Innovative vacuum brazing technology for high-performance diamond tools: The VVBM series from IEW GmbH in Austria

IEW Induktive Erwärmungsanlagen GmbH is setting new standards in the manufacture of precision diamond tools with its VVBM150 and VVBM200 vacuum brazing systems. The systems combine high batch capacities, excellent process control and economic efficiency – especially for applications such as polycrystalline diamond cutting (PKD), CBN, CVD, MKD or ceramic composites.

Key Features of the VVBM Series

Vertical Design & Maximum Batch Utilization

The vertically aligned vacuum chamber (360mm height for the VVBM200, 240mm for the VVBM150) enables optimal space usage. The VVBM200 can process up to 800 PCD inserts per cycle—up to 6 times the capacity of conventional horizontal systems. Parts can be arranged on up to 14 levels (≈25 mm spacing), offering greater flexibility for complex tool geometries. This allows for high-volume processing of both indexable inserts and more complex tools such as milling cutters.

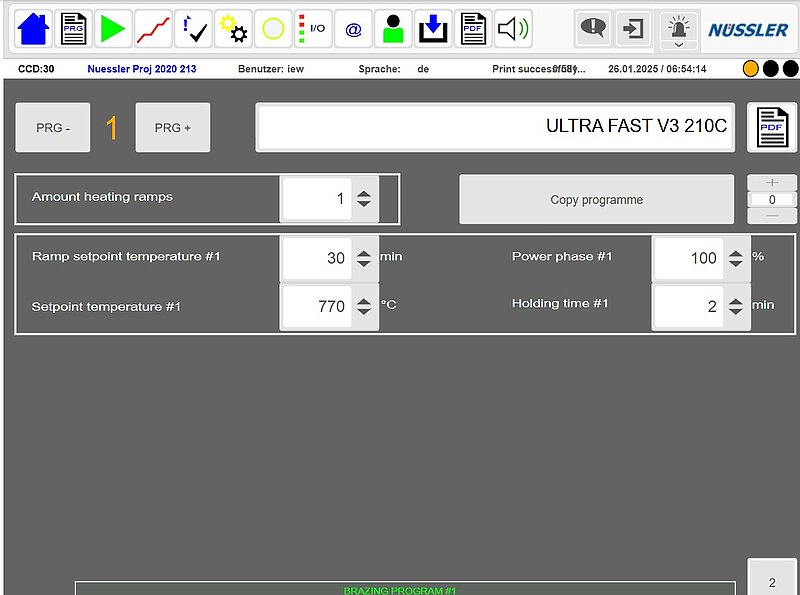

Patented 3-Zone Temperature Management

- VVBM200: Three independently controlled heating zones (each 120 mm high) with temperature uniformity <10° C.

- VVBM150: Also features three zones (each 80mm) with similar precision.

This allows different materials to be brazed simultaneously (e.g. PCD at <700° C and CBN/CVD at >800° C). The zone-specific control of alloys and temperatures reduces cycle times and increases energy efficiency.

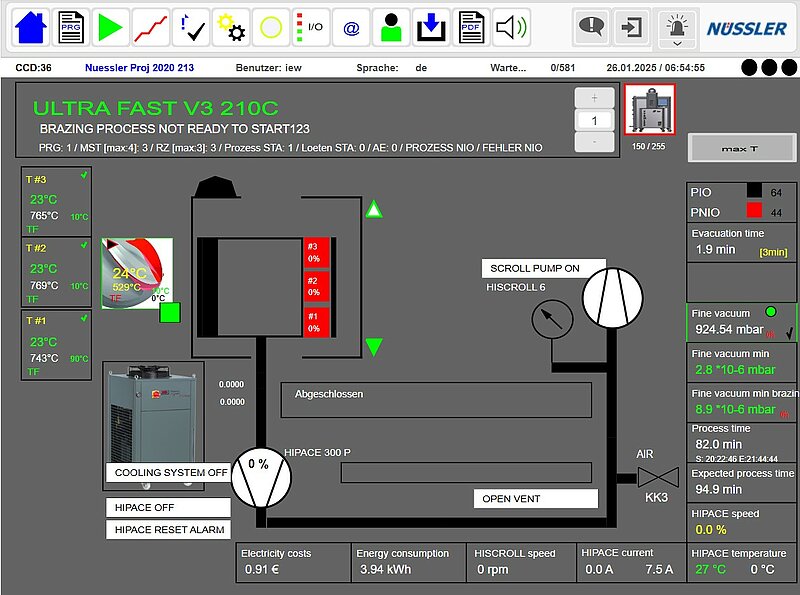

Vacuum brazing system VVBM200

Partial Pressure Control & Nitrogen Cooling (Exclusive to VVBM200)

- The partial pressure regulation prevents silver evaporation from active solders during high-temperature brazing (>800° C), ensuring consistent bond strength.

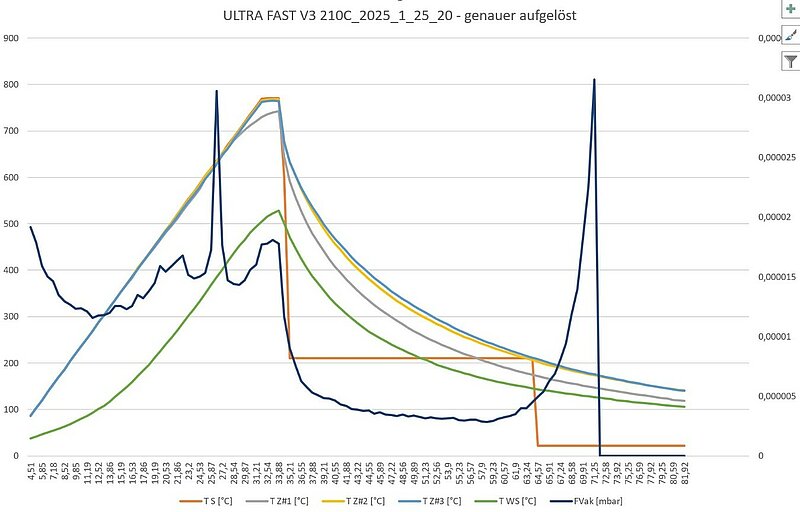

- Optional active nitrogen cooling shortens the cooling phase, reducing the total cycle time to under 60 minutes (including heating, brazing, and unloading).

Process Security with Resume Function

A newly developed resume mode allows interrupted processes (e.g. due to power failure) to continue precisely at the point of interruption. This minimizes scrap, reduces downtime, and maintains reproducibility—critical for sensitive materials like diamond or ceramic composites.

Cost Efficiency & Sustainability

Each brazing cycle incurs operating costs of only €4–8 (depending on electricity rates) for power, compressed air, and vacuum generation. High batch capacity significantly reduces unit costs, while the quartz-glass chamber eliminates metallic contamination and improves overall tool quality.

Technical Innovations in Detail

- Quartz Glass Chamber: The metal-free quartz chamber ensures maximum purity and is ideal for reactive materials. A built-in viewing window allows real-time monitoring during process development and quality control—available on both machines.

- Remote Control & Automation: Full remote operation via VPN software, including protocol logging and adjustment of heating ramps, holding times, and cooling rates.

- Scalability: The VVBM150 is ideal for SMEs with smaller batch sizes, while the VVBM200 is designed for industrial-scale production.

- Fast Cycle for Maximum Productivity: A key differentiator of the VVBM series is its fully integrated fast cycle—under 90 minutes from loading to removal of the brazed tools. This includes chamber heating, precision-controlled brazing, and rapid cooling. Compared to conventional systems—where cooling alone can take hours—IEW’s technology enables full cycle time optimization without compromising quality. Particularly relevant for mass production of indexable inserts with PCD or CBN cutting edges.

IEW-Services

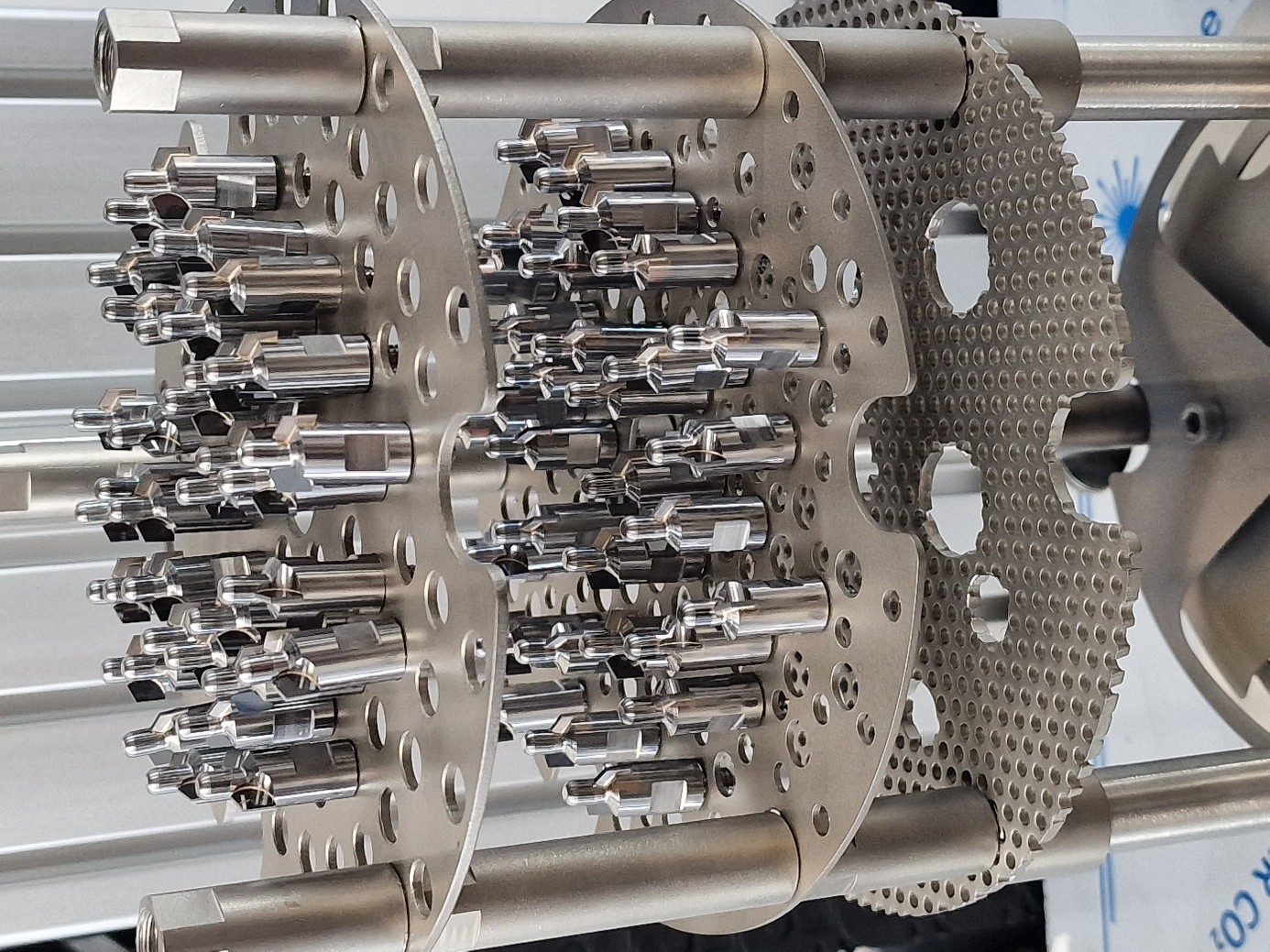

Custom Fixtures for Maximum Batch Efficiency

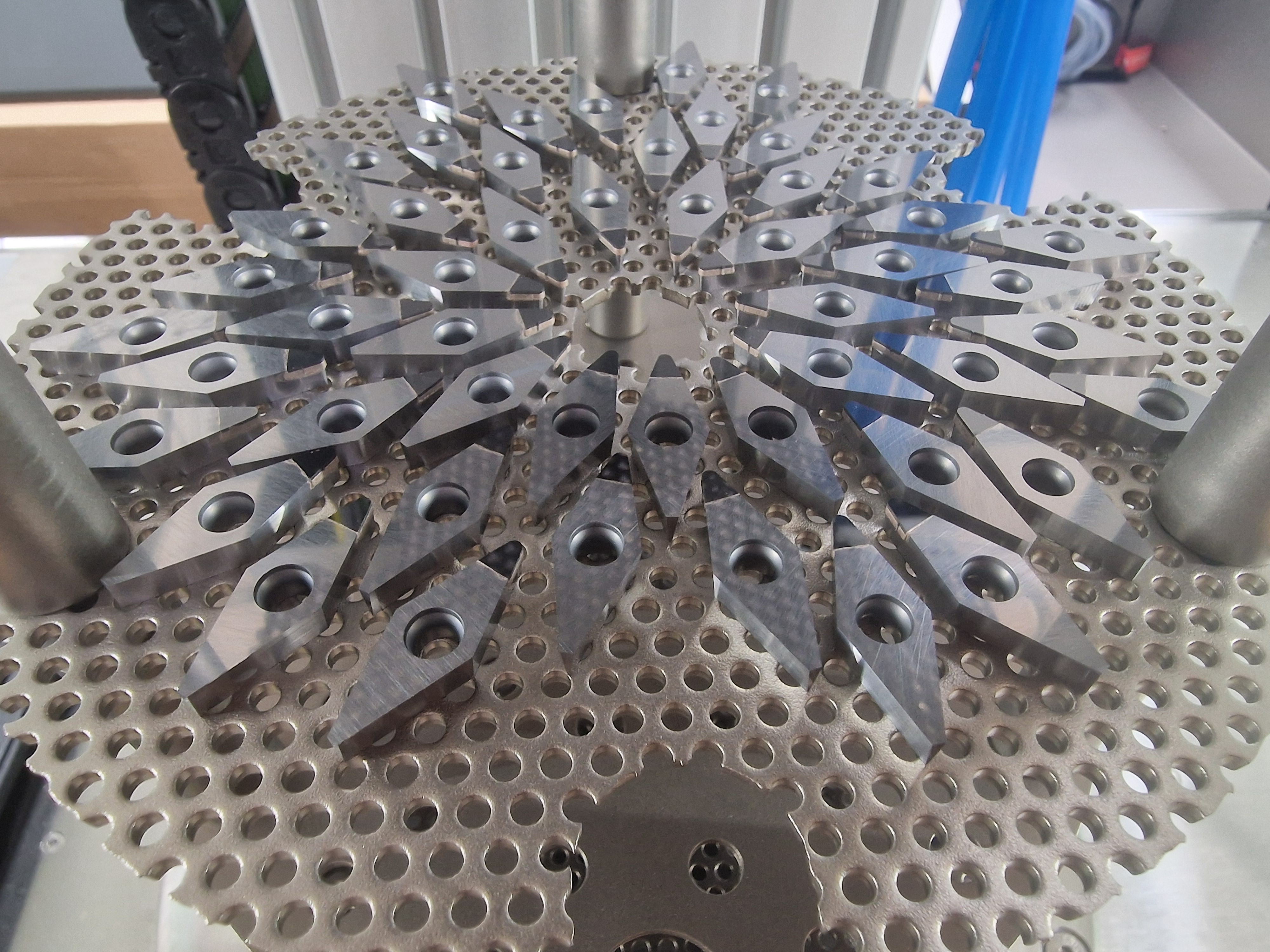

A critical success factor in vacuum brazing is tailored workpiece fixturing. IEW develops and manufactures precise fixtures that match your specific tool geometries and process requirements. Modular holders make the best use of chamber space—such as stackable holders for indexable inserts. These customized solutions not only maximize batch density but also ensure consistent quality—for both complex milling tools and small PCD inserts.

Customised tool holders

IEW – Experts in Brazing Technology & Materials Consulting

As a pioneer in inductive heating and vacuum brazing, IEW GmbH offers not only premium equipment but also comprehensive expertise in selecting and applying soldering materials. Our engineers provide personalized advice in choosing the ideal alloy. Through materials analysis and practical testing, we jointly determine the best combination of alloy and process parameters to ensure optimum brazed joints. This holistic consulting approach reduces scrap risk and ensures long-lasting performance of your high-end tools—from prototype to series production.

- Contract Brazing for Diamond Tools – Full-Service from a Single Source: In addition to designing and supplying high-performance vacuum brazing systems, IEW GmbH also offers contract brazing services for diamond tools. This service is ideal for customers without their own systems or with complex processes—such as exotic material combinations, special geometries, or prototypes. Using our in-house VVBM systems, we guarantee precision and reproducibility, backed by extensive know-how in alloy and fixture selection. From single batches to full-scale production, benefit from fast turnaround times, minimal capital risk, and the assurance that your tools are manufactured under industrially optimized conditions.

Vacuum-brazed tools

Applications & Economic Efficiency

The systems are ideal for:

- PCD, CBN, MCD, and CVD cutting inserts (e.g. for machining or woodworking)

- High-temperature brazing of ceramic composites or diamond tools

- Medical technology (implant-compatible surfaces)

Thanks to the patented 3-zone temperature control, diverse tools (e.g. PCD and CBN/CVD) can be brazed simultaneously at different temperatures, significantly reducing development time and energy consumption.

Conclusion

The VVBM series by IEW GmbH meets the core demands of modern diamond tool manufacturing: scalability, precision, and cost-efficiency. With its resume function, patented 3-zone temperature control, and optional nitrogen cooling, it sets new benchmarks in process reliability and throughput—especially in light of the growing demand for high-performance tools.

Vacuum brazing system VVBM150

Source | IEW Induktive Erwärmungsanlagen GmbH

![[Translate to English:] InDiamond.world](/fileadmin/_processed_/a/1/csm_InDiamond_Logo_2021_1fb017de30.png)