SLR Maschinen GmbH: Tailor-Made Solutions and Innovative Technology for Carbide Processing

For 15 years, Norbert Tretter has been the Managing Director of SLR Maschinen GmbH, a leading company in the development and manufacturing of grinding machines for centerless external cylindrical grinding, plunge grinding, and through-feed grinding. With a clear focus on customer productivity, the agile 15-member company based in Wertheim relies on tailor-made solutions precisely adapted to individual applications.

Tretter's career path makes him a true expert in grinding technology. Since the 1980s, the trained machine fitter and mechanical engineering technician has dedicated himself with passion and in-depth knowledge to achieving perfection in this field. His extensive practical experience—ranging from design, assembly, and service to contract grinding—forms the foundation of SLR Maschinen GmbH's innovative strength.

In this interview, Norbert Tretter talks about his many years of experience, the challenges of the industry, and how SLR Maschinen helps customers take their manufacturing processes to the next level.

DIAMOND BUSINESS: Mr. Tretter, SLR has now been under your leadership for 15 years, but the company actually has a long and fascinating history. How did this development come about, and which milestones were particularly significant?

Originally, SLR emerged from the company PeTeWe, which was founded in 1946 and specialized in the construction of optical profile grinding machines. In the 1980s, the business expanded to include the production of centerless cylindrical grinding machines. Toward the late 1990s, the profile grinding sector experienced such a significant decline that the centerless external cylindrical grinding division could not fully compensate for it. As a result, the company filed for insolvency in 1999 and was subsequently acquired by the Swiss machine manufacturer profiltec.

I was approached and asked if I would be willing to take over the centerless grinding division, including responsibility for a team of four to five people and sales. After careful consideration, I gladly accepted this challenge and was able to successfully expand the division. After about ten years, the company was sold again, and initially, no buyer was found for the centerless grinding division. This situation, however, laid the foundation for the establishment of SLR Maschinen GmbH. Could you tell us more about this turning point in the company’s history and how SLR Maschinen GmbH was founded?

I still vividly remember 2009. It was a time when I seriously considered leaving the company or even the entire industry. It became increasingly clear that no new investor would be found for the centerless grinding sector, and it initially seemed unlikely that machine production would continue. Additionally, 2009 was not exactly a booming year for the machinery market, which made the situation even more challenging. During this difficult phase, a supplier approached me with the idea of continuing the centerless grinding division. He was convinced of the quality of the machines and proposed becoming a shareholder, while I would take on the role of managing director and co-owner. Together, we founded an independent company.

At first, we were just four people, focusing primarily on the service sector. Step by step, we built up the mechanical and electrical design, established an electrical department, and expanded our team. This allowed us to grow continuously, and today, we are very proud to look back on 15 years of SLR Maschinen.

Mr. Tretter, over the past years, SLR Maschinen has grown from a small team into a company with 15 dedicated employees. In your opinion, which strategic decisions and measures were crucial for this growth and the company’s success?

Over time, we recognized the need to adapt our internal structures. In coordination with the shareholders, we decided to bring in external consulting to optimize our task distribution, create an effective organizational chart, and strategically place leadership roles. Our goal was to structure SLR in a way that ensures it remains operationally independent of specific individuals—especially myself. To support this, we engaged a coach who regularly trains and advises us on leadership topics. He has known our team for a long time, understands the individual strengths and weaknesses, and helps us deploy employees according to their skills.

One example of this approach is the promotion of Simon Buhl, a young designer whom we integrated into the management level. Thanks to external consulting, we can make decisions more effectively and develop targeted solutions. Additionally, we benefit from fresh ideas and new perspectives that significantly enhance our innovation processes.

A major milestone in our company’s development was the establishment of our own service department and a dedicated application technology department. We offer our customers not only machines but also comprehensive services, including maintenance and repair, which are becoming increasingly important. We ensure that our customers can always rely on our support. We provide customized training and conduct on-site inspections to optimize machine parameters and implement potential improvements. The increasing number of service orders confirms that the demand for expert support is growing. After all, our products are technically sophisticated solutions that require close and continuous consultation.

What else has changed?

The growing shortage of skilled workers, particularly the lack of qualified tool mechanics, metalworkers, and apprentices, poses significant challenges. Additionally, increased illness-related absences repeatedly disrupt our operations. To address these issues, we have begun creating detailed assembly instructions. This allows us to train new employees more quickly while maintaining and even improving our quality standards, which was sometimes difficult in the past without proper documentation. A few years ago, instructions were given directly by the master craftsman, but those days are over.

Effective knowledge transfer is now essential. We need comprehensive reference materials, but we also have to be mindful not to document every single detail, as a certain level of expertise can be expected. Striking this balance requires careful consideration to ensure both efficiency and quality in our machines.

Mr. Tretter, what distinguishes SLR machines, and what unique selling points do they offer compared to your competitors?

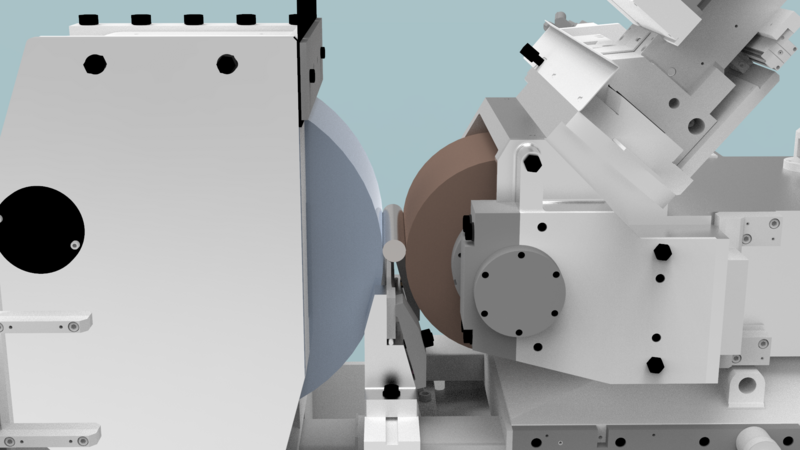

Our machines stand out due to their excellent price-performance ratio and are known for their stability and durability—genuine Made in Germany quality. Thanks to our flexible company structure, we can respond quickly to customer requirements and offer tailor-made solutions. Our many years of experience and in-depth expertise allow us to develop not just individual machines but comprehensive grinding solutions. These include integrating robotic cells to increase grinding autonomy, measuring units, and sorting systems that seamlessly fit into the production process.

Additionally, we have optimized our machines specifically for carbide grinding and conducted extensive testing to efficiently true diamond grinding wheels. This enables us to generate profiles for plunge and through-feed grinding directly on the machine—an area where competitors still face challenges. This innovation opens new possibilities in carbide processing.

Exciting developments in machine operation are also underway at our company: Our machines are now controlled by the modern Siemens Sinumerik ONE system. The intuitive menu navigation is developed in-house, allowing us to customize interfaces to meet individual customer requirements. Another highlight is our specially developed programming software, which makes it easy to create dressing programs for workpieces. We also offer the ability to store grinding data sheets as PDFs directly on the machine, enabling customers to conveniently access relevant values during grinding operations.

Our control system is fully designed for user-friendliness: Operation is via a touchscreen that functions like a smartphone, ensuring intuitive and efficient handling for our customers.

At trade shows, we present this technology through live demonstrations, where visitors can try out the control system themselves. This hands-on experience allows them to see the advantages and ease of use firsthand.

With this combination of innovative technology, customer-specific solutions, and state-of-the-art operation, we set new standards in machine usability—ensuring efficient and precise processes for your business.

Sustainability is becoming increasingly important for businesses. What concrete measures have you taken to operate more sustainably?

In 2021, we decided to build a large photovoltaic system, which allows us a high degree of autonomy in our power supply. This decision not only helped mitigate the impact of rising energy costs but also achieved significant CO₂ savings. Additionally, in 2024, we installed a new heating system powered by renewable raw materials. As a result, we have reduced our building’s CO₂ emissions by 92% and our primary energy consumption by 81%.

Interestingly, the impact of these measures goes beyond just energy savings. For instance, Creditreform considers these sustainability efforts in its ratings, strengthening our market position. Furthermore, we see our photovoltaic system as an important factor in promoting sustainability when selling our machines.

At which trade fairs are you represented? Will you be present at EMO this fall?

Every two years, we have been and continue to be exhibitors at GrindTec, now GrindingHub. However, we do not attend EMO since our focus is primarily on the European market. We are currently expanding our sales network in Europe and building strong local representations. Given EMO’s strong international orientation, it does not currently align with our strategy. Our goal is to systematically develop the European market.

Which regions or countries are currently your most important sales markets?

Our key markets are currently Germany, Austria, and Switzerland. Additionally, Eastern Europe plays an increasingly important role and is gaining significance.

How will grinding machines evolve in the future, and what market trends can be expected?

There will be a stronger integration of automation and digitalization to enhance machine efficiency and precision. This includes intelligent manufacturing systems and machine networking for improved process monitoring and control. Additionally, the demand for even more precise and high-quality end products will continue to grow.

With the development of new materials, such as composite materials and high-strength metals, the technology for centerless grinding will further evolve to meet these new requirements. Machines will increasingly be able to process these specialized materials efficiently and precisely.

Looking ahead, we remain committed to innovation and close collaboration with leading research institutions, such as the Tool Laboratory in Aachen. This enables us to make our machines even more powerful and precise. With this approach, we are well-positioned to meet the demands of Industry 4.0 and continue providing our customers with tailor-made solutions for the most demanding manufacturing processes.

![[Translate to English:] InDiamond.world](/fileadmin/_processed_/a/1/csm_InDiamond_Logo_2021_1fb017de30.png)