Efficient Machining of Hard-to-Process Nickel- and Cobalt-Based Alloys

When machining components made from costly nickel- and cobalt-based alloys, the reuse of resulting chips is of great importance. However, this reuse is significantly limited due to contamination from the use of conventional coolants and lubricants. Cryogenic cooling helps solve this problem and additionally improves the economic efficiency of the machining process.

"Machining processes generally represent raw material-intensive processing steps, often requiring up to 80% of the raw material to be machined away. However, the resulting chips are usually reused as raw material for other products through remelting.

In some applications, however, there are increased requirements for the purity of the chips to be remelted. This applies, for example, to products made from costly nickel- or cobalt-based alloys, where manufacturing companies often collect and remelt the chips in-house. For these products, the alloys are specifically composed to achieve the desired product properties. The tight tolerances of the alloy composition allow no impurities in the raw melts.

The current processes for machining nickel- and cobalt-based alloys are based on the use of water-miscible coolants and lubricants. These inevitably lead to contamination of the resulting chips with coolant and lubricant residues and also to an accumulation of carbon due to diffusion processes occurring during chip formation. As a result, the carbon leads to the formation of undesirable carbides, making the reuse of the chips previously impossible. Against this background, the use of cryogenic cooling with carbon dioxide presents a promising approach to solving this problem. The avoidance of water-miscible coolants and lubricants should prevent contamination of the chips. However, it must be demonstrated that the required machining operations can also be carried out safely and economically using cryogenic cooling."

In the framework of the funded project 'CryoEfficiency' (Grant No.: 033RK096C, funded by the BMBF under the 'KMU-innovativ' program), this topic was comprehensively studied at WHZ and is partially presented here. For the experimental investigations, a real component technology for the material TRIBALOY T400 was transferred to a demonstrator, on which various machining operations could be separately examined. This section focuses on the three relevant operations: roughing of the outer contour (longitudinal turning), finishing of the outer contour (longitudinal turning), and parting off the workpiece from the bar stock (transverse cutoff turning), as shown in Figure 2. All machining investigations were conducted on the RNC4 turning center from Monforts, which was specifically modified for the use of cryogenic cooling with carbon dioxide. The system allowed for external cryogenic supply (via nozzles) as well as internal supply through appropriate channels in the tool body (see Fig. 3). The evaluation of chip contamination due to coolant and lubricant use during machining was carried out in the project by carbon analysis through combustion (Leco CS744 system).

Experimental Analyses

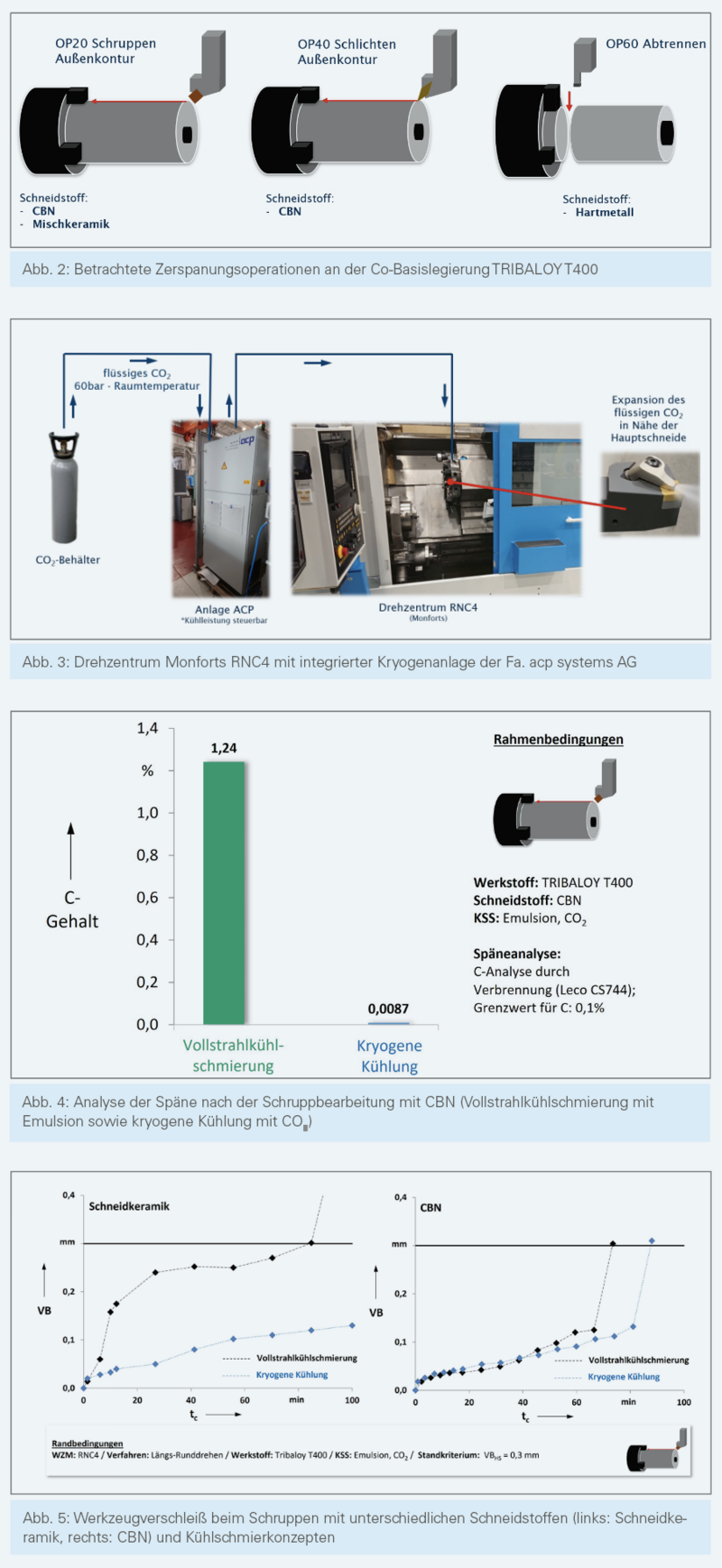

At the beginning of the experimental analyses, the industrially used machining technologies were implemented in the laboratory (full-jet cooling with emulsion) and then, under otherwise identical conditions, switched to cryogenic cooling. This allowed for a direct comparison of the resulting chips using different cooling and lubrication strategies. An evaluation of chip contamination can be performed as shown in Figure 4.

It has been shown that the carbon content in conventional machining, at 1.24%, significantly exceeds the limit of 0.1%, whereas the chips after cryogenic use, with a carbon content of about 0.0087%, do not reach this limit. Thus, the reuse of the chips is fundamentally possible by switching the cooling and lubrication strategy. However, it still needs to be clarified whether cryogenic cooling has negative effects on tool wear and component quality. Figure 5 shows the investigation results on tool wear during the roughing of the outer contour of the demonstrator with the two relevant cutting material variants, CBN and ceramic.

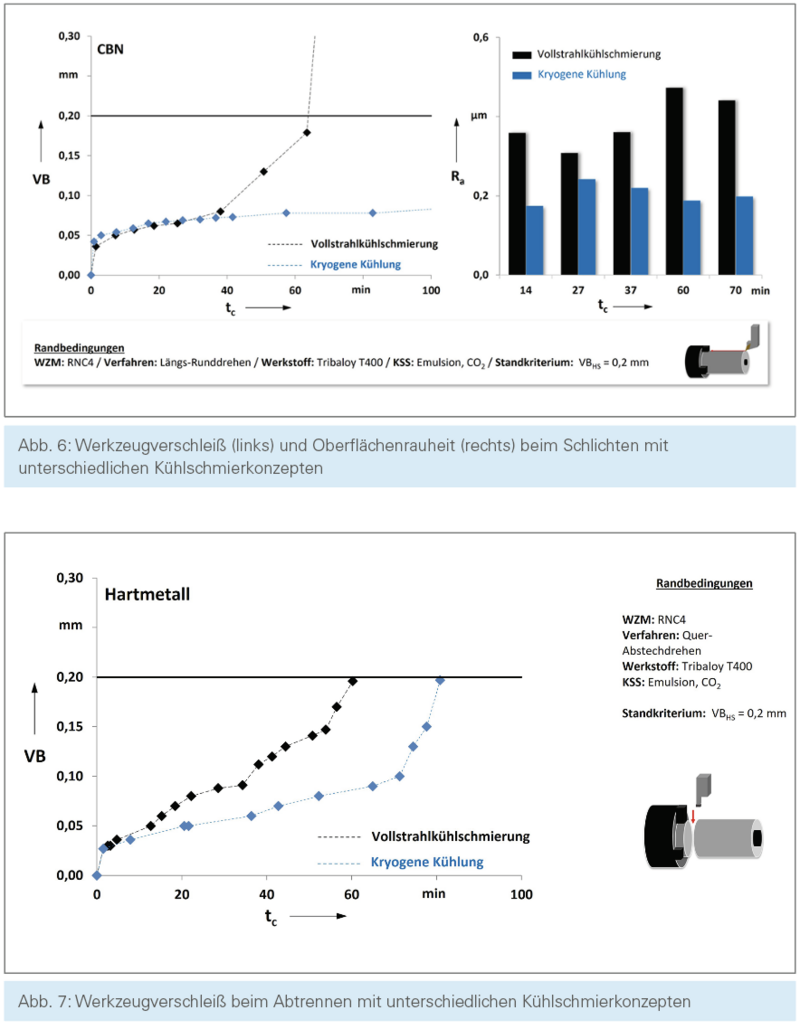

It is evident that cryogenic cooling leads to a significant reduction in tool wear compared to full-jet cooling lubrication. This effect is more pronounced with ceramic cutting tools than with CBN and may also be used to increase cutting speed. The results for the finishing operation are shown in Fig. 6. Here too, cryogenic cooling drastically reduces wear on the CBN tool, leading to significantly longer tool life and also opening up the possibility of increased cutting speeds (see Fig. 6 left). Regarding component quality, the measurement of surface roughness at different cutting times (see Fig. 6 right) during finishing also shows an improvement over conventional full-jet cooling lubrication with emulsion throughout the entire tool life.

The final consideration of the parting-off process (OP60 according to Fig. 2) is shown in the diagram (see Fig. 7). Even when using carbide cutting tools, there is a significant reduction in tool wear due to cryogenic cooling, resulting in an approximately 35% increase in tool life compared to full-jet cooling lubrication.

Conclusion

Given the need to ensure the highest purity requirements for the remelting of chips from costly Ni- or Co-based alloys, cryogenic cooling with CO2 was successfully applied in contrast to conventional full-jet cooling lubrication with emulsion. Analyses of tool wear and achievable component quality yielded positive results across different cutting materials. Switching component production to cryogenic machining is not only feasible but also holds significant potential for reducing both tool-related and time-dependent costs. A company within the project consortium has already begun this transition. Future experimental analyses of cryogenic machining of Ni- and Co-based alloys at WHZ will focus on potential increases in cutting speeds and the transfer of results to other high-hardness cutting materials.

Source: WHZ Zwickau

![[Translate to English:] InDiamond.world](/fileadmin/_processed_/a/1/csm_InDiamond_Logo_2021_1fb017de30.png)