customer requests quickly and efficiently. Of course, we also travel to the respective countries when necessary to meet customers personally and build a trusted relationship. For us, the most important thing is that our customers always feel well taken care of – no matter where they are.

Many of your customers operate in high-performance sectors. How important is energy efficiency in this context – and how do your systems contribute to sustainable production?

Energy efficiency is becoming increasingly important for our customers in high-performance manufacturing, and of course, we also want to contribute to that. Our IEW vacuum brazing systems are designed for maximum efficiency. Energy consumption is monitored and recorded throughout the entire process, so we can identify exactly where to optimize. In addition, unnecessary heating zones can be deactivated, and different tools can be brazed at varying temperatures in a single cycle. This way, our systems help save resources and enable more sustainable production.

You also offer contract brazing – an unusual combination for a machine manufacturer. What benefits does this bring to your customers?

Yes, that’s true. For a machine builder, it’s rather unusual – but that’s exactly what creates value for our customers: they can explore vacuum brazing without making a major upfront investment. Together, we develop and optimize the process, directly on their components. And once the method has proven itself, the decision to purchase their own system is no longer a gamble but a well-considered step – with a partner at their side who already knows the process first-hand. It’s a classic win-win situation. We encourage customers to challenge us and send their parts for a vacuum brazing trial.

From TU Vienna to your own machine series – what personally drove you to take this path, and what still motivates you today?

Like many others, after university I faced the question: what’s next? I was still relatively young, but during my thesis I had already realized that I enjoy working independently and taking ownership. The decision to become self-employed was bold, but in hindsight absolutely right – even if the early days as the managing director of a small company were, of course, very demanding. I got involved in everything from the ground up, and that’s what made it exciting: developing ideas, implementing technical concepts, building something from scratch.

Today, what motivates me most is the direct exchange with our customers – finding solutions together, responding to specific requirements, and ultimately seeing that our technology truly makes a difference. That remains a major source of drive for me.

![[Translate to English:] InDiamond.world](/fileadmin/_processed_/a/1/csm_InDiamond_Logo_2021_1fb017de30.png)