The future of production: Mitsubishi Electric at AMB 2024

Mitsubishi Electric's Mechatronics CNC and Mechatronics Machinery divisions are opening the doors to the digital future of production and presenting advanced solutions for increasing the efficiency of production processes. At this year's AMB in Hall 7, Stand C 71, Mitsubishi Electric will be presenting pioneering technologies that make production fit for the future.

Welcome to the 'Mitsubishi Electric City' - The Mitsubishi Electric stand at AMB 2024, C71 in Hall 7

The completely new stand concept invites visitors to explore the 'Mitsubishi Electric City' - an interactive presentation in which the latest solutions can be experienced in four themed areas: Simple, Smart, Connected and Partnership. Each theme offers the opportunity to familiarize yourself with the technologies that are driving the transformation of the industry. In addition to modern erosion systems, high-performance CNC controls and drive systems, the company is developing other solutions that are already opening up new opportunities for its customers to remain competitive in the long term. Intelligent digitalization solutions will be presented that support users in overcoming challenges such as increasing cost pressure and a shortage of skilled workers. Examples such as the traceability of products, the certification of processes and the documentation of sustainability make it clear that digital solutions are also essential in these areas.

The demands on the manufacturing industry are becoming ever more complex, while the shortage of qualified specialists is constantly growing. Intuitive programming is becoming increasingly relevant in manufacturing in order to meet these challenges. In the Simple theme block, Mitsubishi Electric shows how these challenges can be mastered in a simple way through intuitive programming. Particularly noteworthy is the Simple Programming Solution in the CNC area, which makes it possible to create G-code without in-depth programming knowledge. The innovative CAM solutions XEDM for direct use on the wire EDM machine and XpressCAM as a counterpart for work preparation will be demonstrated in real use on the EDM systems.

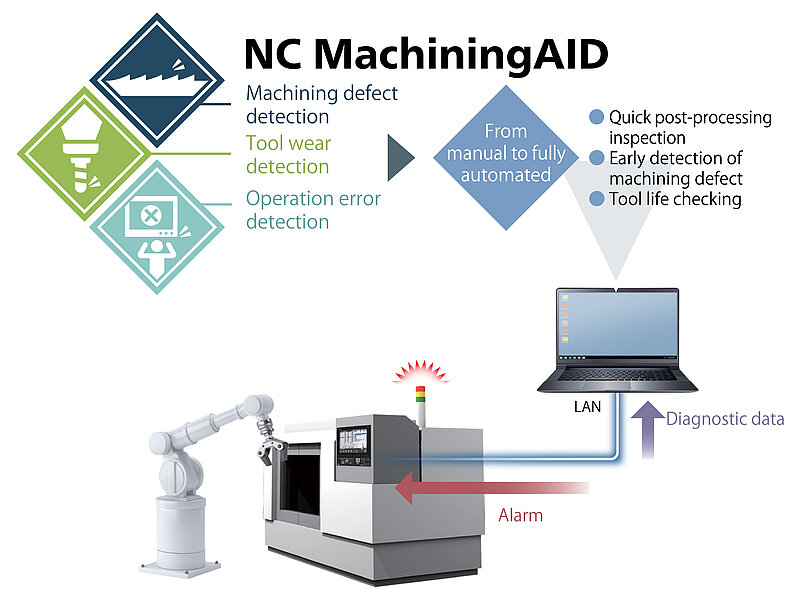

Mitsubishi Electric's pioneering technological role in the field of AI and networking is reflected in the Connected theme block. The aim is to collect, process and analyse machine data and use it for significantly more efficient, optimized and self-learning production. Significant progress has already been made in this direction with the NC Optimizer, NC Virtual Simulator and NCMachiningAID software solutions. Mitsubishi Electric's answer to artificial intelligence is MAISART - an advanced solution that serves as the basic foundation for these developments and is already integrated into many of the company's software solutions and products. MAISART stands for “Mitsubishi Electric's AI creates the State-of-the-ART in technology” and is an AI platform that integrates various machine learning and artificial intelligence technologies. It offers advanced machine learning algorithms developed specifically for industrial applications.

Intelligent solutions for the use of data from production plants and processes, including those from partners, will be presented in the Smart theme block. The digitalization platform from WBA, Aachener Werkzeugbau Akademie GmbH, will be presented for the first time in combination with the eroding systems from Mitsubishi Electric. WBA develops and markets manufacturer-independent software solutions for the intelligent analysis of process data in one-off and small-batch production and their targeted application to optimize manufacturing processes.

As a reliable partner, Mitsubishi Electric also ensures that products are resupplied efficiently and reliably. The company is known for the high availability and reliability of its machines and components. Nevertheless, unforeseen events can occur over time. To meet these challenges, Mitsubishi Electric offers customized services that are precisely tailored to the customer's needs and even exceed them. This includes special training, individual maintenance plans and customized technical solutions. One example is the comprehensive repair of “old” electronic assemblies to new spare parts, which ensures that even older machines can continue to be serviced reliably. At AMB, the Mechatronics Machinery division will also be presenting a training program for EDM specialists aimed at companies that have difficulty filling vacancies.

With three modern EDM systems from its current production program, Mitsubishi Electric combines the digital future with advanced mechanical engineering. The MX900 is celebrating its European premiere at AMB - an oil bath wire EDM system that impresses with outstanding precision, reliability and performance. This innovation is aimed at customers in precision toolmaking as well as service providers in precision manufacturing and the watchmaking industry. The MP1200 Connect wire EDM system, which is designed for tight tolerances, also impresses with maximum precision and reliability. Together, the MX900 and MP1200 Connect represent the ideal solutions for modern toolmaking that focuses on precision and cost-effectiveness.

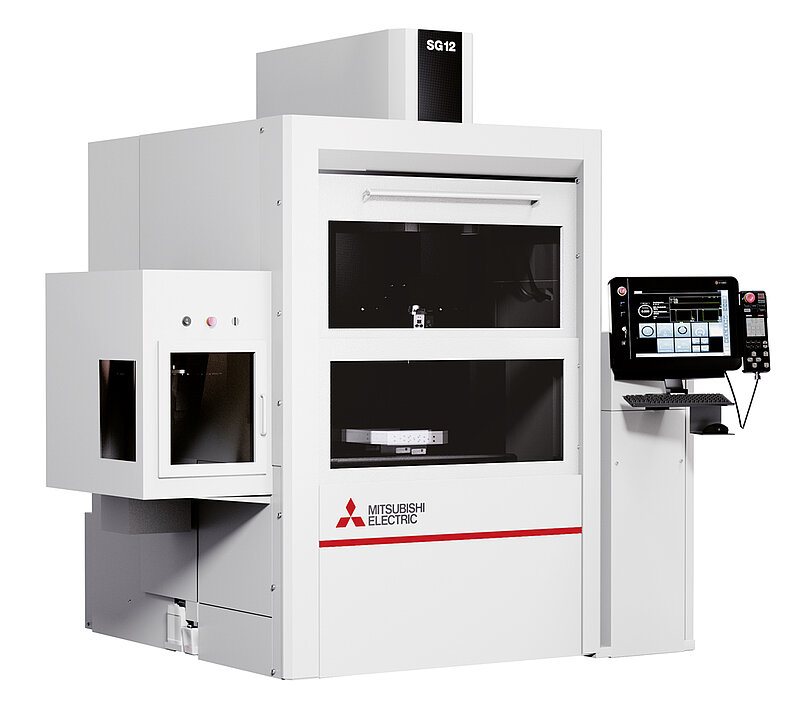

The SG12S die-sinking EDM machine, a fully equipped all-rounder for mold making and beyond, offers simple operation and programming as key benefits. Here too, an intelligent control strategy, integrated job planning and efficient evaluation of a wide range of operating data, including post-calculation, help to further optimize processes.

At Mitsubishi Electric, the focus is on people, even in times of advanced technology. The company relies on trust, transparent communication and long-term partnerships, which characterize all aspects of its work. A claim that visitors to stand C 71 in hall 7 at AMB 2024 in Stuttgart will be able to see for themselves.

Quelle: Mitsubishi

![[Translate to English:] InDiamond.world](/fileadmin/_processed_/a/1/csm_InDiamond_Logo_2021_1fb017de30.png)