Future-orientated further development of RayCutter systems at LaserPluSSS UG

LaserPluSSS UG is consistently continuing the further development of its RayCutter systems to meet the future requirements of the industry. After successfully converting existing systems to high-performance fibre lasers and implementing new functions for the efficient processing of tools with ultra-hard cutting materials, which also ensure improved laser quality, the next steps and innovations are now on the agenda.

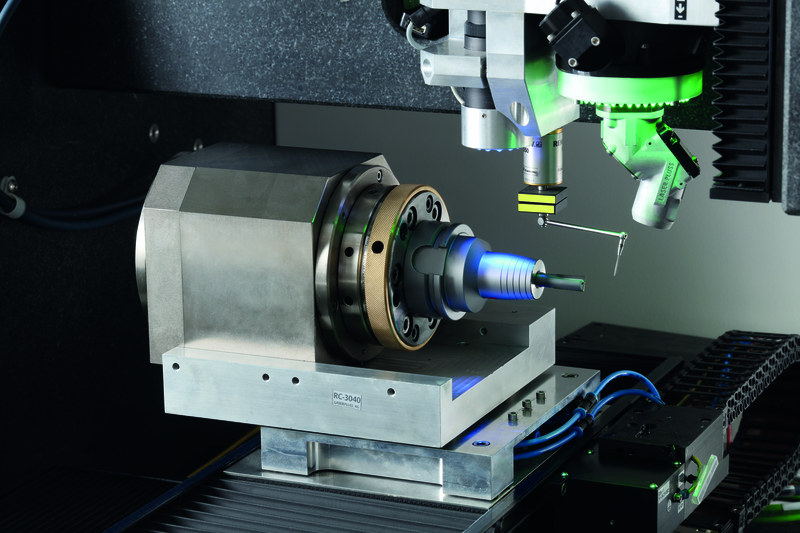

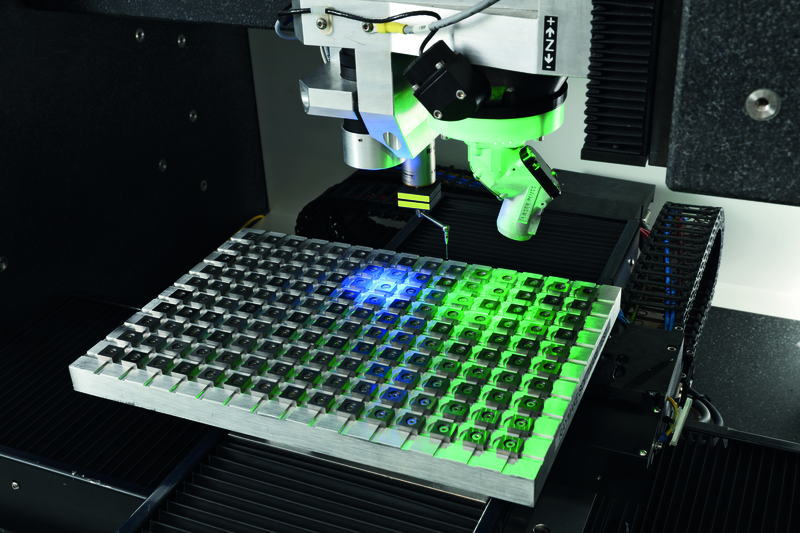

The RayCutter systems enable the efficient machining of up to 200 indexable inserts in a single clamping operation, without the need for additional automation or further user intervention. Particularly noteworthy is the flexibility to process different contours and materials on one pallet – a unique selling point in the market for diamond-tipped tools. Furthermore, the existing system can be used to fully process round tools with diameters from 1.5 mm to 220 mm. This is a decisive advantage, especially for small and medium-sized companies, as they often have limited options for operating several machines in a cost-effective and space-saving manner.

The RayCutter is capable of machining a wide range of materials, including PCD, CVD, PcBN, carbide, MCD and ceramic. It is suitable for both pre-cutting and finishing cutting edges and clearance angles. It can also be used for edge rounding, creating chip grooves and even labelling workpieces.

The important topic of energy saving was also integrated into the development. Thanks to targeted technical changes and adjustments, cooling systems and additional fans can be completely eliminated, resulting in savings of up to 50% on energy costs.

LaserPluSSS UG's range of diamond-tipped tool manufacturing services is complemented by the PreCutter series and the CutMaster systems. The PreCutters are equipped with laser sources ranging from 1.5 kW to 6 kW and enable the precise cutting of diamond circular blanks into individual segments with an accuracy of 0.01 to 0.02 mm – without the use of any additional operating materials. Compared to the previous processing with eroding systems, the PreCutter achieves an average time saving of 50% when cutting circular blanks.

The CutMaster systems are specially designed for smaller companies and offer a wide range of functions: they enable the cutting of circular blanks, the production of 3D geometries and fast labelling with a scanner system. The CutMaster thus combines the functions of several machines in a single device and offers this at an attractive price.

The whole thing is perfected by the specially developed software RayMake from LaserPluSSS UG. It combines a user-friendly programming interface with comprehensive job and production management, which enables efficient control of the manufacturing processes. In addition, integrated evaluation functions ensure a simple and fast analysis at the push of a button.

To continue to meet the growing demands on laser systems in the future, the team is working on the integration of a femto laser. This will not only enable the processing of ultra-hard cutting materials, but also a wide range of other materials. This opens up new possibilities for 3D processing, higher surface quality and much more.

Key features and benefits of the RayCutter

- Pre-cutting and finishing in a single step: All machining is done on a single system.

- Efficient pallet machining: Optimally suited for machining indexable inserts.

- Wide range of applications: Machining of round tools for a variety of requirements.

- Fast set-up times: Thanks to the innovative quick-clamping system.

- Precise cutting edges: chipping-free machining with minimal rounding of up to 2 µm.

- Compact design: the entire system requires little space.

- Energy and cost efficient: significantly reduces the manufacturing costs of tools.

Source | LaserPlusss UG

![[Translate to English:] InDiamond.world](/fileadmin/_processed_/a/1/csm_InDiamond_Logo_2021_1fb017de30.png)