URMA A history of dedication, innovation and global success

Today, the Turin-based company manufactures diamond tools by processing industrial diamonds for mechanical engineering and metalworking. Customers are at the center of everything Urma does. Despite a change in ownership two years ago, the company's quality standards and vision remain unchanged.

Today, the Turin-based company manufactures diamond tools by processing industrial diamonds for mechanical engineering and metalworking. Customers are at the center of everything Urma does. Despite a change in ownership two years ago, the company's quality standards and vision remain unchanged.

Through strategic partnerships, innovative machinery, and new business models, the Italian company manages to increase its visibility far beyond the borders of Italy. Interest in the European market is enormous, and demand for dressing tools is steadily growing internationally. Perhaps it is precisely the combination of traditional products and innovative ideas that makes URMA an established brand. Trade shows play a crucial role for Urma in building networks and exploring new perspectives.

Success factors for optimal results

The success factors of the Turin-based company are obvious: one of them is to ensure the best selection and highest quality of diamonds by working closely with carefully selected, established suppliers and industry leaders worldwide. The company culture is also characterized by mutual respect and trust. Thanks to this atmosphere, the integration of new employees is swift, and knowledge transfer is highly effective. Another cornerstone of success attributed by Urma is its sophisticated internal organizational system, which encompasses all processes from raw material to end product, from engineering to sales, and to reliable customer service. Last but not least, Urma places great emphasis on the highest product quality, high adaptability and responsiveness, and continuously researches the development of further innovative ideas closely aligned with the needs of customers.

Challenges and Solutions

The upcoming years could indeed pose challenges for Urma, but the focus on customers will by no means be neglected. Digitalization within the company is being pursued with determination, and innovations will soon reach market maturity. In addition, the Turin-based tool company attaches great importance to renewing its website while improving and simplifying internal structures and processes.

Grinding Sector

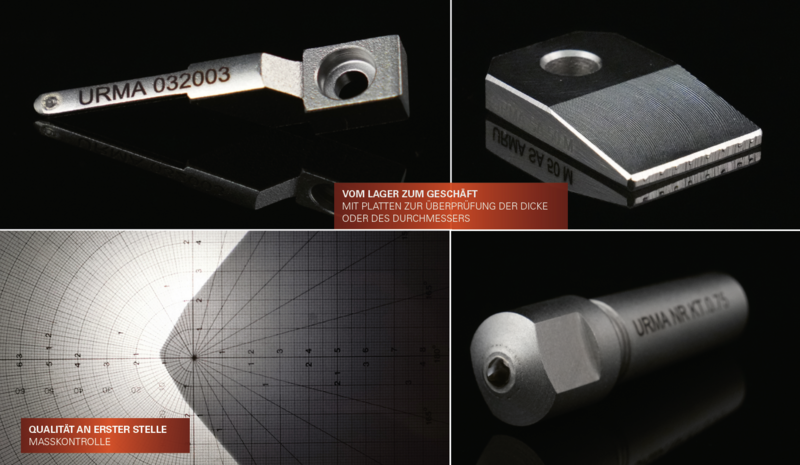

Urma specializes in the manufacture of high-quality tools for a wide range of dressing tasks. The range includes a variety of products, ranging from simple single-point dressing tools to custom-made special tools. Whether natural or synthetic diamonds are used does not matter.

Our range includes a variety of solutions, from rectangular to round, multi-layered diamonds, and other variants that help increase customer productivity. The diamond is still manually set and visually inspected, with tradition and years of experience forming the basis of this production process. In the Urma research and development department, work is currently underway on large dressing tools that will be used in the near future.

Customer Focus: Key to Success

The customer base ranges from small local companies to large corporations, with the highest emphasis always placed on quality and punctuality, regardless of the customers' location. Depending on the grinding machine, grinding wheel, and production conditions, we provide dedicated and tailored dressing tools. Urma sees itself as a solution provider and application specialist, providing advice on all questions relating to tool processing.

Internal Quality Processes

The selection of diamonds is of the utmost priority and undergoes a crucial phase accompanied by trained quality control. The experienced team carefully monitors both supplier deliveries and inventory. Each diamond is inspected by the quality department to ensure that the best possible option is always used. Assembly is done manually by highly skilled specialists, including a team of talented women who excel in their work. After a weekly phase in the sintering furnace, we then process the products using traditional milling and drilling techniques. Within a short time, the goods are ready for delivery. Additionally, we have a CNC machine available to assist with increasing demand. Special tools are used that function flawlessly across all product families. Upon completion of production, the quality of the entire offering is checked. The quality assurance team meticulously inspects each end product to ensure that only items in perfect condition are delivered. With the help of our specialized machinery and the expertise of our employees, we successfully complete the order.

Company Organization

With a dedicated team of 30 employees working in both production and administration, the Turin-based company looks confidently toward the current year. The trained sales team works closely with customers to develop tailored solutions. Internally, Urma places great emphasis on clear planning and organization to ensure smooth daily operations. Regular investments in training and continuous improvements, especially in the area of soft skills, are crucial for the company. These investments are vital to prepare employees for the increasing demands of the market. Urma has set ambitious goals and is convinced that it can handle a 20 percent increase in production without compromising existing processes. Therefore, the company sees itself well-equipped to meet the growing demands for precision and quality and plans to take a leadership role in the industry. With a strong team, a clear focus on customer needs, and a consistent commitment to continuous improvement processes, Urma is ready to face the challenges of the coming years, succeed, and grow far beyond the borders of Italy.

Source/Images: Laurence Dümpert

![[Translate to English:] InDiamond.world](/fileadmin/_processed_/a/1/csm_InDiamond_Logo_2021_1fb017de30.png)