Innovations and Technologies of the Future: KLINGELNBERG at EMO Hannover 2025

EMO Hannover, one of the world’s leading trade fairs for production technology, will open its doors in Hannover from 22 to 26 September 2025. Under the motto “Innovate Manufacturing,” the fair will showcase the entire value chain of metalworking. This year marks the event’s 50th anniversary. Since its launch in 1975, EMO has stood for innovation, internationality, inspiration, and the future of metalworking. Organized by the German Machine Tool Builders’ Association (VDW) based in Frankfurt am Main, the fair regularly attracts trade visitors from all over the world and is considered an essential meeting point for experts and decision-makers in the industry.

At this year’s EMO Hannover trade fair, the mechanical engineering company Klingelnberg will present the precision measuring centers P 26 and P 40, the Höfler cylindrical gear roll testing machine R 300, the Höfler cylindrical gear grinding machine Speed Viper, and the Oerlikon bevel gear grinding machine G 30. In addition, ROTEC, a subsidiary of KLINGELNBERG AG, will showcase its solutions for the high-precision measurement and evaluation of rotational speeds and angular positions. The Smart Factory – the future of the manufacturing industry – will also be a key focus topic. By integrating IoT, AI, and real-time data analytics, factories are becoming smarter, more efficient, and more adaptable than ever before. Another highlight will be the further development of our tool systems and the modular kit concept for flexible internal gear machining. The Klingelnberg expert team looks forward to welcoming many visitors in Hall 13, Stand D68.

P 26 – For a wide range of gear and geometry measurement applications

Compact and tailored to the needs of the automotive industry, the P 26 precision measuring center is highly popular with customers. New measurement and evaluation methods, the implementation of innovative measuring systems, and consistent quality and reliability form the foundation of its decades-long success story. After more than 30 years, Klingelnberg is breaking new ground in machine control: the seventh machine generation is equipped with the latest Beckhoff control system, ensuring future readiness for current and upcoming expansions as well as compliance with the new EU Machinery Regulation. Due to their accuracy and reliability, Klingelnberg precision measuring centers are used worldwide not only by many customers but also as a reference by renowned metrology institutes. The well-established combination of tactile (3D NANOSCAN) and optical measuring technology (HISPEED OPTOSCAN) for measuring cylindrical gears is now available for this series in its latest development stage. In addition to optical pitch measurement, a continuous helical scan over the entire circumference and tooth width is also performed. This allows not only the profiles of all teeth but also the topography of all teeth to be captured. The significant time savings compared to tactile measurement and the resulting new possibilities in practice take deviation analysis for noise detection to a whole new level.

P 40 – Versatile all-rounder for reducing measurement times in series inspection thanks to hybrid solution

Introduced in 2020, the hybrid measuring technology was developed to meet the demand for higher measuring speeds while maintaining accuracy. The goal is to inspect the maximum number of components with the minimum number of machines. Hybrid measuring technology is continuously refined to expand its functionality and create additional value – with a focus on specific customer requirements.

All Klingelnberg precision measuring centers in the P 26 to P 65 series of the 6th and 7th generations can be optionally retrofitted with the optical sensor (HISPEED OPTOSCAN). Current precision measuring centers can optionally be equipped with this technology and the aforementioned measurement and evaluation features as standard. By consistently using the standardized GDE (Gear Data Exchange) interface for importing and exporting data and measurement results, Klingelnberg has set another benchmark in Measurement Technology 4.0 in the area of measurement result diagnostics and networking between production machines and measuring technology – the so-called Closed Loop.

R 300 – The Gear Noise Finder

The Höfler cylindrical gear roll testing machine R 300 reliably identifies the causes of gearbox noise resulting from poor gear quality. Due to its short measuring cycle, the R 300 can be easily integrated into any production process, enabling 100% quality control of manufactured gears. The R 300 is designed for all roll testing methods relevant to assessing the running behavior and noise characteristics of gears, including single-flank roll testing, structure-borne noise testing, and torsional acceleration testing. If required, double-flank roll testing can also be performed.

Depending on its configuration, the R 300 can inspect gears and shafts, which is particularly important for components from the eDrive powertrain. 100% quality control generates significantly more data than random inspections. For data analysis and reporting, R 300 measurement results can be processed using Klingelnberg’s Gear Noise Analyzer (GNA) software, and tolerance limits for production monitoring can be defined.

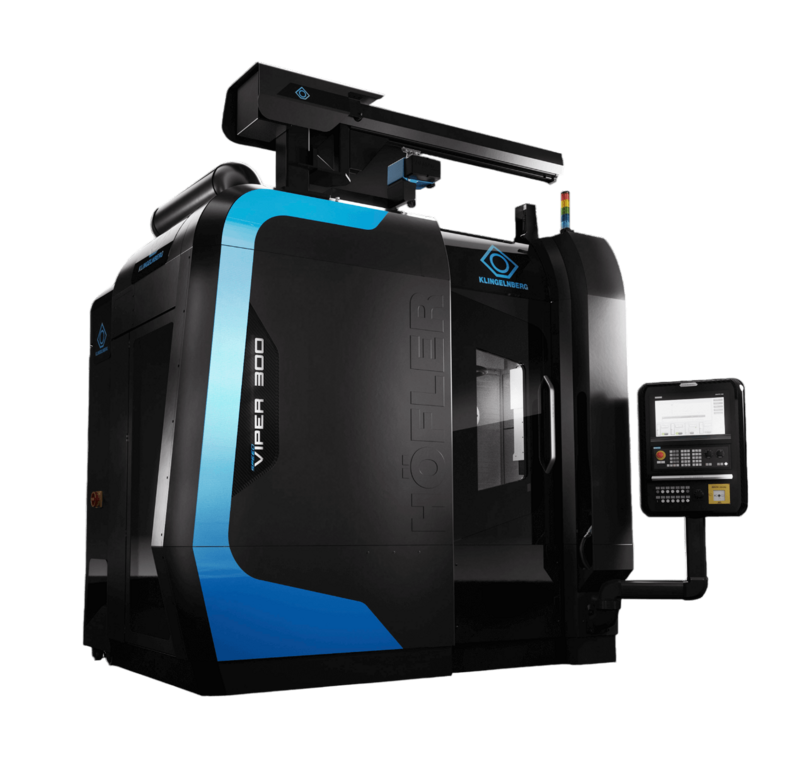

Speed Viper 300 – For highly productive generating grinding in large-scale production

The Höfler cylindrical gear grinding machine Speed Viper – focused on highly productive generating and polishing grinding in large-scale production – is available in three different machine types, depending on individual requirements: Speed Viper 300 as a single-spindle version, and Speed Viper² 180 and 80 as double-spindle versions. Depending on the model, the Speed Viper can handle maximum workpiece diameters of 80, 180, and 300 mm. With the double-spindle concept of the Speed Viper², the shortest possible non-productive times are achieved.

The Speed Viper can also be equipped with partial or full automation with an automation interface according to VDMA 34180 standards. The machine software Gear Operator and a process-oriented operator guidance system with wizard technology enable simple operation, even for the most complex applications. Finally, modern drive and control technology guarantees maximum energy efficiency.

G 30 – Quiet Bevel Grinding for noise optimization of ground bevel gears

With Quiet Bevel Grinding, Klingelnberg offers a method for noise optimization of ground bevel gears. Through low-frequency harmonic variation of the machine kinematics from gap to gap, the topographies of individual tooth flanks are modified individually. As a result, not just a single tonal frequency is excited, but the sound energy is distributed across additional frequencies. Similar to lapped gear sets, the resulting noise resembles multifrequency noise, which is perceived as much more pleasant from a psychoacoustic perspective.

For production, Quiet Bevel Grinding has the advantage of being implemented without affecting cycle time and without impairing gear measurement. Due to the targeted distribution of modifications around the circumference of the component, the proven Closed Loop can be applied without issue.

ROTEC measurement systems – Precise speed and angle measurement

Klingelnberg’s subsidiary Rotec will present its solutions for the high-precision acquisition and evaluation of rotational speeds and angular positions. The angle-based measurement approach and order-domain data processing are particularly suitable for analyzing rotating components, determining transmission errors in gears, performing single-flank roll tests, and analyzing drivetrains. The Rotec measurement system includes rotational speed sensors, signal conditioning, the modular measurement system RASdelta, and the measurement and analysis software. In addition, the Rotec engineering team offers complete measurement projects as an external service provider.

Smart Factory – The future of manufacturing

The Smart Factory is revolutionizing product development, manufacturing, and delivery processes. By integrating IoT, AI, and real-time data analytics, factories are becoming smarter, more efficient, and more adaptable than ever before. From predictive maintenance to minimize downtime to digital workflows for process optimization, the Smart Factory enables higher productivity, lower costs, and improved quality. The future of industry is not only automated but also connected, data-driven, and optimized for peak performance. At EMO Hannover, the expert team will present this new solution.

Advanced tool systems – Solutions for every challenge

The performance of a machine depends on the quality of the tools and clamping devices used. That is why Klingelnberg is also setting new benchmarks in this area – with the highest precision, reliability, and innovative technology.

Visitors to EMO Hannover can expect not only a comprehensive range of new products in the areas of machinery, quality, and software solutions but also groundbreaking developments and innovations in tool systems.

Source: Klingelnberg

![[Translate to English:] InDiamond.world](/fileadmin/_processed_/a/1/csm_InDiamond_Logo_2021_1fb017de30.png)