Increase productivity with the HPR400 honing system from MAPAL

Three new solutions for practical use

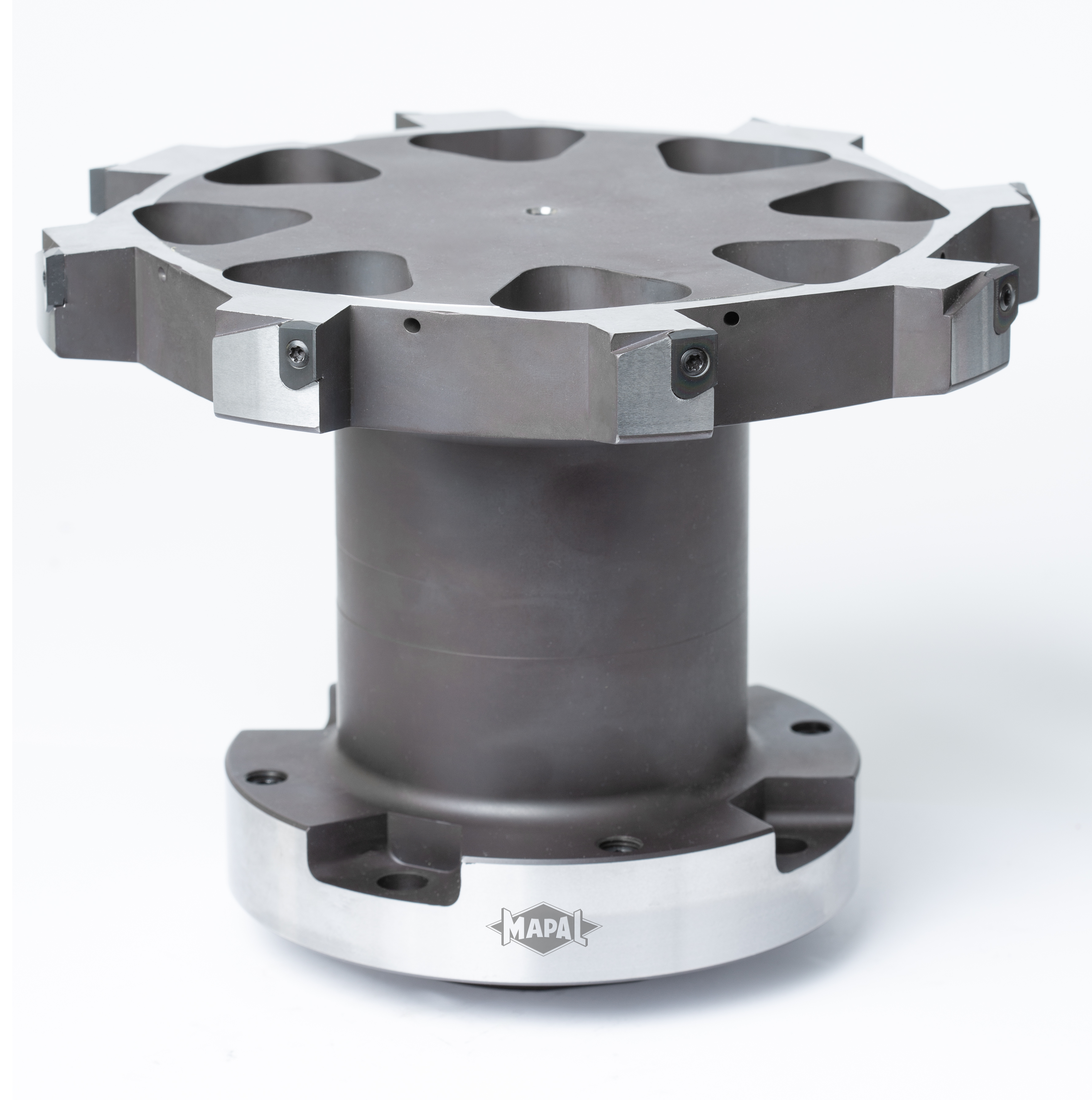

Complex processes and high quality requirements call for finishing systems that are powerful, precise and easy to use. With the HPR400 and HPR400 plus for highly productive reaming of large diameters, MAPAL meets precisely these requirements.

The multi-edged tool systems offer the advantage that the cutting edges with one (HPR400) or four (HPR400 plus) cutting edges can be changed directly on site by the customer and ensure maximum precision thanks to high-precision manufactured insert seats. Current developments are focusing on three new solutions, all of which pursue the same goal: to further increase the productivity of companies and reduce costs in the long term.

Innovative single-pass solution for finish machining with high allowances

In machining situations with high allowances in finish machining, the combination tool with ISO pre-cutting stage and HPR400 system is particularly attractive. It enables holes with up to 6 mm allowance to be produced in a single operation. The ISO cutting part takes over the main cutting, while the HPR400 system performs the finish machining. For the customer, this means the shortest possible cycle times. In addition, there is no need for adjustment, as the cutting edges on the entire tool do not need to be adjusted.

New HPR400 plus concept for face milling

The HPR400 plus series has been specifically developed for face milling. The indexable inserts have been designed explicitly for holes with special bottom contours (face milling or face milling). The new tool concept with two usable cutting edges improves cost-effectiveness. Despite face milling, the tool and cutting edge remain stable and reliable during machining. Applications can be found in almost all swivel bearings and bearing bores where clearance at the bottom of the bore must be guaranteed.

HPR400 with PCD cutting edges for machining stator housings: Innovative solutions for electromobility

The HPR400 system is also suitable for finishing the stator bore in electric motors. As there is now increased demand for motors in higher quantities for mid-range vehicles, the need for productive solutions is growing.

Unlike the cutting edges of a fine boring tool, the HPR400 tools with PCD cutting edges do not require adjustment. Due to the higher number of cutting edges, the machining speeds are significantly higher than with a fine boring tool. The technology enables higher output with less effort, thereby increasing productivity.

Flexible, economical, sustainable and technologically state-of-the-art

With the further developments of the HPR400 and HPR400 plus systems for specific applications, MAPAL underlines its claim to be able to offer customers in the automotive and fluid technology sectors future-proof solutions for a wide range of demanding machining operations – flexible, economical, sustainable and technologically state-of-the-art.

HPR400 plus flat cut: The HPR400 plus series has been specifically developed for flat cutting. The new tool concept comprises two usable cutting edges. Despite the flat cut, the tool and cutting edge remain stable and reliable during machining.

Source | MAPAL

![[Translate to English:] InDiamond.world](/fileadmin/_processed_/a/1/csm_InDiamond_Logo_2021_1fb017de30.png)